In a study of a Danish wastewater treatment plant a computer simulation shows how a potential energy saving of more than 50% can be achieved. Bruno Kiilerich and Eddy Yang discuss how these savings could be made by changing from a medium speed small diameter propeller to a slow speed, large diameter propeller flowmaker.

There is a major concern about energy use and greenhouse gas emissions as a result of not just climate change but activity in the water, as well as other sectors. Ambitiously, the Danish water sector branch organisation, DANVA has a vision that this sector should become carbon neutral before 2025. Already in 2007 they setup a target for 2013 stating that the water sector should reduce the energy consumption by 25%. The water sector uses in all around 2.4% of the total electric energy consumed in Denmark, which corresponds to around 800 GWh and a resulting CO2 emission of around 470,000 ton CO2/year.

Of the intended savings in the water sector most should be found within wastewater treatment as this consumes around 65% of the total energy used in this sector in Denmark. This corresponds to approximately 1% of the total amount of electric energy used in Denmark per year.

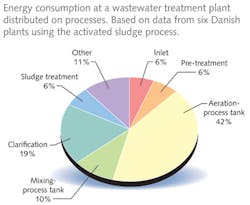

Of the 65% of electricity consumed at the treatment plants in Denmark around 10% of this is used for mixing in the process tanks (see figure below). This amounts to around 50 GWh used for mixing in process tanks in Denmark. In some cases it will be possible with simple measures to save as much as 50% of the energy just by replacing existing small diameter medium speed mixers with large diameter slow speed mixers. This will be revealed in the following study of a Danish wastewater treatment plant.

Mixing in the process tank of Drøsbro

Drøsbro is a small wastewater treatment plant located in Denmark. It is a biological plant with both nitrogen and phosphorous removal, but without other kinds of sludge treatment than pre-dewatering. The plant consists of a single process line with a total capacity of 10,000 PE (population equivalent). Of this capacity around 7,000 PE is currently used with 388,395 m3 of wastewater treated in 2010.

The wastewater treatment plant uses 274,426 kWh per year which corresponds to 0.7 kWh/m3 or approximately 39 kWh/PE. All process zones are equipped with medium speed Grundfos AMG mixers that ensure that solids are kept in suspension. The central SCADA system controls the four mixers with a timer controlled operation schedule of 20 minutes working time followed by five minutes of pause. For this work, it is only the mixer in the aerobic tank that has been studied further.

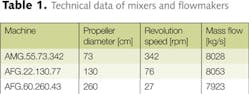

The aerobic zone in the process tank at Drøsbro is designed to have a constant circulating flow. For mixing in these kinds of tanks basically two types of equipment can be used: mixers with medium rotational speed and a small propeller diameter (AMG) and flowmakers with low rotational speed and a large propeller diameter (AFG). It is investigated how increasing the propeller diameter and lowering the rotational speed will influence the flow field. To make this comparison, two different two-bladed flowmakers were chosen. The rotational speed of the two flowmakers was adjusted to provide approximately the same mass flow rate as for the mixer.

CFD simulations

Using Computational Fluid Dynamics (CFD) a computational model can be built that represents a system that can be studied in more detail. As a result we can analyse the results and see what impacts there are from changing the operation conditions and agitation method. In general, CFD provides the possibility to simulate turbulent fluid flow, multiphase flows, heat and mass transfer, chemical reactions, acoustics and fluid-structure interaction.

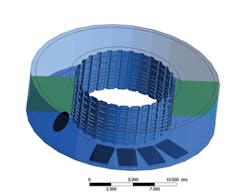

The tank at Drøsbro wastewater treatment plant is built of pre-fabricated concrete elements from Perstrup Beton Industri A/S and the 3D model is constructed based on appropriate detail drawings of these elements.

During operation of the process tank two different flow conditions can be considered. One is where the fluid is just agitated in the tank and the other one is where compressed air is added to the fluid through rows of diffuser discs at the bottom. In the first case the flow conditions will develop into a steady state open channel flow.However, as is evident that in open channels smaller fluctuations in the flow field will occur but the overall flow will be more or less uniform over time. A steady state CFD simulation, which has been used in this study, will therefore capture the overall picture of the flow field and the result will resemble the general flow conditions found in the tank.

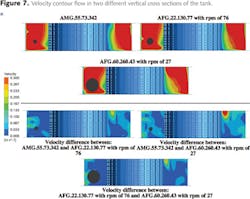

In the other case where air is supplied through the diffuser fields the flow will be heavily dominated by this and the flow has to be considered as fully transient. Comparing the flow fields in this case can only be captured by transient CFD simulations which will not be treated in this paper. For the steady state simulations a turbulence model has been used to capture the turbulent diffusion of the flow. For each of the simulations performed a horizontal velocity contour plot in a position 0.3 m over the tank bottom plate has been visualised together with two vertical cross sections of the raceway.

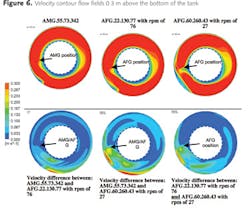

One cross section is placed before the mixer (left) and another is placed after the air field (right) (see 3D model for positions). For visualising the difference in propeller diameter between the three machines, the propellers have been highlighted with black on the CFD simulations.

Depending on the proceeding primary treatment it is accepted practice to keep an average velocity between 0.2-0.3 m/s over the bottom plate of the tank as an indirect measure of when suspended solids in the tank will not settle. The flow velocity magnitudes have been visualised based on the colour bar, where velocities above 0.3 m/s are coloured with red.

When comparing the results of the three different machines having a similar mass flow we observe a more or less equal flow field with only smaller variations 0.3 meters above the bottom plate. As expected the velocity will be lower at the centre of the tank due to the centrifugal forces of the circulating water.

Low velocity zones shaded in blue are located in approximately the same positions and having almost the same areas and magnitudes as are high velocity zones marked with orange and red for the three different machines.

Only the AFG.60.260.43 deviates a bit from this picture as can be seen when the velocity differences are visualised. However, this deviation might be due to the fact that the mass flow of the AFG.60.260.43 is around 1.5% lower compared to the two other machines in this study.

Yet when looking at the bulk flow in the tank judged by the cross sections below, it seems that at the right cross sections, the low velocity zone coloured in blue towards the centre of the tank is reduced as the propeller diameter is increased, which is further supported when looking at the plot of the velocity differences.

At the cross sections to left there are on the contrary only minor differences in the flow fields between the three different machines. However the AFG.60.260.43 again deviates a bit from the velocity fields of the two other machines.

Based on the CFD analysis doubling propeller diameter, keeping an equal mass flow, does therefore have neither a significantly positive nor a negative effect on the flow field.

As the flow fields are approximately equal, independent of the propeller diameter, and thus the possibility and position of sedimentation in all three cases will possible be the same. The determining factor for which equipment to install in the tank should purely be based on lifecycle cost of the machine or accumulated cost over a given period of time.

Savings and Lifecycle cost evaluation

Above velocity flow fields of the AFG.22.130.77 was based on an adjusted revolution speed of 76 rpm in contrary to the nominal rpm of 77. For the following calculations, data corresponding to nominal speed of the AFG.22.130.77 has been used, which to a small extend will favour the AMG.55.73.342 in below comparison as the energy consumption at 77 rpm is marginal higher that at 76 rpm.

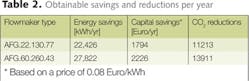

To estimate the saving potential, the line power, P1, according to the data sheets of the products are used for the calculations when possible. Here it is evident that the AMG.55.73.342 uses 5.7 kW and that the AFG.22.130.77 uses 2.5 kW during operation.

For the AFG.60.260.43 with adjusted rotational speed, it is not possible to read out P1 directly from the product data sheet. But as the efficiency is almost steady in the allowed operating range between 30-50 Hz and the turn down to 27 rpm corresponds to a frequency of 31.5 Hz, P1 for the adjusted AFG.60.260.43 can be calculated using the affinity laws.

Based calculations, the use of the AMG mixer in the aerobic zone of the tank consumes around 14.6% of the total energy at the plant. If in contrary an AFG.22.130.77 was installed, mixing in the aerobic zone will only consume around 7% of the total energy at the plant whereas installation of an AFG.60.260.43 with reduced revolution speed will reduce this even further to around 4.8%.

Besides the energy and thus the capital that is being saved by installing one of the AFG slow speed flowmakers compared to the current installed AMG medium speed mixer, the emission of CO2 corresponding to 0.55 kg CO2/kWh (based on Danish conditions) will also be a saved.

Without having performed a thorough CFD analysis of the anoxic process zone at Drøsbro, which also has an unrestricted circular flow, it can be speculated whether a 50% reduction in energy also can be achieved here, thus reducing the overall energy consumption even more.

Payback time for replacement of an AMG with an AFG

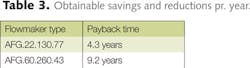

When calculating the payback time for replacing the AMG with one of the AFG's it is besides the price of the specific equipment, price of energy and cost of capital also necessary to account for the cost of additional needed installation accessories, cost of a frequency converter as well as cost of the actual installation/replacement.

With a price for electricity of 0.08 Euro/kWh having an assumed steady increase of energy prices of 5% per year and a rate of interest of 5% the calculated payback times are shown in below table.

With an expected lifetime for the flowmakers of 20-25 years the savings implemented by changing to an AFG.22.130.77 will contribute positively on the accounts plenty of years after the payback time which makes this investment quit attractive. With the AFG.60.260.43 a further energy saving can be achieved but the payback time is not as attractive when the alternative with the AFG.22.130.77 exists.

This is due to the fact that only part of the capacity of the machine is utilised and the energy savings are not sufficient to compensate for the higher cost of the flowmaker itself, the price of the frequency converter as well as the need for more sturdy installation accessories compared to what is needed for the AFG.22.130.77.

Payback time for installing an AFG compared to an AMG

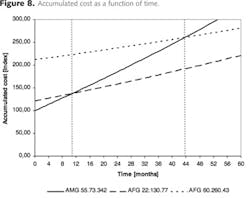

For new installations and upgrade projects it is another situation. A comparison has been made by looking at the accumulated cost per month (figure 8), thus the initial cost of equipment and installation accessories plus the operational cost, where the energy prices are expected to increase with 5% per year.

From this calculation it can be observed that significant savings can be achieved by installing an AFG.22.130.77 compared to the AMG.55.73.342. In less than 12 months, the higher investment of the AFG.22.130.77 will be justified due to the lower energy consumption during operation.

Even with the investment and need for a frequency converter the payback time of the AFG.66.260.43, will in this case only be around 44 months. However, considering the radial flow that will arrive at the propeller, due to the circular tank shape and the resulting flow velocity gradient that arise over the propeller, it makes a flowmaker with a diameter of 2.6 meter a less attractive alternative than a flowmaker with a diameter of 1.3 meter as there is no extra improvement in the flow velocity distribution in the tank.

Conclusions

Based on analysis of velocity flow fields using Computational Fluid Dynamics it has been shown that for Drøsbro wastewater treatment plant a replacement of the AMG.55.73.342 to an AFG.22.130.77 in the aerobic zone can reduce the total energy used for mixing at the plant from 14.5 % to 7 % without altering the flow field and thus the mixing of the tank. The payback time for implementing this exchange of equipment in the aerobic zone of the plant will be around four years. For Drøsbro this will lower the key performance figures from 39 kWh/PE to 36 kWh/PE. Furthermore it will reduce the emission of CO2 with around 11,200 kg/year which minimises the burden on the environment.

Based on findings in this study, process tanks with unrestricted flow could potential find easy and economical justified energy savings by using low speed large diameter propeller flowmakers compared to medium speed small diameter propeller mixers despite the higher initial cost of a flowmaker.

Author's note: Bruno Kiilerich is application specialist in the application utility and Eddy Yang is development engineer, structural fluid mechanics for Grundfos Management. The authors would like to thank Favrskov Forsyning for granting access to Drøsbro wastewater treatment plant as a vital part of this work.