Modular Desalination: Small Packages, Big Energy Gains?

The growing demand for smaller desalination systems has led to a number of companies developing containerized systems. KSB claims its entry to the market can achieve up to 75% energy saving and does not require two electric motors to drive booster and high pressure pumps. WWi takes a look at the technology.

Research from the International Desalination Association (IDA) has forecast the market value for containerized desalination plants in 2013 to be US$830 million, with an annual growth rate of 15%.

The benefits of containerized systems are clear compared to large scale, fixed infrastructure: they are designed to provide a method of producing low cost drinking water, quickly and efficiently. Large plants, in comparison, can take longer in planning, construction and require considerable upfront investment costs.

The phrase of the “tourist dollar" has been used in connection with many industries – restaurants, hotels, famous landmarks – and is actually the lifeblood of many of these businesses. Yet, commonly unnoticed is the strain the influx of tourists can put on a town, city or country's water sector. KSB believes this is where there lies a huge opportunity here for containerized filtration.

“The global market for containerized desalination plants is fragmented and obtaining accurate data is difficult", comments Wojciech Golembiewski, project manager Salino, KSB. “Taking the tourism industry as an example, there are many holiday resorts around the world where fresh water has to be constantly available but the costs of building and operating large desalination plants are prohibitive. With containerized desalination plant, hotels, resorts and manufacturing sites can be independent of regional water supply companies and have total control over their requirements and costs."

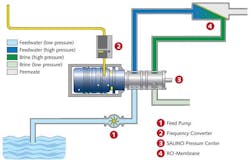

Figure 1. Seawater enters the pressure center at 2.5 bar and is raised to 70 bar and then transferred into the RO membrane

As a result, the pump and valve manufacturer has developed a compact high pressure pump unit for Reverse Osmosis (RO) seawater desalination. Called the SALINO Pressure Center, it has been developed for RO systems with the capacity to produce of up to 1000 m³/day of permeate.

The unit operates by receiving pre-treated seawater via a feed pump with the salt concentration typically being in the region of 38,000 ppm. The seawater enters the pressure center at 2.5 bar and is raised to 70 bar and transferred into the RO membrane where the brine is separated from the water to produce permeate.

The resulting high pressure brine produced in the membrane is returned to the pressure center where its mechanical energy is recovered, contributing to raising the pressure of the incoming pre-treated seawater.

The Pressure Center is a hydraulic system that is designed to provide pressure boosting and energy recovery. The big question is how?

KSB claims it is down to combining all the elements in a single unit and reducing the number of components, thereby reducing the complexity of pipework and installation costs.

By removing the need for a separate booster pump and motor, it is claimed, the number of components associated with other types of systems is reduced and energy savings of up to 75% are made compared to systems that do not use an integral energy recovery device. Because there is no fluid exchange between the brine and the feed water, energy-consuming mixing is avoided, according to the manufacturer.

So here's how it works. The system combines the four elements required in the RO process for seawater desalination: a high pressure pump, an electric drive, together with a booster pump and an energy recovery device.

The container solution employs a single lubricant-free axial piston pump and single axial piston motor, the latter serving as an integrated energy recovery device. “As a result, three of the elements are fulfilled by one and the same unit: creating high pressure, compensating pressure losses and recovering energy," the company says.

The entire system runs on a single electric motor and frequency inverter and the electric drive has a rating of 29 kW, not requiring a separate booster pump.

What about fluctuating salt contents in various seawaters? KSB says they can be processed by a response through the integrated control system. In tests the unit desalinated one cubic meter of seawater with a salt content of 35,000 ppm at a power input of approximately two kilowatts per hour.

According to the company, extensive development and field tests have been underway at various Middle Eastern sites since the start of 2013, with the first units operating close to the Red Sea.

With IDE Technologies having launched its modular PROGREEN desalination solution back in 2011, and claiming success (see leader focus on page 10), many water firms are turning their hands to a small solution for potentially a big market.