Sewage treatment operators are being challenged to rethink their assumptions about wastewater grit particles that could be the unknown cause of huge operating inefficiencies.

Hydro International is among the world's leading authorities in advanced grit separation and grit removal. Leading grit removal experts at IFAT 2014 will question conventional assumptions and demonstrate the energy savings that can be achieved with proven innovative, technologies.

"Operators are almost certainly allowing more harmful grit to pass through their inlet works than they realise, leading to costly equipment wear, higher energy use and increased maintenance costs. They literally may not know what they are missing," says Hydro International business director Clive Evans. "We are laying down a challenge: Let us change your mind about grit removal. The result could be huge savings in operating costs."

Do you know what you're missing?

"The latest scientific research into the true nature of wastewater grit is overturning conventional thinking," explains Evans. "Particle size, shape, specific gravity and composition all influence settling velocities and affect removal efficiencies. Taking out finer grit particles than has been accepted practice could result in better plant performance and energy efficiency.

"Fine grit removal could be considered an essential part of a plant's energy consumption reduction plan. Energy costs can account for 50% of a plants operating costs and removing the amount of sediment that has to be pulled unnecessarily around the plant can reduce power costs substantially."

Fine grit removal

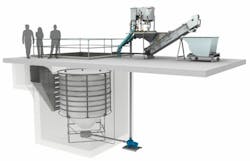

Hydro International offers a high-performance portfolio of grit removal, grit washing and de-watering technologies. New to Europe but already proven in North America, the space efficient HeadCell® modular, multiple-tray settleable solids concentrator requires no power and has no moving parts and targets grit as small as 75 microns. It is widely accepted as the 'next generation' grit separation technology.

The Hydro Grit King® is an advanced hydrodynamic vortex separator that augments gravitational forces to separate grit from water with minimal headloss. With a simple free-standing vessel or constructed chamber design, it achieves low operating and maintenance costs.

"Ideally, 90% to 95% of all grits, sands and fine particles should be removed at the inlet to the wastewater treatment plant," Evans continues. "Wind-blown grit, dust and sand in a wide range of particle sizes is typical of climates in Europe, the Middle East and around the world. The particles lodge in open drainage systems such as ponds, channels and highway drainage and are washed to the treatment works.

"Grits and sands cause extensive and costly problems to mechanical equipment. Grit abrasion of metal surfaces causes premature wear in pumps, bearings and valves. Grit settles in low flow pipes and tanks, causing blockages and plant downtime. Sludge settlement and digestion processes are disrupted by the build up of heavy inorganic sediments."

Advanced vortex technologies

Hydro International's grit removal technologies provide solutions for wastewater treatment plants based on vortex separation technologies developed by Hydro over more than 30 years of continuous research and development. A range of advanced solutions from Hydro International are available, based on vortex technologies which have made the company's name.

With no external energy requirements for operation, no moving parts, minimal maintenance and low lifetime costs, vortex technologies have helped to transform stormwater and wastewater treatment in the UK and North America and are increasingly being adopted worldwide.

www.hydro-int.com