After 11 years in operation, a reverse osmosis (RO) desalination plant in the Canary Islands needed a refurbishment to increase capacity, reduce energy and maintain the quality of drinking water produced. This article looks at the analysis of the selected RO membranes and the resulting energy saving after installation.

By Blanca Salgado, Juan Manuel Ortega, Jasna Blazheska, Joan Sanz and Verónica García-Molina

Seawater desalination by means of Reverse Osmosis (RO) membranes has always been challenged by its association with high energy consumption values. In order to reduce the cost of water production and maximise the efficiency of desalination by reverse osmosis, membrane manufacturers have been researching to reach higher permeability, especially for seawater applications, where operating pressures and the resulting energy consumption are critical factors.

The Canary Islands Seawater Reverse Osmosis Desalination plant was designed and built by Veolia Water Systems Ibérica, back in 2003. The plant includes a beach well, followed by a pre-treatment consisting of pressurised dual media sand filter and a cartridge filter 5µm. It was originally equipped with a high pressure pump with variable frequency drive and Pelton turbine as energy recovery device.

With a configuration of four pressure vessels, each of them with seven elements per vessel, the plant was originally equipped with Dow Filmtec SW30HR-380 elements. The original production capacity was 400 m3/day of permeate water and, since a different energy recovery device was installed, the average specific energy consumption recorded was 4.9 kWh/m3 of permeate water (whole installation including pre-treatment).

The permeate water produced is used for drinking water purposes and to comply with the local regulations, the permeate water Boron levels were below 1 ppm. Concerning the TDS (Total Dissolved Solids), the values registered were below 400 ppm.

After 11 years in operation, in 2014 the plant was requiring a revamp. Once again, Veolia Water Systems Ibérica was responsible to upgrade the installation. This upgrade included the substitution of the existing high pressure pump and existing energy recovery device, the installation of a different energy recovery system, together with the loading of a new set of seawater RO elements.

The revamping of the installation had three objectives: increasing the capacity of the unit, reducing the specific energy consumption requirement, and maintaining the quality of the permeate water produced. Through its delegation in the Canary Islands, the Technical Direction of Veolia Water Systems Ibérica, together with Dow Water and Process Solutions technical service, evaluated alternatives with regards to the change of seawater RO elements.

The configuration selected for the RO membranes, included a hybrid combining two types of elements: Dow Filmtec SW30XHR-440i were installed in the first three front positions of the pressure vessel, while Dow Filmtec Seamaxx elements were installed in the four rear positions.

The aim of the new configuration, during the project planning and execution, was to offer a design able to comply with the local regulations in terms of permeate water quality, while ensuring increased capacity and reducing the specific energy consumption. The design calculations were performed with Dow Filmtec's Reverse Osmosis System Analysis -- ROSA software. Besides the change of RO elements, the high pressure pump with frequency converter and Pelton turbine was replaced by a new generation exchange pressure system I-SAVE 40 with a high pressure pump APP-24, both from Danfoss.

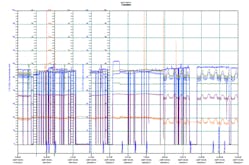

For the follow-up of operational parameters of the unit, besides the control by PLC, corresponding HMI and associated instruments (conductivity, pressure, flowrate and differential pressure), Veolia Water Systems Iberica installed as well a Data-Logger from Jumo, with software PAC-3000.

This Data-Logger registers and stores the most representative data for the follow-up and control of the plant: feed and permeate flowrates, permeate conductivity, feed and concentrate pressure, and total specific energy consumption (including pre-treatment).

Also, the following information is recorded manually, with appropriate frequency: raw water temperature and conductivity both in the raw water stream to the plant and the feed to RO elements (so the percentage of mixing in the energy recovery device is monitored), and the individual energy consumption associated to low pressure pump, high pressure pump and energy recovery device.

Operational performance evaluation of RO elements

The revamping work was performed and finished in the beginning of 2013. The new set of RO elements, including Seamaxx was installed and put in operation in May 2013.

The performance of the desalination plant will be compared, with the performance of the previous elements, and also to Dow Filmtec's Reverse Osmosis System Analysis -- ROSA simulation software and DOW FT-NORM normalisation tool.

The performance of the RO membrane system is recorded continuously, and frequently normalised by means of FTNORM. Data of the first days of operation once the system was stabilised have been taken as reference values for normalisation.

The new configuration including Seamaxx elements, despite the increase in production capacity to 550 m3/day of permeate water, provides average specific energy consumption values of 2.1 kWh/m3 of permeate water (including pretreatment and RO section). The quality of the permeate water produced is still compliant with the local drinking water regulations.

Plant performance vs ROSA

Besides the follow-up of the operational parameters by the means of FT-NORM, the plant follow-up has as well been done by comparing its actual performance with operation projections (using Reverse Osmosis System Analysis -- ROSA software from Dow).

The evaluation of operational pressure and observed permeate quality is performed through the calculation of average equivalent ROSA Flow Factor (FF). This is as well as the comparison of permeate water quality as per expected through ROSA and TDS/Boron content in permeate samples, taken and evaluated both Tarragona's Dow Water & Process Solutions R&D Lab and in external certified laboratories.

The evaluation of the observed operating pressure when compared to ROSA Flow Factor calculation leads to equivalent values of 1.12 to 0.96 since start-up. The ROSA Flow Factor is understood to reflect multiple phenomena such as slight changes in membrane permeability during service life as well as the impact of fouling. Note no chemical cleaning (CIP) has been performed since the start-up of the unit in May 2013.

The comparison of ROSA simulations for the permeate water quality and the values measured from the samples taken in different moments of the operation of the unit since start-up show very similar values both in terms of TDS and Boron. The quantification of the deviation (measured value vs value obtained from the simulation) is leading steady calculated deviation, in the ranges of 3% to 12%.

All the activities performed for the revamp of the plant, including, but not limited to the replacement of eleven year old Dow FILMTEC elements by an Internally Staged Design (ISD) including Seamaxx have led to a decrease in specific energy consumption from 4.9 kWh/m3 to 2.1 kWh/m3. This included an increase in the production flow rate of 150 m3/day.

Blanca Salgado and Verónica García-Molina are from Dow Water & Process Solutions, Spain, Juan Manuel Ortega and Joan Sanz are from Veolia Water Solutions and Technologies and Jasna Blazheska is from Universitat Rovira i Virgili, Escola Tècnica Superior d'Enginyeria Química, Tarragona, Spain.

More Water & WasteWater International Archives Issue Articles