A Czech Success Story: Nanoparticle Tech Helps Groundwater Decontamination

This article examines the contribution made by the Regional Centre of Advanced Technologies and Materials at Palacký University in the Czech Republic to nanoscale zero-valent iron (NZVI) technolog to chlorinated solvent and chromium (VI) ground water decontamination projects.

By Huw Kidwell

Nanotechnology is rapidly becoming the single-fastest growing sector of the global high-tech economy. There are already more than 1600 reported consumer products that use nanomaterials for medical, personal, and military applications and the number is growing every day.

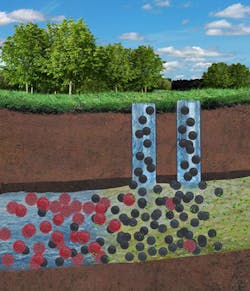

Nanoparticles are defined as particulates with dimensions of less than 100 nanometres (nm). They are particularly useful in hazardous waste site remediation and contaminant reduction because of their small size and large surface area per unit mass.

Using reductive particles (5-40 nm) in the remediation of pollutants such as chlorinated hydrocarbons and heavy metals found in groundwater aquifers is not new but the The Regional Centre of Advanced Technologies and Materials (RCATM) have been able to combine several technologies into a practical commercial process.

Technology & partners

The Czech Republic has always been a giant in developing new technology and the Regional Centre of Advanced Technologies and Materials at Palacký University has continued this trend by using state-of-the-art nanotechnology to address environmental water issues across the Czech Republic. As part of the Czech NANOBIOWAT program they partnered with nine other institutions both academic (e.g., Technical University of Liberec) and commercial (e.g., AquaTest, AECOM CZ. MEGA and GEOtest) to develop a practical solution to water remediation.

The process has been tested on a full-scale site and has subsequently moved into commercialisation. The patented technology uses a simultaneous effect of biotic and abiotic reductive species (i.e., zero-valent iron particles and lactate) to treat groundwater contaminated by chlorinated hydrocarbons and some heavy metals. The method is based on the combination of three, well understood complementary processes:

- A reductive process using air-stable iron particles (i.e., nanoparticles or a combination with micro particles)

- Biotechnology utilising lactate for chemical assistance in biodehalogenation

- An electric field enhancement of the reductive process and migration of iron nanoparticles.

This technology is particularly good for removal (chemical degradation) of organic solvents - chlorinated hydrocarbons (typically dichloroethylene (DCE), trichloroethylene (TCE) and perchloroethylene (PCE)), and also for inorganic contaminants such as arsenic, hexavalent chromium, and dissolved metals like copper.

Iron nanoparticles can be used to eliminate unwanted eutrophication of surface water (removal of phosphorus and killing of cyanobacteria including elimination of toxins). Generally, this technology is particularly good for reducible compounds and for groundwater (or other types of water where there are anoxic conditions).

How did it start?

RCATM was established in 2010 from the Centre for Nanomaterial Research at Palacký University under the direction of Professor Radek Zbořil. Joint research into tunable zero-valent iron nanoparticles had been underway since 2005. Then in 2006, driven by the lack of iron nanoparticles on the market for groundwater treatment, cooperation was established.

Scientists from the Centre for Nanomaterial Research at Palacký University were responsible for nanoparticle synthesis and complex characterization, while scientists from TUL and AQUATEST performed the nanoparticle testing for reductive degradation of chlorinated hydrocarbons in groundwater environment. The scale-up of nanoparticle synthesis from a few grams to multi-kilogram was the next logical step.

A cooperation with LAC (a manufacturer of industrial furnaces) led to the design of a unique furnace for zero-valent iron nanoparticles synthesis by thermal reduction of suitable powder precursors. NANO IRON was established in 2008 to focus on the development of new environmental applications of Fe(0) nanoparticles, including technical support.

NANO IRON produces five products including: three zero-valent iron products, with and without surface stabilisation and organic surface stabilisation as well as a nano-micro particle composite and also a Ferrate oxidative/disinfecting particle.

Dr Jan Filip currently leads the Environmental Nanotechnologies Group of the Regional Centre of Advanced Technologies and Materials.

Speaking to WWi magazine, he says: “The important change in research strategies came with founding of the RCPTM (2010) (i.e., the change from small Centre for nanomaterial research into well-established research Centre with state-of-the-art instruments and computation methods for understanding the interaction of iron nanoparticle surfaces with pollutants and solvents)”.

Dr Filip explains that the success of their technology is due to three factors. “Our cooperation with Technical University of Liberec and AQUATEST due to the lack of iron nanoparticles on the market for groundwater treatment was an ideal start for us. The establishment of NANO IRON in 2008 was also a big step, which propelled us into large-scale nanoparticle production. But the crowning vindication was the success of the field-scale verification of nanoparticle performance in groundwater treatment technologies and the positive comments about our nanoparticle products by independent users (Czech water-treatment companies, foreign universities and companies).”

Project case study

Following pilot-scale projects in 2012 an industrial site in the Czech Republic involved in producing various metal commodities since 1903 was chosen. A leakage of chlorinated solvents had occurred more than 20 years earlier (DCE, TCE and PCE) and the contamination had persisted in the groundwater up until the decontamination project started. The factory was built upon quaternary clastic sediments with the groundwater flow including the contamination plumes toward the river. The areas contamination level had reached 362 mg of chlorinated ethylene’s (ClE) per liter. Previous attempts at decontamination used venting, airsparging and stripping but this met with limited success and was ineffectual below the factory buildings.

The combined technology treatment consisted of three processes:

- Chemically assisted in-situ biodehalogenation using sodium lactate at a concentration of 80 g/l into the groundwater above the contaminated plumes and inclined to reach the contamination below factory buildings

- To prevent further contaminant migration and to protect the river; a diffuse permeable reactive barrier (DPR) was installed at three selected places. The iron particles used were commercially available air-stable nanoparticles NANOFER STAR (NANO IRON) and composite particles formed by the same type of nanoparticles and iron microparticles. The particle suspension was prepared on site and pumped into the groundwater below the factory buildings and roads

- An electric field with an intensity of about 1 V/cm was then applied across the diffuse permeable reactive barrier to enhance the effect of iron particles.

The sodium lactate caused a significant decrease of ClE concentration within the contamination plumes, and the ZVI composite/nZVI particles (in combination with an applied electric field) successfully stopped the migration of contamination flow. The concentration of ClE dropped quickly to 10% of the initial concentration. The DPR barrier has proved to be effective over the long-term (up until 2016) and the formation of additional toxic metabolites has not been observed.

Limitations

The main imitations of zero-valent iron nanoparticles for widespread adoption in water treatment include:

- Price and nanoparticle availability - (up to now, the production is in the order of a few tons per year and the price is relatively high for the treatment of millions of gallons of water per day)

- Society - the use of nanomaterials for purification in the environment is making people uneasy

- Technological limitations, including limited migration in groundwater conditions.

According to Dr Filip, there is little reported negative effect of iron nanoparticles on the environment. Iron nanoparticles are really only iron oxide particles aggregated into micron-sized particles and are chemically identical to the iron oxides naturally present in soils and sediments.

The Future

In 2016 RCATM began to coordinate a national project funded by the Ministry of the Interior of the Czech Republic for advanced nanotechnologies to minimise the impact of escaped hazardous chemical substances endangering populations.

Several proposals have already been prepared, e.g., a bilateral project with the Austrian Institute of Technology (AIT) and BOKU University in Vienna.

Dr Filip has a very definite vision of the future for RCATM: “I foresee the research and fast commercialisation of new types of iron-based nanomaterials in the form of nanocomposites (e.g., combination of reductive properties of zero-valent iron part, and sorption properties of the matrix) which would be a cheaper option and allow improved performance of iron nanoparticles. The nanoparticles will be combined with other physical fields (electric, magnetic) and/or with microbiology.”

This will never be a technology to treat millions of gallons of water per day to remove contamination. “The technology is designed to be applied in places with a special type of contamination where conventional technology cannot be applied,” Dr Filip explains.

The widespread economic application of nanomaterials for water treatment will rely on: improved migration of nanoparticles in groundwater conditions; improved selectivity towards key/persistent contaminants; improved reduction and sorption of contaminants on nanocomposites and improved longevity.

Radek Zbořil, general director of the Regional Centre of Advanced Technologies and Materials, adds: “Essentially, there is huge potential for utilisation of nanotechnologies in water treatment, as water pollution is fast growing in most countries worldwide. The application of cheap nanocomposites with multiple effects could be a future technology for drinking and wastewater treatment in poor countries where, for example, the presence of arsenic in drinking water can cause adverse health effects”.

Huw Kidwell is a freelance correspondent for WWi magazine.

More Water & WasteWater International Archives Issue Articles