A review in the Czech Republic revealed high ammonia concentrations in the raw water feed of a new treatment plant. A novel method using nitrification bacteria immobilised in a PVA carrier was chosen for biochemical oxidation.

By Mrakota Jan, Krhutkova Olga, Subrt Michal & Fejfar Ondrej

Nearly all of the drinking water supplied to population of the Czech Republic is sourced from public water supply systems. The presence of ammonia occurs in surface or underground water mainly due to contamination from agriculture (application of fertiliser, livestock farming), in populated areas from sewage, and sometimes also as a result of natural processes.

The removal of excessive levels of ammonia from underground or surface waters usually involves either chemical or physico-chemical process, such as chlorination, ion exchange or reverse osmosis. Another approach is biological nitrification, which occurs on filters, in a fluid biological reactor with attached-growth biomass on media, in biological aerated filters or treatment in an aquifer.

At Czech water utility company ASIO, each technological solution for the removal of ammonium ions is assessed comprehensively and with regard to chemical, physical and microbiological indicators. Based on the concentration of ammonium ions, the most effective and economically viable technology is then selected.

Based on a detailed situation review, which showed high ammonia concentrations, higher conductivity and a low concentration of nitrates in the raw water, the conventional method for ammonia removal (break-point chlorination) was not adopted in the Modrice water treatment plant (WTP). Instead, a novel method using pure cultures of nitrification bacteria immobilised in a PVA carrier was chosen for biochemical oxidation.

Chemical indicators

The Modrice WTP was proposed for a newly built logistics complex to deal with a high content of chemical indicators such as iron, manganese, ammonium ions and also selected microbiological indicators in groundwater from a nearby borehole.

The technology takes into account the limited space requirements and fluctuations in consumption of drinking water. The technological line of the water treatment plant Modrice was installed in March 2016, with the biocatalyst later supplied by LentiKat’s a.s.. The configuration of the provided groundwater treatment solution comprises:

- Accumulation - 3.5 m3 tank for flow equalization and temperature adjustment

- Filtration I - disc filter for the removal of mechanical impurities and particles bigger than 130 μm

- Iron and manganese removal - a set of two parallel filters [a mixture of filtration sand (75 %) and media Green sand (25 %)]

- Lentikats MBBR nitrification

- Filtration II - disc filter with a porosity of 130 μm for separating suspended solids that have escaped from the nitrification tank

- Disinfection - chlorination with a 5% solution of sodium hypochlorite (NaClO), the dosage is controlled by a diaphragm dosing pump based on the water flow through the pulse meter

- Depth filtration - particles from 10 to 130 μm are separated on filter cartridge Turbidex

- Dechlorinating filter - a set of two parallel filters filled with granular activated carbon (approx. 80%) and filtration sand (approx. 20%) for removal of high concentrations of free chlorine (0.5 - 1.0 mg/L) and adsorbable organic substances

- Prophylactic disinfection - dosage of disinfectant is adjusted to a final concentration of free chlorine at the hygienic limit (≤ 0,3 mg/L).

The volume of water in the accumulation is regulated by an electro valve, in the event a sufficient amount of treated water in the accumulation the electro valve is closed and the water flows through with a regulated bypass flow rate of 0.7 m3/hour).

Nitrification

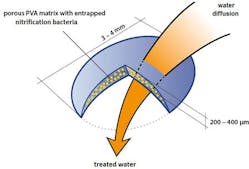

The supplied biotechnology is a MBBR-like technology and is based on the immobilisation of pure groups of microorganisms into porous PVA gel pellets, so-called Lentikats Biocatalysts.

The principle of Lentikats Biotechnology entails diffusion of contaminated wastewater through the pellet while entrapped bacteria convert/biodegrade the pollutants.

Immobilisation of pure strains of bacteria commonly present in nature ensures several fold higher concentration of microorganisms in the ammonia removal step. Higher biomass concentration (immobilised pure bacterial strains) compared to traditional technologies deliver significant advantages in the treatment process such as:

- Higher rates of nitrification

- Smaller reactor volumes

- Guaranteed removal efficiency

- Reduction in footprint thanks to shorter hydraulic retention times (hours)

- Minimum production of free bacteria leading to reduced demand for follow-up filters

- Higher operating stability against negative environmental effects (fluctuating influent concentrations pH, inhibiting effect, salinity, etc.),

- Easy/effective process control and guaranteed capacity of the system.

The nitrification process is carried out by autotrophic nitrification bacteria, using CO2 as the carbon source and ammonium as the energy source and consists of two steps - nitritation and nitratation - oxidation of ammonia ions via nitrites onto nitrates.

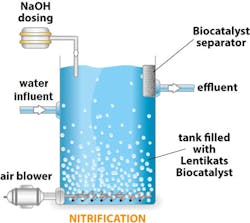

Lentikats nitrification uses pure AOB and NOB bacterial strains: Nitrosomonas europaea, Nitrobacter winogradskyi and Nitrospira spp immobilised in a PVA carrier. The treatment process is carried out in a separate tank where the PVA biocatalyst is kept in suspension with an aeration system. To retain the biocatalyst in the tank, a self-cleaning separator is normally placed before the water effluent pipeline. Treated water flows through a separation sieve while the biocatalyst remains inside the reactor. In this case, the biocatalyst separator is placed in the intermediate floor of the tank.

The continuous flow nitrification reactor is made of polypropylene (Fig. 2); the total volume is 6.2 m3 with a working volume of 4.2 m3. The tank is loaded with 275 kg of the nitrification biocatalyst, i.e. a 6.5 % load (w/w). The capacity of the tank (and the entire technology) is devised to accommodate a projected maximum flow of 2.5 m3/hr and influent concentrations of 12 mg/L of ammonia nitrogen.

The biocatalyst separator is a perforated stainless steel sheet with a mesh size of 1 mm placed 0.5 m above the bottom. Four fine-bubble aeration elements (discs) are fitted on top of the separator. Two probes for measuring dissolved oxygen concentrations, water temperature and pH and a hydrostatic probe for water level control are placed in the tank. Treated water is pumped using an automatic pressure station to the next stage of water treatment (filtration).

HRT in nitrification tank is maintained at approx. 3.5 hour, dissolved oxygen concentration around 9.5 mg/L and pH is maintained around 7.4. The hourly influent varies from 0.7 to 1.6 m3/hr and the water temperature from 11 to 17 °C depending on the season. Air supply is provided by a vane compressor with an output 12 m3/hr equipped with an air filter.

Raw underground water contains concentrations of ammonia nitrogen of approx. 5.8 mg N-NH4+/L (from 4.9 to 6.5 mg/L of N-NH4+) while the limit for drinking water is ≤ 1.0 mg N-NH4+/L.

Conclusions

After eight months of operation, is became clear that the day after biocatalyst loading, a concentration of - 0.6 mg N-NH4+/L (below the effluent limit) was obtained. The average effluent concentration was 0.22 N-NH4+ mg/L. The average volume N-NH4+ loading of the biological reactor (BV) was 0.041 g N-NH4+/m3/day while volume loading efficiency (ΔBV) was 0.039 g N-NH4+/m3/day. The overall achieved nitrification efficiency was greater than 96%.

After eight months of operation of the nitrification reactor with immobilised nitrification biomass at the water treatment plant Modrice, the reliability of the system was confirmed.

Moreover, there is no need for washing water as in the case of biofilm nitrification filters (back-wash procedure), no chemical addition and no threat of chemical leakage or corrosion as in the case of break-point chlorination.

System operation of the Lentikats nitrification reactor showed promising results and highlighted the potential of this biotechnology. Ammonia nitrogen removal was achieved with an average efficiency of 96.5%. Biological ammonium removal with immobilised nitrifiers is confirmed to be suitable for water treatment, especially for low-capacity solutions for water rich in ammonia.

Michal Subrt and Ondrej Fejfar are from water utility ASIO and Jan Mrakota & Olga Krhutkova are from technology supplier, LentiKat’s a.s.

More Water & WasteWater International Archives Issue Articles