By James H. Singleton and Douglas C. Timpe

On April 20, 2011, the Environmental Protection Agency (EPA) issued its proposed Phase II rule for implementing the requirements of Section 316(b) of the Clean Water Act (CWA). Section 316(b) and the proposed Phase II rule stipulate the use of Best Technology Available (BTA) in designing cooling water intake structures to reduce impacts to aquatic organisms. The EPA estimated that roughly 1,260 existing facilities will be regulated under the proposed Phase II rule, including about 590 manufacturers and approximately 670 power plants.

This paper compares issues and costs of implementing selected technologies outlined in the 2011 proposed Phase II rule at a reference plant. The reference plant selected for this evaluation was a power plant, but the concepts and technologies identified for water intake compliance are applicable to any type of facility.

Impacts of Concern

The impacts of greatest concern for cooling water intake structures are the entrainment and impingement of aquatic organisms. Entrainment occurs when fish and other organisms are drawn into a cooling water intake structure and pass through the cooling system. Impingement occurs when aquatic organisms are trapped against a screening device when water is drawn into the facility’s cooling system. Both can result in the injury or death of the affected organisms.

Requirements

- The proposed Phase II rule applies to an existing facility that meets the following criteria:

- Is an existing power generation, manufacturing or industrial facility;

- Withdraws water from waters of the United States, of which at least 25 percent is used for cooling;

- Is a point source as defined by EPA; and

- Has a total design intake flow exceeding 2 million gallons per day (MGD).

The proposed Phase II rule establishes the following BTA performance standards for existing cooling water intake structures (excluding new units at existing sites). The standards emphasize reducing the mortality of aquatic organisms caused by entrainment and impingement.

Entrainment Mortality (EM). The proposed Phase II rule does not prescribe specific EM standards for existing facilities but calls for such standards to be established on a case-by-case basis. However, existing facilities may choose to comply with the following EM standards established for new units at existing facilities.

- Reducing average intake flow (AIF) – Facility must reduce its AIF to a level commensurate with a closed-cycle recirculating system.

- Employing technologies to reduce EM – The facility may employ other technologies to reduce EM.

Impingement Mortality (IM). The proposed IM performance standards for existing facilities include: (1) meeting annual and monthly numeric IM standards; or (2) meeting an intake velocity standard.

- Numeric IM standards:

- Monthly IM: 31 percent or less.

- Average annual IM: 12 percent or less

- Intake velocity: 0.5 foot per second (ft/sec) or less, where the maximum flow velocity is either the maximum actual or maximum design intake velocity.

- Additional requirements:

- Facilities using marine waters must also reduce shellfish IM to a level comparable to barrier nets.

The proposed Phase II rule identified the following technologies that are considered BTA for meeting the performance standards described above.

Entrainment Controls

- BTA developed on a case-by-case basis.

- Cooling towers and fine mesh screens (2 mm or smaller mesh) are considered as potential EM control technologies.

Impingement Controls

- Traveling screens with collection buckets; guardrails to prevent loss of fish from buckets; smooth woven screen panels; a low-pressure wash to remove fish prior to any high-pressure debris spray; and a fish handling and return system.

- For marine environments, barrier nets or technologies capable of reducing shellfish IM to a level comparable to barrier nets (i.e., cylindrical wedgewire screens, dual-flow screens and drum screens).

- The rule does not appear to preclude the use of other technologies in meeting the IM performance standard.

Reference Plant

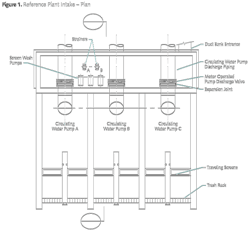

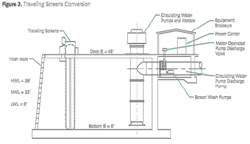

For this analysis, a “reference plant” was used to represent the typical configurations and operating modes that could influence the cooling water intake system. The “reference plant” was assumed to be a 600 MW power plant with a 530 mgd (design capacity) once-through cooling system. The water source is a navigable, freshwater river. The plant has three circulating water pumps. At normal river elevation, two pumps supply the required flow; at low river elevation, three pumps are required. The plant uses standard through-flow traveling water screens with two screens for each pump cell (Figures 1 and 2). The through-screen velocity at full load is 2.0 ft/sec at normal river level and 2.5 ft/sec at low river level. The screen mesh is 3/8 inch.

Selected Compliance Options

A number of technologies are available for reducing EM and IM. However, the following technologies were selected for evaluation based on their effectiveness in addressing entrainment and impingement, their potential for meeting BTA performance standards, and their anticipated favorable review by agencies:

1. Upgrade Existing Traveling Water Screens. The existing through-flow traveling screens would be replaced with new through-flow screens, “fish-friendly” construction features, a fish collection/return system and 2 mm mesh.

A variation of this approach would include replacement with dual-flow screens and the same fish protection features described above.

2. Reduce Intake Velocity. This would include reducing the intake velocity to 0.5 ft/sec and using 2 mm mesh screens for addressing entrainment. The intake could be enlarged and additional screens installed to reduce the intake velocity. However, this would require increasing the screen area by at least five times and involve major costs, which would not be feasible for most plants.

Alternatively, velocity reduction could be achieved by converting to cylindrical wedgewire screens. This would meet the IM BTA intake velocity standard by designing the screens for 0.5 ft/sec through-screen velocity, and 2 mm slots would address entrainment.

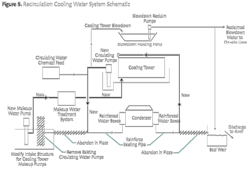

3. Convert Once-Through System to Closed Cooling System. This would use a closed circulating water system with a wet cooling tower to meet the IM BTA intake flow reduction standard and reduce entrainment by decreasing cooling water withdrawals from the river.

Key Features

The following paragraphs discuss the key features of each compliance option. Facility impacts, indicative costs, and advantages/disadvantages of each are summarized in Table 1. Familiarity of the reader with the technologies addressed here is assumed, so details are not included in this article.

Modification Option 1 - Replace Through-Flow Traveling Screens With Upgraded, “Fish-Friendly,” Through-Flow Traveling Screens

Modification of existing screens to a fish protection design may be possible. The extent of modification would include:

- Replacing screen sections.

- Adding pumps and piping for the fish spray system.

- Modifying and raising the head structure to accommodate the fish spray system piping and fish return troughs.

- Replacing the drive chain.

- Replacing the screen drive motor to accommodate power requirements of new screen drives.

- Adding a fish return system.

- Modifying the existing debris wash system and debris troughs.

It is generally more economical to replace the entire existing screen assembly with a new screen.

Modification Option 1A -Replace Existing Through-Flow Screens With Upgraded Dual-Flow Traveling Screens

Dual-flow screens are oriented parallel to the flow and may provide a larger screen face area than comparable through-flow screens. Theoretically, dual-flow screens with an effective flow area equivalent to five times the area of the existing screens could reduce through-screen velocity from 2.5 ft/sec to 0.5 ft/sec. However, as the dual-flow screen is increased in size along the axis parallel with the path of the incoming water flow, it becomes increasingly difficult to maintain even flow distribution over the screen surface. The feasible increase in length for a specific intake depends on many facility-specific factors.

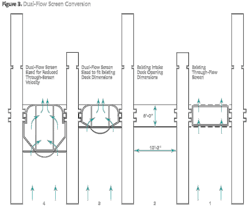

Screen manufacturers generally recommend two approaches for dual-flow screen conversions: (1) installing a dual-flow screen in the existing screen opening; or (2) replacing the existing screen with a larger dual-flow screen. The dual-flow screen replacement approaches are illustrated in Figure 3. Bay 1 (on the extreme right) shows the existing through-flow screen configuration. Bay 2 shows the size of the existing opening in the intake structure deck with the existing screen removed. Bay 3 shows a dual-flow conversion screen utilizing the existing opening in the deck. Bay 4 illustrates installation of a larger dual-flow screen to provide reduced intake velocity or smaller mesh openings without increasing the velocity.

Modification Option 2 - Conversion to Cylindrical Wedgewire Screens

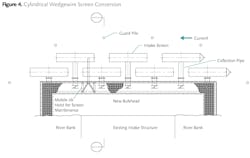

Wedgewire screens use a triangular cross-section wire material configured in a cylindrical shape. Wedgewire screens can be configured to limit intake velocity to 0.5 ft/sec or less while using small slot sizes for entrainment protection. Because of the very small screen openings, a large surface area is required to pass the quantity of water needed for a plant the size of the reference plant. Converting a facility’s existing intake would require installing several screen units to provide adequate open area for the required circulating water flow.

Wedgewire screens can be mounted on collector headers on the river bottom or on a bulkhead wall. This analysis assumed a bulkhead mounting configuration, which allows for better access for screen maintenance. A slide rail system was assumed for screen removal and onshore inspection and repair.

Modification Option 3 - Conversion to Closed-Cycle Cooling with Wet Cooling Tower

The proposed Phase II rule states that a facility may reduce its cooling water intake flow to that commensurate with a closed-cycle recirculating system. Such a conversion would have ongoing major operating, maintenance and power requirement impacts on an existing facility.

Conclusion

Overall, retrofitting screens with fish protection features and/or converting to dual-flow screens would be the most viable options for the reference plant.

If full compliance cannot be achieved with screen retrofits or conversions, wedgewire screens would be the next most viable option, although at higher costs and with additional permitting issues. Conversion to cooling towers would likely be the most readily accepted 316(b) compliance option but would be the least viable due to high capital costs and impact on plant output.

About the Authors: James H. Singleton is an engineering manager and senior mechanical engineer with Black & Veatch in Overland Park, KS. He has nearly 39 years experience in the power generation industry, encompassing design and construction of new facilities as well as retrofit and upgrade projects and studies for coal fired, simple cycle, combined cycle, integrated gasification combined cycle (IGCC), and hydroelectric power plants. Douglas C. Timpe is a project manager and technical lead in Black & Veatch Energy’s Environmental Services group in Overland Park. He has over 30 years of experience in environmental studies, environmental impact analyses, and regulatory review and compliance.