By William A. Shaw

As regulations and environmental sensitivity increase, many industrial plants are considering ways to reduce their water discharges. Zero liquid discharge (ZLD) processes are being studied in anticipation of even more restrictions on water discharges in the future. However, ZLD systems can be very expensive from both a capital and operational perspective and evaporators and crystallizers are often perceived as complicated and difficult to operate. New approaches to evaporator system design, especially low temperature evaporation, will provide additional options to those industries which are looking for methods to effectively and economically reduce or eliminate their water discharges.

In most industrial plants, the cooling system is responsible for the most water consumption and the largest water discharge. Historically, evaporation has been used very successfully to eliminate discharge of cooling tower blowdown, particularly in the power generation industry in the western U.S., where ZLD systems have long been employed mainly for water conservation purposes.

Since cooling tower blowdown is relatively dilute, generally less than 10,000 mg/L total dissolved solids (TDS), reverse osmosis membranes can often be applied to pre-concentrate the cooling tower blowdown prior to concentration in an evaporator and reduction to a solid in a crystallizer. The salts present in cooling water are typically mainly sodium sulfate and sodium chloride with small quantities of calcium and magnesium sulfate and bicarbonate. These are all salts which can be crystallized readily from solution by evaporation of water.

Many industrial facilities generate wastewaters which contain highly soluble salts, such as calcium and magnesium chlorides, sodium and ammonium nitrates, and certain salts of organic acids such as sodium formate, which are not so easy to crystallize out. These wastewaters include blowdown from FGD scrubbers in coal-fired power plants, grey water from coal gasification processes, shale gas frac and produced water, and landfill leachate. When considering eliminating discharge of these wastewaters, these facilities are frequently limited in the treatment options which will work as well as very high capital and operating expenses.

Low temperature evaporation provides a novel approach to achieve environmental goals while maintaining or lowering operating costs and reducing capital costs when compared to current ZLD options for highly soluble salt solutions.

In 2009, HPD, a Veolia Water Solutions company, introduced a new ZLD process called the CoLD™ process (Crystallization of High Solubility Salts at Low Temperature and Deep Vacuum). The CoLD Process was developed based on long-established crystallization techniques used in the salt, chemical, and fertilizer industries. It is now being applied in power plant wastewater treatment and recycle to achieve zero liquid discharge for some difficult waste streams.

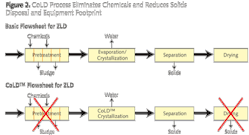

The process uses a vacuum crystallization step operated at low temperature. The chemistries of many wastewaters favor the formation of hydrates and double salts which precipitate at lower concentrations as the temperature of the solution is lowered. The boiling point elevation of solutions is also less under vacuum conditions. The advantage of the CoLD process is that the low process temperature eliminates the need to soften, chemically condition, or pre-treat the feed brine to the ZLD process.

Elimination of the pretreatment avoids solids settling and filtration equipment, sludge dewatering equipment, and chemical feed/storage facilities, substantially reducing the footprint of the overall wastewater treatment plant. It also avoids extensive sludge production with resulting costs for dewatering and landfill disposal and reduces the requirements for high alloy materials of construction usually required for a crystallizer train processing high chloride brine.

Energy and capital costs for the new process are comparable to current evaporation and crystallization technology, but there are huge savings in chemical and sludge disposal costs by eliminating the need for pretreatment.

The CoLD crystallization process is the only method which results in direct crystallization of highly soluble salts, including chlorides, nitrates, and salts of organic acids. It is a common process used in industrial salt crystallization, having been widely applied over the last half century in the production of such chemicals as sodium carbonate decahydrate from trona; sodium sulfate decahydrate (Glauber’s salt) for detergent use; chloride salts of calcium, magnesium, potassium, lithium, and ammonium from natural brine deposits; nitrate salts of ammonium, sodium, and strontium in the fertilizer and chemical industries; and salts of organic acids such as glyphosate, the main ingredient in the herbicide Roundup.

In the production of all of the above-mentioned salts, the final crystallization of the salt is done in vacuum crystallizers to take advantage of the reduced solubility and boiling point elevation of the desired salt at low processing temperature.

To understand the principle behind the crystallization, we will use the example of a ZLD wastewater treatment plant for FGD limestone scrubber purge. CoLD crystallization of purge streams from wet scrubbers can be accomplished using no chemicals and only electric power using a forced circulation crystallizer with a closed cycle heat pump and a solids dewatering device.

The FGD wastewater is mixed with the mother liquor discharged from the centrifuge and the mixture is introduced into the boiling chamber of the crystallizer. The raw feed and returned mother liquor mix with the recirculating brine in the crystallizer. Sufficient heat to boil the brine is supplied in the crystallizer forced circulation heat exchanger. The heated brine flows back to the boiling chamber, where it flash boils. As the solution concentrates by evaporation of water, crystals of solids which have supersaturated in the mother liquor grow inside the boiling chamber.

The evaporated water vapor flows into the condenser, where it gives up its latent heat and condenses. The condensate is extracted from the condenser by a pump and any non-condensable gases are extracted by the vacuum system. The concentrated slurry is pumped from the boiling chamber to a dewatering device such as a centrifuge or pressure filter, which separates the solids from the mother liquor which flows back to the crystallizer boiling chamber. The dewatered solids are collected for disposal.

The heat required to boil the liquid and the cooling necessary to condense the water vapor are supplied by a closed cycle heat pump. Several different refrigerants can be used as the working fluid in the heat pump including ammonia or hydrofluorocarbons. The refrigerant fluid is heated by compressing it in the refrigerant compressor. Electrical energy which drives the compressor motor provides the work that is the source of heat for the crystallizer.

Part of the heat imparted to the refrigerant by the compressor is transferred to the process liquor in the crystallizer heat exchanger by the partial condensation of the refrigerant. A water-cooled heat exchanger completes the condensation of the refrigerant and subcools it; the heat removed from the refrigerant is released to the environment. The liquid refrigerant flows through an expansion valve into the condenser, where it evaporates by heat which is transferred from condensing water vapor from the crystallizer. The cycle is closed as the refrigerant flows back to the compressor.

The advantage of CoLD crystallization is that the chemistries of FGD wastewaters favor the formation of many hydrates and double salts which precipitate at lower concentrations as the temperature of the solution is lowered. By operating the crystallizer under a high vacuum at a low operating temperature, a mixture of crystals of hydrated and double salts can be grown in the crystallizer and separated in a centrifuge or other solids separation device. These hydrated and double salts grow relatively large making the separation of a cake with low residual moisture possible. The mother liquor is recycled to the crystallizer for further concentration and crystallization.

The wet cake thus produced can be disposed of as is, and does not need further drying. Examples of some of the salts which can be crystallized at low temperature from FGD wastewater include the double salts tachyhydrite (CaCl2•2MgCl2•12H2O) and carnallite (MgCl2•KCl•6H2O) and the hydrated salts bischoffite (MgCl2•6H2O) and calcium chloride dihydrate (CaCl2•2H2O).

Besides the simplified flow scheme, the CoLD crystallization process results in substantial savings in CAPEX and OPEX, because eliminating the chemical softening step eliminates the cost of buying, shipping, storing, and handling of bulk reagents and also eliminates the dewatering, storage, transport, and disposal of the softener sludge.

The crystallization process will treat any wastewater containing significant quantities of high solubility salts. These waste streams can be evaporated to form stable solids using a closed cycle heat pump or other means to achieve a low boiling temperature in the crystallizer; thus,

- dispensing with the need to use chemicals to soften or otherwise condition the feed prior to evaporation;

- limiting the amount of solid to be disposed of to only that contained in the feed;

- discharging the final solid product as a wet cake, not requiring any further drying in order to transport or dispose;

- recovering all the water contained in the feed at a good quality, except for that left in the wet cake;

- requiring no energy source other than electricity;

- having a smaller equipment footprint.

About the Author: William A. Shaw, P.E., is a senior process engineer for HPD, a Veolia Water Solutions & Technologies company based in Plainfield, Ill. He may be contacted at [email protected].