By Jeffrey F. Kramer

Electric utility plants are large users of water for process cooling. A variety of cooling system options are possible including once-through systems, cooling towers or cooling ponds and are unique to each plant. Where large volumes of water are not readily available, cooling towers and/or cooling ponds are commonly used since their water turnover rate is low compared to once-through systems.

While cooling towers and ponds conserve resources, the presence of warm, nutrient rich water complete with ample sunlight means that they offer an ideal environment for microbial growth such as algae and bacteria. Algae are a particular concern in these systems since their growth produces copious amounts of biomass which can foul filters and screens. In addition, algae have been shown to provide nutrients for and stimulate the growth of bacteria.1

In order to control microbial growth in these systems, oxidizing biocides such as chlorine and bromine are commonly used. Algae exert a high demand for oxidizing which makes overall microbiological control more difficult. Because of this, supplemental biocides typically need to be used to control algae. Many of the common biocides used in industrial cooling systems are inappropriate in electric utility plants due to high dosage rates, foaming or environmental issues. One specialty algaecide, terbuthylazine, overcomes these limitations and has been particularly effective in controlling algae fouling in utility cooling towers and ponds.

Terbuthylazine and Algae Control

Unlike the biocides commonly used in cooling systems which are non-selective and thus target all microbes, terbuthylazine selectively controls the growth of all algae by inhibiting photosynthesis. Bacteria and other microbes are unaffected because they do not rely on photosynthesis for growth. Photosynthesis is a process of light-induced electron transport, whereby light energy is trapped in a chlorophyll-based pigment system and converted to chemical energy. This energy is then used at a later stage for the fixation of carbon dioxide, which provided a carbon source (sugars) for the growth of algae. Terbuthylazine inhibits the photo-oxidation of water which is the first step in this process.

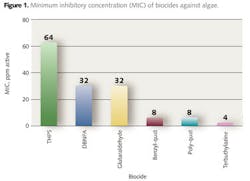

In addition to its specificity, terbuthylazine also effectively controls algae at lower dosages than other common industrial biocides (see Figure 1). Terbuthylazine is twice as effective as quaternary ammonium-based biocides (quat) and eight times as effective as glutaraldehyde or DBNPA on a ppm active basis in inhibiting the growth of algae. While quats appear to be relatively effective against algae, they have other drawbacks which limit their applicability. Studies have shown that benzyl-quats generate high levels of stable foam in use and, while non-foaming, poly-quats can inactivate anionic polymers used for scale inhibition.2 The same study showed that terbuthylazine was non-foaming and compatible with anionic polymers.

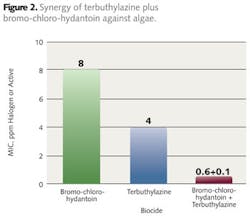

Since terbuthylazine has only algicidal activity, it is always used in conjunction with another biocide as part of a total microbial control program. One combination that is especially effective is the use of terbuthylazine with oxidizing biocides such as chlorine and bromine. The synergistic effect against algae seen with this type of combination allows for significantly lower levels of each biocide to be used. Figure 2 shows the synergistic effect of terbuthylazine with the oxidizing biocide bromo-chloro-hydantoin against algae. The synergistic effect is also seen with chlorine.2,3

Case Histories

Over the years, terbuthylazine has been used in combination with a wide variety of oxidizing and non-oxidizing biocides in actual cooling systems. These terbuthylazine/biocide combinations have shown exceptional ability to remove and control the re-growth of algae.4 The following case histories demonstrate the performance of terbuthylazine in actual cooling systems.

Case History 1

Chemical Plant Cooling Tower, Southeastern USA

System Parameters

Volume- 780,000 gallons

Recirculation rate- 35,000 gpm

Half-life- 4 days

ΔT- 20°F

Cycles- 7

pH- 7.8

Previous Treatment

The biocide treatment program consisted of a continuous free halogen residual of 0.5 ppm as chlorine plus a tributyl tin oxide containing non-oxidizing biocide. Despite this comprehensive treatment program, the system experienced a buildup of algae on the tower deck and structural support members during the summer months.

New Treatment and Results

The feed of bromo-chloro-hydantoin was maintained as before but the tributyl tin oxide containing biocide was replaced by terbuthylazine. The terbuthylazine was dosed at 3 ppm active three times per week. After only two weeks of treatment, 90-95% of the deck area was free of algae. Based on the excellent results obtained after two weeks, the frequency of terbuthylazine addition was reduced to twice per month. This program maintained the tower deck, fill and structural support members free of algae throughout the summer months and eliminated the need for the periodic physical cleaning previously required.

Case History 2

Foundry / Specialty Metals Plant Cooling Pond, Midwestern USA

System Parameters Volume- 3,000,000 gallons

Half-life- 51 days

Cycles- 1.4

pH- 7.5

The system consisted of four interconnected rubber-lined earthen ponds. Water depths vary from 6.5-7.5 feet. Figure 3 shows the configuration of the cooling pond system.

Water flows sequentially from Pond #1 to Pond #4. Water from Pond #4 is pumped throughout the site to various manufacturing buildings and three lift stations return the cooling water to Pond #1. A portion of Pond #4 water is discharged to a creek leading to a fifth pond prior to discharge off-site. Makeup is well water.

Previous Treatment

Microbial control of the pond cooling waters had previously been achieved through the application of sodium hypochlorite supplemented with periodic additions of a diquaternary herbicide to aid in the control of pond algae and aquatic plants. The high chlorine levels required for algae control resulted in trace levels of chlorinated organics in the system effluent so the use of sodium hypochlorite was discontinued.

In 2011, the treatment program was changed to hydrogen peroxide with periodic additions of the diquaternary herbicide. While this treatment suppressed the levels of bacteria and fungi, it was ineffective in controlling summer algae blooms in the ponds. The high algae levels in the ponds would foul the recirculating water strainers necessitating frequent disassembly and cleaning which resulted in plant shut downs and loss of production.

New Treatment and Results

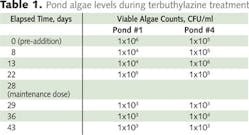

The diquaternary herbicide treatment was replaced by terbuthylazine for the 2012 algae season. The terbuthylazine was initially dosed into Pond #1 at 6 ppm active in early May with subsequent dosages of 3 ppm active every four weeks. The performance of the treatment was assessed visually by noting water clarity, and the amount of floating and submerged algae biomass. In addition to the visual assessment, viable algae levels in water from Pond #1 and Pond #4 were determined overtime (see Table 1).

Viable algae levels in Pond #1 were reduce by two orders of magnitude within 8 days after the initial dose of terbuthylazine and remained below pre-addition levels for three weeks. A further decline in viable algae levels in Pond #1 was noted after the application of the maintenance dose of terbuthylazine in week four and remained low for at least three weeks. Viable algae levels in Pond #4 did not decline until after the application of the terbuthylazine maintenance dose. Since the terbuthylazine was being added only to Pond #1, it appears to have taken time for an effective concentration to build up in pond #4 as treated water flowed sequentially from Pond #1 to Pond #4.

Water clarity improved over time in the ponds and the system was not plagued with floating masses of algae as in previous years (see Figure 4). The lower algae levels in the system resulted in less maintenance of the recirculating water strainers. Plant personnel were very pleased with the appearance of the ponds and the reduced maintenance required due to the new treatment.

Summary

The laboratory and field studies confirm that terbuthylazine is highly effective at controlling the growth of algae. It has advantages over other cooling water biocides commonly used for the control of algae such as effectiveness at high pH and hardness levels, non-foaming properties, and compatibility with anionic scale and deposit control additives. Terbuthylazine is synergistic with chlorine- and bromine-based biocides which reduces the overall amount of biocide necessary to control algae when this combination is used.

Acknowledgements:

The author would like to thank Dr. Peter E. Greenlimb of Chemagineering Corp., Rolling Meadows, IL, for his assistance in conducting the cooling pond case history at the foundry / specialty metals plant.

References

1. Pope, D.H., R.J. Soracco, H.K. Gill and C.B. Fliermans, Current Microbiology, 7:319-322 (1982)

2. Kramer, J.F., International Water Conference, IWC-95-47 (1995)

3. Gaffney, T.W. and C.L. Wiatr, Corrosion 98, Paper No. 525 (1998)

4. Smith, A.L., R.A. Muia and M.O. Clancy, Cooling Tower Institute, TP 88-15 (1988)

About the Author: Jeffrey F. Kramer, PhD, is Technology Manager for Biocides at BWA Water Additives where he's involved in new product development and applications research. He has over 20 years of experience in the use of biocides to control microbiological problems in industrial water systems. Kramer has published several papers on biocide topics and has been a frequent presenter at the Association of Water Technologies annual meetings, the International Water Conference, and the National Association of Corrosion Engineers conferences.