By Art Haddaway, WaterWorld Editor

Many industrial processes rely heavily on the use of water for much of their operations. Used for everything from producing steam to cooling various systems to maintaining overall machinery, water serves as a precious commodity that manufacturing facilities can't afford to be without, and the food and beverage industry is certainly no exception.

A highly water-intensive sector, food and beverage manufacturing -- whether pertaining to production or distribution -- uses large quantities of water for a variety of important purposes, such as storage, ingredients, boiling and chilling, equipment cleaning, and conditioning and transportation of raw materials. In fact, these processing plants can commonly use more water than almost any other resource to ensure that their facilities function properly.

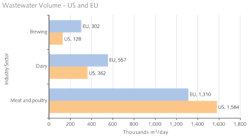

According to Aoife Moloney, senior research analyst at BlueTech Research, statistics from a model designed by BlueTech that calculates the volumes of wastewater derived from different industries indicate that the food and beverage sector -- specifically dairy, brewing, and meat and poultry -- produces roughly 2.07 million m3/d (547 million gallons per day, or MGD) and 2.17 million m3/d (573 MGD) of wastewater in regions of the U.S. and Europe respectively (see Figure).

With the massive amounts of wastewater generated by these facilities come a number of challenges, including "vast quantities of water use, wastewater treatment and sludge disposal costs, and high-energy consumption," said Moloney. "In terms of water recovery and reuse in the food and beverage industry, the fear of emerging contaminants in product water, water conservation commitments, increasing environmental standards, and corporate social responsibilities are driving the water reuse market."

When it comes to properly allocating water usage and effectively managing its effluent, food and beverage processes will benefit from conservation and treatment solutions that are cost-effective, energy-efficient and environmentally friendly. Further, improving these efforts is critical to reducing high water consumption, preventing pollution into local waterbodies and preserving the health of the public and surrounding wildlife.

In a recent report, the Food Manufacturing Coalition for Innovation and Technology Transfer (FMCITT) said it is imperative that the food and beverage industry seek effective reduction and recycling techniques for processing wastewaters. "These technologies include both source reduction options (technologies to reduce the amount of water used) and treatment options (technologies to reduce the amount or contamination level of wastewaters requiring discharge)," it noted.

Given the extent to which water is used within manufacturing facilities, conservation is a vital component, and reducing heavy reliance on water helps manufacturing operations minimize their overall water footprint and strengthen their ability to reach short- and long-term sustainability goals.

"Everything in the facility consumes water. When you look at the challenges that the industry is facing, no matter where they are, it's probably in areas that have water scarcity issues," said Melissa Meeker, executive director of the WateReuse Association. "If a facility is in an area where it already has stressed traditional water sources, additional water consumption is only going to add pressure. As a result, the facility will be pushed by regulatory agencies to look for creative ways to conserve water."

According to the FMCITT study, there are many water-savings techniques that facilities can consider, such as air-based transporting, low or no-water cooking and processing, and integrated reuse methods such as heat and byproduct recovery. It also identifies other methods that include implementing clean-in-place (CIP) systems, replacing conveyors with mechanical auger systems, installing spill collection trays at key production points that accumulate solids, and modifying production procedures to minimize overall wastage, among others.

Improving operations and maintenance (O&M) programs is also important for pinpointing problems and avoiding malfunctions early in the process that are responsible for higher waste and water usage, the report indicated. Improvements might include process-control-related techniques comprising advanced sensors and algorithms as well as modeling technologies that can help manage flow, temperature, chemical concentration, and more.

"One of the first things we need to do is identify critical control points where water is consumed, like wash down water or in cooling towers, and for each of those uses, determine the quality of water that's actually needed," said Meeker. "The goal would be to treat other on-site (waste) water to a certain level which is safe (conducive) for the use, allowing us to substitute a traditional potable source of water with a more sustainable reuse option."

Companies such as MillerCoors and Coca-Cola, for example, have implemented successful water stewardship campaigns utilizing advanced water reuse techniques that have significantly helped minimize ongoing water consumption within their facilities. Moloney explained that these businesses "have begun to develop sustainability plans and environmental targets that include reducing the product water usage ratio (water used/unit of product), improving efficiencies and reducing water usage.

"Environmental and sustainable performance metrics are becoming increasingly important for industries to meet in order to maintain their corporate social responsibility targets," he said. "These targets are driving the companies to commit to reducing their impact on the environment in terms of reducing their carbon footprint, emissions and water use, while increasing water reuse and energy and nutrient recovery onsite."

Data from the FMCITT report also showed that wastewater generated from food and beverage processes is distinct from other industrial activities, in that it generally does not contain conventional toxic chemicals, such as those listed under EPA's Toxic Release Inventory, but it can be subject to bacterial contamination, which represents a special issue for wastewater reuse, for example. Whether it is in fact recycled on-site or instead released into local waterbodies, the management of this wastewater requires special attention.

It is important to treat this effluent to prevent or eliminate harsh impurities before being apportioned, but the study also indicated that it can often contain high concentrations of elements that include dissolved or total suspended solids (TSS); biological oxygen demand (BOD) and chemical oxygen demand (COD); fats, oils and grease (FOG); and nutrients consisting of ammonia, minerals (e.g., salts), nitrogen, and phosphorus, to name a few.

These and other common contaminants can present difficulties for facilities that use traditional primary treatment methods and can potentially pose a threat to aquatic life, public health and the surrounding environment if not handled properly. As discussed in an article by Dr. Miroslav Colic, research director for Clean Water Technology, Inc., adopting new primary and secondary treatment methods is necessary to achieve success in this area.

Colic explained that sedimentation is an ideal approach that focuses on gravity separation for contaminants, with flotation being "a much more suitable technique to remove oil and particles with low density from water during or after de-emulsification," he said. The article showed that this includes induced and dissolved air flotation systems, along with centrifugal, jet and cavitation systems, based on certain factors like the state of the atmospheric solubility or amount or condition of these constituents. Further, moving bed biofilm reactors (MBBR) serve as one example of a secondary treatment option for the removal of wastewater sludge and pollutants.

Treatment through sterilization, membrane separation and concentration, conversion, retention and redirection, and biological methods are also at the forefront of treating industrial food and beverage process wastewater, as noted in the FMCITT report, in that they optimize the opportunities to successfully repurpose this effluent for the betterment of the facility. "Because water is ubiquitous throughout food processing plants, in-plant treatment of wastewater as a means of permitting reuse in other parts of the plant is a key strategy," the study suggested.

Moloney added, "We have identified potential future opportunities for anaerobic membrane bioreactors (AnMBR), polyhydroxyalkanoate (PHA) production, bioelectrochemical technology, and electro-methanogenisis, particularly as technologies that can provide effective solutions for industries and industrial wastewater treatment. These technologies aim to increase water reuse onsite, reduce the quantity of sludge produced and thus diminish the operational and sludge disposal costs, decrease energy consumption and increase nutrient removal and recovery."

Ultimately, there are a variety of internal and external factors that steer how these source-reduction and treatment techniques are used, as each facility is different and can have varying water and energy demands. Colic noted that the characteristics of wastewater can sometimes be represented through "a) large seasonal variation, b) large hourly variation in concentration and type of contaminants, c) often small and variable flows per day, d) colored effluent, and e) unbalanced concentrations of carbon, nitrogen and phosphorus, which complicates bioreactor treatment."

Meeker added, "Water is a local issue, and depending on where facilities are, they'll have greater challenges or lesser challenges, so I don't think you'll see a company institute the same changes in every location." It essentially comes down to facilities calculating and predicting their operating and disposal costs as well as determining the return on investment of these programs and technologies.