By Tom Daugherty

Most hydraulic fractured water (i.e., flowback and produced water) impoundments use air in some sort of treatment scheme. Many observers maintain that it is intuitive to inject air into a lifeless body of water. Evaporation of water is the primary management objective of many flowback impoundments and site management endeavors to increase the same. Various aeration schemes systematically churn water because it is widely believed that doing so promotes evaporation. Deployed irrigation systems are generally pumped waterfalls that flow back into the impoundment. In addition to supporting evaporation, this article will examine the quantifiable benefits of advanced aeration as a water treatment method.

Baseline: The Cycle of Water

The water we have on earth is all we have; new water is not created over time. The hydrologic cycle explains the circuitous route that water takes: Water is consumed, transpired or evaporated and then returns as precipitation or groundwater to repeat the cycle. Initially clean prior to use or consumption, water is simply a transport mechanism in municipal water treatment. Reclamation facilities exist to return the water to its natural state so it can be discharged to a local waterbody. And the water cycle continues.

Dissolved Oxygen

By merely observing water, one cannot detect the presence of oxygen -- other than the hydrogen and oxygen molecules. But the oxygen molecule is not what improves water quality and allows aquatic biota to survive. Dissolved oxygen (DO) must be present in ample concentration to support robust water health and is widely understood as a powerful oxidant. Even a stagnant pond can be brought back to life by effectively infusing DO into the water. In nature, a mountain stream cascading over rocks enriches the DO level, ensuring the survival of trophy fish species. Healthy DO levels promote beneficial biologic activity from naturally occurring microbes, and increasing DO in centralized impoundments initiates a plethora of water quality improvements.

Evaporation

Many centralized treatment ponds are also known as evaporative ponds, or pits. Two key components to natural evaporation in a water impoundment are heat (from sunlight) and surface air movement (from wind). Other factors include altitude, vapor pressure at the water surface, and vapor pressure of the surrounding air.1 One can discover myriad evaporation formulas based on geography, latitude, climate, and others, but the aforementioned factors are in play whether in the Permian Basin, Marcellus Shale or elsewhere. Interviews with three different evaporation pit operators revealed that none used scientific methodology to determine evaporation rate but all were confident that their aeration methods worked.

Advanced Aeration Improves Evaporation

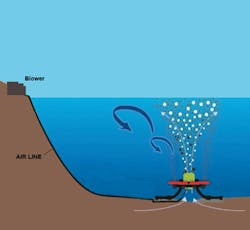

Multiple phenomena occur when fine and coarse bubbles are introduced beneath the surface in a water impoundment. First, the rising bubbles cause surface disruption and may add momentum to the air, increasing the rate at which the humid air is removed from the surface -- a critical aid to evaporation.2 Second, when air is introduced into water, bubbles are formed, and diffusing vapor in the water migrates to the interior of the bubble.3 The resulting migrant vapor in the bubble reaches 100-percent relative humidity and is released during the breakup process at the surface.4 The combination of fine and coarse bubbles delivered from the water-pit floor -- which effectively oxygenates and de-stratifies the entire water column -- is considered advanced aeration.

As mentioned earlier, a casual observation of existing fractured water impoundments notes some sort of surface aeration, weeping systems, periodic air jamming, or other air sparging. By field practice, operators are realizing the advantages of utilizing air in water management.

Score Card for Aeration Efficiency

In 1984, the American Society of Civil Engineers adopted aeration efficiency standards. The Standard Oxygen Transfer Efficiency (SOTE) test was developed to put all vendors/methods on an even playing field. The key to SOTE is evaluating the efficiency of introducing oxygen into a body of water, with bubble size being the single biggest factor. The trial is recorded at sea level in clean water at 20°C. Fine bubbles (< 1/8") tend to rise more slowly, providing better oxygen transfer efficiency, but coarse bubbles (>1/4" and often 1"-2") are more effective at mixing.

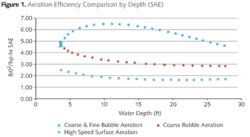

Other factors in analyzing an aeration system are flow rate, depth, temperature, elevation, layout, alpha and beta factors, and maintenance. Figure 1 examines Standard Aeration Efficiency (SAE) for various aeration types at different water depths. Note that the higher SAE rating is preferred, as it accounts for implied utility costs. The measurement is pounds of oxygen per horsepower per hour, expressed as "lbs-O2/HP-hr."

Nature's Oxidant

When advanced aeration is introduced to an impoundment, many water quality parameters begin improving in correlation to residence time or exposure. Fine bubbles can effectively introduce DO into the target waterbody. Assuming anaerobic conditions, a transformation from anaerobic (DO < 1.0 mg/L) to aerobic (DO > 1.0 mg/L) water occurs. Sulfate reducing bacteria (SRB) are susceptible to the oxidation potential of DO.5 Initiating the oxidation of SRB inhibits the formation of hydrogen sulfide, a colorless gas that is corrosive, poisonous, flammable, and explosive. Effective infusion of DO also initiates hydrogen sulfide oxidation, which helps mitigate multiple issues, including odor.6 With increased DO, the pH level in the waterbody begins to stabilize. This is valuable considering that a target pH value between 7.0 and 8.0 is optimum for maximum hydrogen sulfide removal.7 The waterbody also begins stripping CO2, light hydrocarbon gases and VOCs due to redox, which is a reflection of its oxidative and reductive capacity.

DO transforms metals such as iron and manganese to their oxidized state. This allows them to be filtered out or settled to the bottom of the pit. Guar residues and other organics also begin oxidizing, which fosters increased light transmissivity or clarity to the water. The surface disruption caused by advanced aeration also reduces surface matting and encrustable formations. This benefit is twofold, as it allows deeper access to the waterbody by ultraviolet rays and provides a naturally corralled surface area for potential skim harvesting of migrant hydrocarbons. These documented water quality improvements offer contaminant load reduction for downhole reuse or follow-on treatment trains such as electrocoagulation, reverse osmosis and others.

Anaerobic water pits cause certain treatment chemicals to be oxidized or partially consumed. The "serendipitous uptake" by non-target contaminants wastes chemicals and money. This can cause the chemicals to be less effective, leading to costly over-dosing. Increasing DO with advanced aeration will optimize subsequent chemical use and increase operator control and understanding of water pit behavior.

Taking control of fractured water impoundments is a critical first step in subsequent treatment, recycling, evaporation, or other intended reclamation of the water. By addressing the water chemistry early in the process, costs are better controlled and processes are improved. A cursory observation of the literature coupled with the data presented in Figure 1 suggests that using pit-floor aeration deploying fine and coarse bubbles would offer multiple water quality benefits. Notwithstanding nuances from site to site, advanced aeration merits serious consideration in the continuum of fractured water management.

About the Author: Tom Daugherty has been involved in the environmental industry for the past 12 years as the former president of Blue Water Technologies and a firm engaged in water quality monitoring under Homeland Security Initiatives. He is currently a principal with Sustainable Organization, LLC, a management consulting firm specializing in sustainability. Daugherty holds an MBA in sustainability from Marylhurst University. He can be reached at [email protected].

References

1. Potts, D. Estimation of Evaporation from shallow ponds & impoundments in Montana. Misc pub #48. Montana Forest and Conservation Experiment Station. School of Forestry, University of Montana, 1988.

2. Brutsaert, W. Evaporation into the atmosphere. Dordrect, Reidel. 299pp, 1982.

3. Burkard. M.E. and Van Liew, H.D. Simulation of exchanges of multiple gases in bubbles in the body. Resp. Physiol., 95 (2). Pp 131-145, 1994.

4. Helfer, F., Lemckert, C., and Zhang, H. Influence of bubble plumes on evaporation from non-stratified waters. Journal of Hydrology. Volumes 438–439, pp 84–96, May 2012.

5. Characklis, L., and Lee, W. Review article on the influence of dissolved oxygen on sulfate-reducing bacteria related corrosion. Mycotoxins, Wood Decay, Plant Stress, Biocorrosion, and General Biodeterioration, Biodeterioration Research Volume 4, pp 519-526, 1994.

6. Sharma, K, and Yuan, K. Kinetics of chemical sulfide oxidation under high dissolved oxygen levels, 6th International Conference on Sewer Processes and Networks. Gold Coast, Australia, November 2010.

7. Chen, K., and Morris, J. Kinetics of aqueous sulfide by O2. Environ. Sci. Technol., 6 (6), pp 529–537, 1972.