Red Gold, Inc., located in Orestes, IN, approximately 45 miles north of Indianapolis, is the nation's largest privately held tomato processor. Although Red Gold processing facilities produce over 100 different styles of tomato products, the Orestes facility focuses on canning fresh tomatoes, such as whole peeled and diced tomato varieties. This brings a particularly unique seasonality to the process water generated by the facility and special challenges to its treatment.

By January of each year, the system is shut down and the operation is not resumed until May. The system has to begin discharging in June to the receiving stream. Obviously, this is a very short timeframe for building a bio-mass to sufficiently support the process water volumes of a large canning facility.

According to Mike Herrmann, Red Gold Director of Engineering, prior to 1999 the facility's National Pollution Discharge Elimination System (NPDES) permit parameters were limited to total pounds of BOD and total pounds of TSS discharged to the receiving stream, based on pounds per unit of stream flow.

At that time, Orestes' process water treatment facility consisted of six holding ponds: one for the collection of suspended solids, totaling 7 million gallons; one strictly for hydraulic detention, approximately 30 million gallons; two equipped with inefficient surface aerators, 10 million gallons; plus one polishing pond. Process water was accumulated in the 5 million gallon cells, and essentially batch-treated. The process was completed by testing the water prior to discharge.

The new proposed NPDES permit, for releases after 1999, established a limit on ammonia nitrogen (NH3), in addition to the previously established parameters associated with BOD and TSS. Parameters associated with BOD, TSS, and NH3 were limited to a fixed mg/l value and a limited total pounds of each to the receiving stream. Also, the existing detention basins did not contain the volume of water associated with planned production requirements.

"NH3 is not initially present in our process water," Herrmann said. "NH3 was determined to be the result of the organic decomposition in the anaerobic detention basins. The situation was further complicated by the fact that the year 2000 was exceptionally dry, which resulted in below average receiving stream flows.

"Fortunately, the Indiana Department of Environmental Management provided language in the new permit to allow for the phasing in of the new requirements over three years. In other words, they provided Red Gold with a three-year compliance period."

Package Treatment System

Red Gold's corporate management team—under the leadership of Brian Reichart, Owner and CEO, Dale Needleman, Vice President of Manu-facturing, Herrmann and Rachel Strock, Project Engineer, decided to take a proactive role, incorporating a state-of-the-art package treatment facility into the Orestes plant in six months, 2 1/2 years ahead of the requested Indiana Department of Environmental Management compliance period.

The appropriate BOD, TSS, NH3, FOG, and hydraulic capacity requirements had already been established

by Red Gold personnel. So, the only thing left to do was to distribute project information and requirements to potential equipment suppliers to establish an economic basis.

Red Gold considered alternatives that ranged from increased aeration in the detention basins to sequencing batch reactor technology, oxidation ditch technology, and complete mix extended aeration systems. After careful assessment, Red Gold selected USFilter's complete mix plug flow aeration treatment system, with internal clarifier.

"The Red Gold team was confident that USFilter could deliver the hardware prior to that year's harvest campaign, less than eight months from the time the purchase order was released," Herrmann said.

USFilter's team of fabricators and engineers in Thomasville, GA, had installed a system six years prior at a sister plant. Also, USFilter engineering specialists were familiar with Red Gold's process stream.

Application Details

According to Herrmann, "Facility process water can have TSS well above 20,000 mg/l when it leaves the cannery. Most of these solids drop out in the first 7 million gallon pond. The second anaerobic pond can contain as much as 30 million gallons. This pond acted as the primary clarifier as well as provided some facultative treatment — facultative in that the surface area is quite large. It was recognized that since no aeration was incorporated there would be a loading of NH3."

Consequently, the new system was designed to treat a flow of 500,000 gpd with a BOD of 2000 mg/l; TSS of 500 mg/l; TKN of 220 mg/l. The effluent of the new system is pumped to a surface water stream and meets requirements of 22 mg/l of BOD; 26 mg/l of TSS; and 4.5 mg/l of NH3.

Influent to the package treatment plant is pumped via a submersible pump to two anoxic zones at the head of the plant. Water from the anoxic zones flows equally into two aeration cells referred to as Aeration Zone One and Aeration Zone Two. The process water flow then combines and continues to be treated aerobically in two additional aeration zones referred to as Aeration Zone Three and Aeration Zone Four. The treatment of NH3 occurs in the last two zones and the treatment of BOD occurs in the first two zones.

Water from the fourth aeration zone flows into the clarifier. Return activated sludge is returned to the anoxic zone at the head of the plant. The anoxic zone is also referred to as the selector zone, since the undesirable organisms such as filamentous do not survive in undesirable populations in the absence of oxygen.

Performance Results

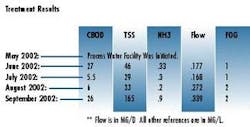

"Overall, the plant is performing well, with NH3 levels of 1 mg/l or less and BOD/TSS levels far less than those required to be compliant. Properly maintained and serviced, the system can dependently be expected to deliver good quality effluent that will meet and exceed all the quality parameters established by the Indiana Department of Environmental Management's expectations," Herrmann said.

"USFilter was willing to establish a partnership with us," he added.

For example, in order to control costs as well as to expedite the Red Gold schedule, USFilter assumed certain responsibilities such as supervising owner contracted labor. Based on the company's engineering, Red Gold was able to contract local labor to pour and finish concrete under the supervision of USFilter's field representative. Using local talent and skills under the direction of USFilter's project managers was a common practice. The same held true for the equipment room and its associated piping requirements."

"What makes the system unique is that it is operated on a seasonal basis," Herrmann said. "With a start-up on an annual basis, the bio-mass is constantly acclimating. The USFilter system has been successful in accomplishing this task, and we are all very pleased with the results."