North Salt Lake and West Bountiful, UT, are home to several large oil refineries. These large plants have smoke stacks, open burning flares, and round storage tanks. Speeding by on the highway, people probably imagine that these industrial companies are shamelessly polluting the environment. To the contrary, Silver Eagle Refinery proactively worked with the South Davis Sewer District and WesTech Engineering to find a treatment solution for environmental pollutants generated at its facility.

During the production of gasoline products, oil refineries generate a waste stream that contains petroleum by-products such as BTEX (Benzene, Toluene, Ethylbenzene, and Xylenes). These volatile, monoaromatic hydrocarbons can be toxic to receiving streams with different populations of organisms. Until recently, Silver Eagle had discharged these harmful compounds to the South Davis Sewer District North Plant.

At the wastewater plant, a trickling filter treatment process had been degrading these compounds biologically. But high levels of BTEX can upset the biological process and cause problems for a wastewater treatment plant. Silver Eagle Refinery and the South Davis Sewer District wanted to explore different methods of treating the BTEX before it was sent to the district's wastewater plant.

To prevent any upsets at the wastewater plant, the South Davis Sewer District decided to limit the Silver Eagle Refinery discharge of BTEX to 5 ppm. As the treatment plant had proved, specific organisms could be employed to biologically remove BTEX. With these tighter restrictions, the refinery started to evaluate a pre-treatment program for its waste. Silver Eagle joined with local process company, WesTech Engineering, to conduct a pilot study. The goal was to find a biological system that would significantly reduce the BTEX discharge to meet the limits required by South Davis.

Pilot Plant Equipment

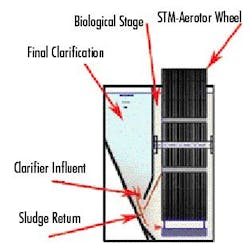

WesTech recommended its compact STM-Aerotor® Pilot Unit. It consists of a 10-foot-long, 6-foot-wide, and 8-foot-tall container unit including a biological stage and an integral settling clarifier. The two-stage tank has an inlet feed into the biological stage, an effluent pipe in the clarification stage, and a drain used for wasting sludge. A baffle wall separates these two areas.

The STM-Aerotor® wheel contains several rows of unique plastic media, a strong structural cage, center shaft, roller chain, and a low-horsepower drive unit. The plastic media has two main functions. First, its hollow interior captures atmospheric air, draws it down into the mixed liquor and releases it for aeration. Second, the media provides a large surface area for the growth of fixed film organisms.

The steel cage supports the rows of plastic media. Submerged up to 80%, the wheel relies on buoyant force to support a portion of its weight. The drive rotates the wheel with a single 1 HP motor via a steel roller chain.

Process Objective

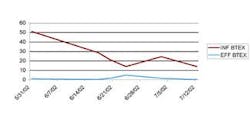

The Silver Eagle Refinery wanted to meet the 5 ppm BTEX limit on its discharge without building a large treatment facility that required extensive operations and maintenance. The refinery has a holding tank that discharges a BTEX waste stream that varies from 60 to 15 ppm. WesTech provided the STM-Aerotor® pilot plant to receive a small portion of this waste stream to determine if the technology would effectively treat the BTEX. The chart below provides a summary of the influent and effluent characteristics for the pilot plant.

The organisms in the pilot plant tank successfully oxidized the influent BTEX, meeting the 5 ppm limit. During the study, the influent BTEX varied considerably, but the effluent BTEX remained around 1 ppm. During a stress test, the pilot unit received flow rates well above its design. Even during these high flows, the pilot plant removed the BTEX below the 5 ppm limit.

Pilot Plant Data - Silver Eagle Refinery

After the pilot test, the Silver Eagle Refinery decided to install a full-scale STM-Aerotor® plant to treat its effluent. The full-scale plant has been operational since January 31, 2003. Currently, Silver Eagle operates the plant without a settling clarifier. Therefore, the treatment mainly comes from the fixed film organisms instead of a suspended growth population of organisms. In the future, Silver Eagle plans to add a settling clarifier so that a portion of the suspended growth organisms can be recycled from the clarifier back to the STM-Aerotor basin.

The South Davis Sewer District has been sampling the effluent of the new pre-treatment plant. So far, Lyndon Tan of South Davis reports that the refinery has met the 5 ppm limit during every test. Silver Eagle Refinery Operations Manager Gil Higham enjoys the ease of operation and lack of extensive maintenance. When asked about routine maintenance, Higham reported that staff need only clean the dissolved oxygen probe once per week because of the biological growth in the basin.