By John A. Meidl and Jerry M. Ramdhani

Biological wastewater treatment systems (biosystems) may experience in-plant toxicity when excessive amounts of oil, grease and/or difficult-to-treat contaminants escape the primary system or spent caustics are not adequately treated.

For petrochemical/chemical plants, whole effluent toxicity of water-dwelling fish and animals is one of the biggest toxicity worries. The biosystems at such plants may perform poorly, or may be incapable of entirely removing certain organics, ammonia, metals and dissolved solids. Such system inadequacies can impede the plant's ability to pass an effluent bioassay test.

Bioassay problems are commonly addressed using activated carbon. Highly porous and with a surface area typically greater than 950 square meters (10,226 ft2) per gram, activated carbon removes contaminants from water when they are adsorbed on the carbon's surface. Many factors influence this adsorption process and determine how much carbon will be required for a particular application.

These factors include characteristics of the activated carbon (surface area, pore volume, particle size), the contaminants (water solubility, molecular size, polarity) and the stream being treated (flow rate, dissolved solids, competing constituents).

Activated carbon may be applied in either powdered or granular form. The former actually converts the biosystem to a powdered activated carbon (PAC) system; the latter uses filtration plus adsorption after the biosystem to reduce water toxicity.

PAC treatment

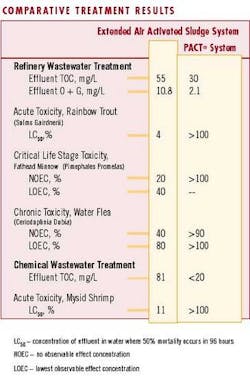

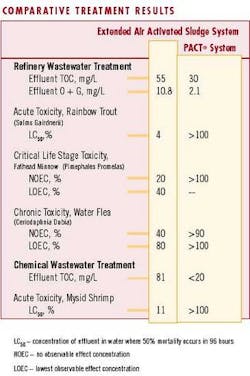

By converting a biological process to a combined powdered carbon/biological process, such as in USFilter's Powdered Activated Carbon Treatment (PACT®) system, the upgraded process is able to remove toxics or inhibitory substances more efficiently and effectively than by using biological treatment alone.

Organics are adsorbed on the carbon surfaces and are exposed to biological treatment for the system's solids residence rather than merely the hydraulic detention time as would occur in a conventional biosystem.

The PACT® system further enhances removal of organics, color, VOC/odor, ammonia and metals. Other benefits include improved sludge settleability/ thickening/dewatering, reduced effluent toxicity and very efficient nitrification at low temperatures.

The large amount of powdered carbon in PACT® systems also protects against shock and variable organic loadings, which are common in treating petrochemical/chemical wastewaters. USFilter's wet air regeneration system can be used with larger systems to regenerate the spent carbon while simultaneously destroying the biological solids.

GAC Adsorption

USFilter also offers systems as well as services for end-of-pipe filtration treatment that includes granular activated carbon (GAC) adsorption for treating effluent toxicity. Most activated carbon systems involve the continuous treatment of the contaminated water using two or more beds of GAC operating in series. The water being treated is in contact with the activated carbon for five to 10 minutes to ensure complete removal of the toxic organic compounds from the water. In biologically active systems the adsorption capacity and observed service life of the activated carbon can be significantly increased as a result of partial bio-regeneration of the GAC.

When one or more contaminants reach a specified breakthrough concentration between the two adsorber beds, the lead carbon adsorber in a carbon treatment train is considered to be spent and in need of change-out with either virgin or reactivated carbon.

The former lead vessel now containing fresh carbon is then moved to the end of the train, while the former second vessel assumes the lead position in the treatment process. This lead/lag operation of the adsorbers helps maximize organic loading on the carbon before change-out, thereby minimizing costs.

Spent carbon from a wastewater treatment process is normally sent to an off-site reactivation facility where a high temperature hydrothermal process is used to restore the carbon to near-virgin quality. Organic contaminants adsorbed on the carbon are completely destroyed during the reactivation process, reducing the generator's liabilities associated with the spent carbon.

Conclusion

Powdered and granular activated carbon-based solutions can help petrochemical/chemical plants meet stringent effluent bioassay requirements and also help improve the performance of their biological wastewater treatment systems. Activated carbon may also be used to treat wastewater, as well as contaminated groundwater and runoff at these plants. Using activated carbon in this manner allows the treatment facility to reduce the toxicity of its effluent water in an efficient and cost-effective manner.

About the Authors:

John A. Meidl is a product manager at USFilter Zimpro Products, located in Rothschild, WI. Jerry M. Ramdhani is director of sales at USFilter Westates Carbon.