By Walter P. Schaefer and John P. Pilsits Jr.

Scarce fresh water, multi-year droughts, gray water reuse, and water conservation all challenge the reliable operation of cooling water systems. Control of water chemistry in recirculating cooling water systems is critical to efficient cooling system operation.

Managers of open recirculating cooling water systems face ever-increasing challenges to maintain equipment reliability and efficiency, while minimizing employee risk and damage to the environment.

Online measurement of treatment performance can take system control to a new dimension of performance-based control and monitoring. With performance-based control, the cooling water can be safely pushed to higher cycles, or use poorer makeup water qualities than previously possible.

Stress Management

System stresses can have routine causes such as changes in cycles of concentration and variability in treatment chemicals, or more severe stress from efforts to conserve water or take advantage of less expensive or more readily available sources.

Examples of these increased stresses can include long holding time indices (HTI), high levels of scale-forming ions (Ca, Fe, Al, etc.), high suspended solids, uncontrolled microbiological populations, high oxidant concentrations, high skin temperatures and/or heat flux and low cooling water flow and/or velocity.

To address these sources of stress, operators can use a monitoring and control system which directly determines and controls cooling system performance online. The 3D Trasar®, one such example of this, is designed to monitor and control corrosion, fouling, and microbiological contamination.

Such a system should also capture all important cooling system data in one location for simplicity of analysis, convert this data to knowledge and make it available remotely to water treatment representatives and cooling system operators.

Corrosion Monitoring

It is not uncommon for months of great corrosion performance to be wiped out by a few unit upsets that may be missed if not for continuous monitoring.

Corrosion coupons can provide data on corrosion mechanisms and localized (pitting) attack. Linear Polarization Resistance (LPR) probes provide real-time general corrosion rates that can indicate the impact of changing operating conditions. Both techniques should be employed in every cooling water system.

Devices which use a combination of the two techniques, such as Nalco's NCM100, can help closely monitor corrosion rates and locations. The NCM100 is based on the LPR technique coupled with a transient technique (current interrupt) to provide accurate general corrosion readings in low conductivity waters (down to 5 µS/cm),

The LPR technology does have a couple of limitations. First, direct control of corrosion inhibitor dosage based on the LPR signal gives information on the corrosion rate which is specific to the exact location of the probe, and may not be indicative of corrosion rates at other locations within the cooling system.

Second, LPR probes tend to lack quantitative localized or pitting corrosion rates. While some LPR probes incorporate electrochemical techniques to allow determination of a "pitting index", this index is at best qualitative data that cannot be used for specific metal loss calculations and actions based upon these calculations.

Fouling Monitoring, Control

Fouling takes the form of deposition of hardness scale and of inorganic particulate matter. Upset conditions can form a deposit that may or may not dissolve easily, will likely impede heat transfer, and in severe cases, restrict or alter water flows.

A series of operating and water chemistry data is typically collected and analyzed on a sample basis to deduce system scaling and fouling risk. Since this analysis is performed at intervals ranging from once per shift to once a month, most system operators choose to stay far away from the perceived scale boundary by adding more water (running at lower cycles) and more treatment chemicals.

Fouling measurement with devices that simulate system heat transfer provide useful data, but they are limited in their ability to replicate changing conditions found throughout the entire cooling circuit.

A fouling monitoring and control system, the Nalco Scale Index, provides a 24/7 view of the system scale boundary and can help with fouling management decision-making. When system stress results in the potential formation of scale or particulate, the system can employ one of three control algorithms to either adjust the blowdown rate (cycle control), adjust the system pH, or adjust the chemical treatment dosage.

This technology relies upon the use of conventional inert fluorescent tracer technology coupled with a flourescently tagged dispersant polymer. As the tagged polymer is consumed in the system relative to the inert tracer, the increased consumption serves as a direct surrogate for the average system scale and particulate deposition rate.

Microbiological Monitoring

Experienced system practitioners realize that uncontrolled microbial populations in cooling water systems lead to extensive biofilm growth under deposit corrosion, and microbiologically induced corrosion (MIC).

Most monitoring and control techniques focus on detection of planktonic bacteria (plate cultures, dipslides, ATP) or control of biocide via oxidant residual measurements (ORP, DPD). The planktonic measurements are performance-based, but can be focused on the wrong problem. Typically, more than 99% of total system population resides in biofilms.

The residual biocide measurements, while offering real-time control of biocide feed, are not performance-based and may result in less than optimum results.

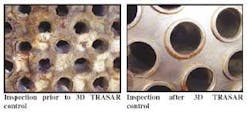

Control of the microbial population can be provided by the Nalco Bio Index, a performance-based microbial monitoring and control system. The system is able to detect microbes throughout the cooling system, which means that all planktonic and the majority of sessile organisms will be measured (water penetrates deep into biofilm layers). As the measurements indicate that microbial populations are starting to thrive, a control algorithm turns on the oxidizing biocide pump.

The pump is turned off once the populations die back down. These mini-slugs of oxidizer timed at the right time result in control of microbiological growth with efficient use of toxic biocides. As system biological nutrients or stress levels change (i.e., process leak, warmer temperatures, sunlight), the new control system responds immediately.

This technology is based on a proprietary BioReporter reagent that is independently introduced to the recirculating cooling water. The reagent has a characteristic fluorescent signature, which is enzymatically changed upon interaction with active microbes. The fluorescence of the BioReporter product (reacted signature) is monitored continuously by an in-line fluorometer, and the rate of change of the fluorescence with time gives a measure of the microbiological activity in the system. This signal is used to control the oxidizing biocide dosage to the system.

Currently, control algorithms exist for chlorine or bleach, stabilized bromine and sodium bromide.

Scale, Corrosion Inhibitor

Stabilized Phosphate and All-Organic chemistry remain treatment approaches of choice for many cooling water systems, especially in locations where application of corrosion inhibitors such as zinc and/or molybdate are restricted or deemed too expensive.

Although phosphate-based chemistry provides corrosion protection, pH variability, poor control of microbiological activity and long holding time indices often result in inefficient system operation, excessive water and chemical usage, or poor results that may ultimately require chemical cleaning of equipment.

A specially developed scale and corrosion inhibitor can improve performance under high stress conditions. For example, Nalco's Phosphinosuccinic Oligomer (PSO), is a component of the many Nalco phosphate treatment programs. A tagged, fluorescent high-stress polymer (HSP) is another component that permits higher system stress.

Tagged polymer control is an essential part of the Stabilized Phosphate treatment program for improved performance under high stress conditions.

Case Study

Poor operational control and high heat flux in a process heat exchanger in a West Coast refinery presented serious operational challenges. When originally installed, capital constraints prevented the installation of a necessary cooler. Without the cooler, the temperature difference across the exchanger was routinely 40-50 °F. Calcium phosphate (CaPO4) deposition was persistent and chemical cleanings routine.

Because the heat exchanger was critical to a capacity-limited process, removing the exchanger from service for cleaning required slowing production. The refinery was required to purchase hydrogen at a cost of about $2,200/day while the exchanger was running at reduced capacity or taken out of service for cleaning.

Initial conditions

A thorough review of the system uncovered three areas for improvement.

• Mechanical: Without the cooler ahead of the shift gas cooler, the exchanger was undersized for the application. High temperatures were a source of system stress.

• Operational: For the demand placed upon it, control of the water chemistry was not adequate. Operators made manual adjustments to treatment control based on routine testing. Response to upsets was slow and imprecise. Without better control, operational problems were unavoidable.

• Chemical: The makeup water chemistry varied between various city water, well water and reverse osmosis (RO) reject sources. These changes varied the stress on the system continuously, but there was no mechanism to detect the changes or respond to them.

Nalco recommended the 3D Trasar program in combination with a new PSO-based treatment program as a possible solution.

Performance

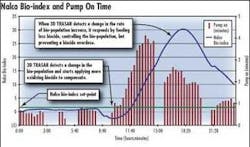

The refinery used a measure of system fouling to track exchanger performance. Degradation of exchanger performance signaled when cleaning was necessary.

Before the installation of 3D Trasar control, phosphate upsets put stress on the system which caused significant fouling. In one case, the overfeed caused a 14% efficiency loss in just a few days.

The exchanger fouling was being caused by the inability to detect and respond to changes in cycles of concentration, pH, phosphate concentration, variability of makeup water quality and high temperatures.

3D Trasar measured key parameters, detected upset conditions, took appropriate corrective action and communicated with operators. By managing the system based on the stress, it improved system control. Excess phosphate levels no longer resulted in significant loss of efficiency, and the exchanger fouling was reduced.

When system stress caused the active polymer levels to drop, the control system detected the change and increased the polymer feed to compensate. Later, the polymer feed was reduced when 3D Trasar detected that less polymer was required to deliver results.

Constant measurement of system stress by 3D Trasar controlled the amount of dispersant polymer needed to prevent calcium phosphate deposition. The control system detected changing stress from variations in temperature, pH, turbidity and phosphate levels, and applied the proper polymer concentration to address it.

Improved control did not completely eliminate the fouling. The high temperatures to which the exchanger was subjected called for changes in the chemical treatment program.

Nalco's PSO chemistry does not break down under high stress conditions. Combining the company's new corrosion inhibitor with the improved 3D Trasar control technology reduced phosphonate reversion and prevented deposition.

Attacking the problem with both improved control and improved chemistry addressed the mechanical, operational and chemical aspects of the problem.

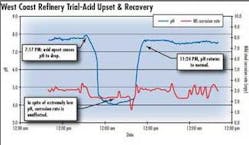

3D Trasar was also reactive to stressed pH conditions in this application. Two pH upset conditions increased treatment program stress for increased corrosion, but the control system maintained acceptable corrosion rates by adjusting treatment chemistries.

Return on investment:

• The refinery recognized a return on its investment in 3D Trasar by maintaining high production rates and avoiding the costs of cleanings, the total value of which was about $2,200 per day.

• The additional cooler was not needed, which eliminated a capital expense.

• The ability to maintain performance, even during periods when corrosion rates would otherwise have been elevated, prevented costly equipment repairs. During the trial, 3D Trasar and PSO chemistry began to improve heat exchanger performance.

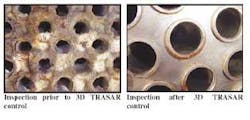

These benefits have been confirmed through equipment inspections. This exchanger had required cleaning during the last three inspections cycles; but with the new control system, cleaning is no longer necessary.IWW

About the Authors:

Walter P. Schaefer is a Nalco Technical Consultant for the Chemical Processing Industry. John P. Pilsits Jr. is a Research Scientist in Nalco Company's Cooling Water Research and Development division.

Editor's note: This article was excerpted from a larger paper presented during the 2003 Industrial Water Conference. The full version, with a complete set of illustrations, can be found in the conference proceedings from that event.