By Michael Gardner and Edith Garrett

In food processing and fresh-cut produce environments, chlorine is used as a sanitizer in product wash water, food transport flumes, equipment rinses, and hand dip. Chlorine will destroy bacteria, yeasts, molds, spores and viruses, significantly reducing their levels. Chlorine compounds are used also to control microbial growth in cooling systems. If your responsibilities include analyzing water for the presence of this important treatment chemical, a basic understanding of chlorine chemistry and chlorine testing options will allow you to obtain the most useful results possible.

Chlorine chemistry

When a chlorine compound is added to water it hydrolyzes to form a powerful sanitizer called hypochlorous acid (HOCl), a form of "free chlorine." For example, chlorine gas hydrolyzes into HOCl and muriatic acid (HCl), while sodium hypochlorite (NaOCl) hydrolyzes into HOCl and sodium ion (Na+). Hypochlorous acid itself can dissociate to form hydrogen ion (H+) and hypochlorite ion (OCl-), another form of free chlorine. This hypochlorite ion is not an effective sanitizer, however, and has only 1% of hypochlorous acid's germicidal power. In other words, free chlorine exists in water in both an effective form (hypochlorous acid) and an ineffective form (hypochlorite ion).

What determines how much of each exists? Primarily the pH of the water, though temperature also plays a role: Cooler water is better. At a lower pH, more chlorine is in the hypochlorous acid form; while at a higher pH, more hypochlorite ion is present. For this reason, both chlorine and pH should be monitored to ensure efficient sanitizer use. A pH somewhere between 6.0 and 7.0 will allow you to avoid corrosion of processing equipment, yet promote effective chlorine sanitation.

Free chlorine reacts immediately with contaminants in water until its disinfecting and oxidizing power is all used up. It kills potentially harmful microorganisms while also oxidizing organic matter. Ultimately, it reduces to inactive chloride ion (Cl-). It's important to note that during these processes, free chlorine reacts with nitrogen compounds to form "combined chlorine" — often called "chloramines." Combined chlorine is not nearly as effective at sanitizing as free chlorine. When measured together, they're referred to as "total chlorine":

Total Chlorine = Free Chlorine + Combined Chlorine

Effective testing plan

Now that a clear picture has been outlined of how chlorine works, the next step in analyzing your system for the best test method is to look at the production operations. Testing for chlorine is important not only for a snapshot of its effectiveness in a given system, but for ongoing confirmation that the water sanitation system is operating optimally.

Because free chlorine is depleted in more turbid water, it's important to know how clean the water is when deciding on a testing plan. In food processing, and particularly fresh-produce operations, water is frequently used in large amounts and is recirculated, increasing the probability of contamination. Engineering a circulation system that operates backwards in the production cycle and uses chlorination properly is one way to reduce this problem.

For instance, in the cut-produce industry an optimal circulation system is to have the incoming chlorinated water start at the end of the line at the final rinse phase. The water is then collected and circulated through the earlier wash steps back to the beginning of the line where it's disposed of. By handling the water this way, it can be the cleanest possible at the final stage of washing.

In this scenario, a survey of the water should be conducted to test for the reduction of free chlorine as it gets dirtier, identifying critical control points. The system can then be set to inject more chlorine compound at the correct intervals to maintain the proper amount of free chlorine throughout the process.

In other systems, the water may be continually recirculated with replenishment of fresh water occurring at some point in the cycle. In this scenario, the free chlorine levels also will be depleted with addition of organic matter. Testing free chlorine levels along the production line is valuable, but not a complete picture. Now, you need to survey over time as well. As production continues throughout the day, there will be a continuous buildup of contaminants to a saturation point. Depending on the product and system, the free chlorine levels will be depleted over time if chlorine isn't added back in the proper amount at the correct intervals.

Where possible, it makes sense to filter organic matter and other contaminants to reduce interference with free chlorine. A proper testing plan can uncover design flaws, provide a complete picture of the water chemistry, and create confidence in the water's safety. In the same vein, researching the best chlorine test methods for your particular operation will result in more accurate results.

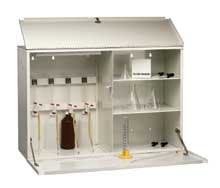

Testing options

A water sample with a total chlorine reading of 3.0 ppm could actually contain 2.8 ppm of combined chlorine and only 0.2 ppm of free chlorine – an insufficient residual to guarantee proper sanitation. In food processing applications, whereas total chlorine may need to be maintained as high as 200 ppm, the target range for free chlorine is generally 1-5 ppm. The International Fresh-cut Produce Association and other experts recommend monitoring free chlorine, not total chlorine, to ensure proper disinfection.

Four wet-chemistry methods are available for monitoring chlorine: OT (orthotolidine), iodometric, DPD (N,N-diethyl-p-phenylenediamine), and FAS-DPD (ferrous ammonium sulfate DPD). Because not all of these methods can distinguish between free chlorine and total chlorine, you need to be aware of this when selecting your testing supplies. Two additional cautions apply. When performing a colorimetric (color-matching) test, remember that color and/or turbidity in the untreated water sample will affect test results. Carrot processors, for instance, should be sure to choose a test kit that will compensate for this interference. In all cases, test water for chlorine as soon as possible after sampling since strong light and agitation will cause chlorine to dissipate, thereby decreasing the amount present.

OT method

In an OT colorimetric test, orthotolidine reagent is added to a water sample causing it to turn yellow in proportion to the concentration of total chlorine present. You match the developed hue to printed- or liquid-color standards to read the chlorine level. It's important to note that an OT test reads only the total chlorine in a sample. It won't allow you to make the important distinction between free and combined chlorine. OT can be used to measure total chlorine as high as 250 ppm.

Lodometric method

Like OT, the iodometric method will identify only total chlorine. It's used in drop-count tests or, for greater accuracy, buret titrations. When testing chlorine this way, the pH of the water sample must first be adjusted to between 3.0 and 4.0. Next, an indicator is added causing the sample to turn deep yellow-brown if chlorine is present. Then, thiosulfate is added until the sample turns pale yellow. After this, a more-sensitive starch indicator solution is added to enhance the titration's endpoint; it turns the solution a blue color. Finally, the titration with thiosulfate is continued until the solution changes from blue to colorless, signaling the endpoint of the titration. The total amount of thiosulfate added is multiplied by an equivalence factor (given in the test instructions) to obtain the total chlorine reading. Iodometric tests can measure total chlorine at any level.

DPD method

A DPD colorimetric test allows you to determine both free and total chlorine reliably in the range 0-10 ppm. (Levels over 10 ppm can be measured by diluting a water sample with non-chlorinated water and multiplying the test result by the appropriate factor.) A typical set of DPD color standards would show values for 1.0, 1.5, 2.0, 2.5, 3.0, 4.0 6, 8, and 10 ppm. (Interestingly, because pools are maintained in the same chlorine and pH ranges, some food processors use DPD pool test kits to measure these two values.)

A DPD test is easy to perform. DPD buffer and indicator are added to a sample, which then develops a pink color proportional to the amount of free chlorine in the sample. You match the developed shade to printed- or liquid-color standards to read the free chlorine level. If desired, a third DPD reagent included in some test kit models can then be added to the treated sample to obtain the total chlorine level.

FAS-DPD method

The FAS-DPD method is gaining in popularity with food processors for two reasons: 1) It reads free chlorine from 0-20 ppm with great accuracy; and, 2) it doesn't require the tester to be able to distinguish between shades of pink. Even someone with red-green colorblindness can see the change that occurs in the treated sample when it goes from bright pink to colorless.

The procedure for FAS-DPD testing is extremely simple. First, add a small scoop of DPD powder to the water sample. It will turn pink if free chlorine is present. Next, add FAS-DPD titrating reagent dropwise, swirling and counting after each drop until the solution changes from pink to colorless. Finally, multiply the number of drops used by the appropriate drop equivalence (one drop = 0.2 or 0.5 ppm) to obtain the free chlorine reading.

Conclusion

No matter what test method you choose, make sure it's measuring the correct form of chlorine for your operation, it's a method your employees can easily handle, and it will provide accurate information over time. The safety of the food system has never been more scrutinized or its security more questioned. Proper use of chlorine sanitizers can go a long way in providing confidence and assurance in today's environment.

About the Authors:

Michael Gardner is communications coordinator at Taylor Technologies Inc., a Sparks, Md.-based manufacturer of water analysis products for food and beverage operations, industrial processes, boilers and cooling systems, potable water and wastewater treatment, and pools and spas. For more information on chlorine tests for food processing, contact Taylor at 800-837-8548 or [email protected]. Edith Garrett has her own consulting company, E. Garrett & Associates, focusing on the fresh produce industry with over 18 years of experience in food safety, quality assurance, and customer relations. Most recently, she served 10 years as the president of the technical association, International Fresh-cut Produce Association (IFPA). For more information on food safety, she can be contacted at [email protected].