By Alan G. Knapp

Ultrapure water (UPW) is a valuable commodity in the semiconductor industry. Today’s market conditions and emphasis on environmental water conservation make it even more critical to find a process that will not only increase water availability but also minimize capital expenditures and existing floor space.

Challenge

A semiconductor facility in the Pacific Northwest needed to meet a recent increase in water demand. The makeup system consisted of double-pass reverse osmosis (RO), ultraviolet (UV), mixed-bed ion exchange and ancillary equipment. The facility considered expanding the existing equipment to meet water demands in the loop. This, however, would have significantly increased capital and operational costs, and required more floor space. The facility approached its primary water treatment supplier, USFilter, to come up with alternatives.

Solution

With these constraints in mind, USFilter evaluated all alternatives and recommended installing an ultrafiltration (UF) system that processes reject flow from the existing primary UPW UF system back directly to the UPW tank. This arrangement reduces the load on the makeup system and allows the facility to essentially recover 95% of the primary UF reject stream. The final remaining reject stream is recovered ahead of the RO units on the makeup system.

This skid-mounted, small footprint unit was easily added onto the current system as the modules were the same as the existing primary UPW UF system modules. This add-on configuration has not affected training operations and requires no additional spare parts inventory. In addition, the existing UF clean-in-place (CIP) cleaning skid and controls infrastructure can still be used to sanitize or clean the modules whenever necessary.

Results

Adding a reject UF system allowed the semiconductor facility to take the 50-gpm reject stream and recover 95% of the permeate directly back to the UPW storage tank. This resulted in an immediate makeup capacity boost of 47.5 gpm - about a 10% increase in flow to the manufacturing process.

To expand the makeup system would have cost the semiconductor facility more than $300,000. Installing the reject UF system for less than $100,000 proved to be a more cost-effective option. Compared to the makeup system expansion, the simple add-on solution also saved the customer considerable installation time, with no impact to the operating system.

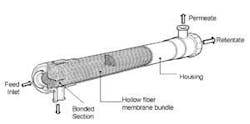

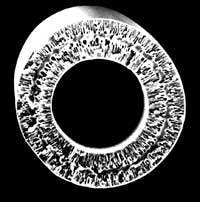

UF is an effective means of reducing particles in the UPW process with typical filtration at a 6,000-10,000 molecular weight cut-off (MWCO) level. The method involves multiple micro-membrane, hollow-fiber capillary tubes of polysulfone, encased in a bundle 4-6 inches in diameter. Ultrapure water passes through the membrane layer while a small reject stream is maintained to prevent buildup of particles on the membrane surface that can otherwise lead to scaling or fouling. These modules typically operate in the 35 gpm to 65 gpm (each) range.

Conclusion

Proper system evaluation can prove cost-effective and process-efficient for the semiconductor industry. When looking to increase availability of water in the makeup system, look for the following results:

• Increased quality and operational reliability by reducing makeup water demand;

•Reduced operating costs (energy for the RO pumps, mixed-bed resin throughput, manpower for maintenance);

• Minimal floor space consumption (15 sq ft, plus access area);

• Quicker upgrade than a major expansion to the conventional makeup system; and

• Capital equipment savings over $200,000.

About the Author: Alan G. Knapp is vice president and strategic account manager for the microelectronics industry at USFilter. Based in Portland, Ore., he joined USFilter about four years ago. He has over 19 years of water treatment industry experience, the majority of which has been focused on the microelectronics industry. A graduate of Conestoga College in Kitchener, Ont., Canada, Knapp is a mechanical engineering technician. Contact: 503-624-9793 or [email protected].