As a result of the Clean Water Act, operations such as food service, large scale laundries, meat packers and cosmetic manufacturers are faced with stricter industrial wastewater fats, oil and grease (FOG) limits. Food service and processing businesses need to size their grease traps and inceptors correctly to avoid “FOG clog,” which can lead to sewer piping problems and overflows. On the regulatory side, an accurate, quick and simple form of analysis can help ensure compliance. As such, the ASTM has passed a new test method to determine this faster and with greater accuracy.

Quick Results Correctly

Low levels of oil and grease are very difficult to measure directly in water. A solvent is used to extract the hydrocarbons from the sample and the measurement is done on the solvent. Before ozone layer depletion was an issue, Freon 113 was a universal solvent for extracting oil and grease from water. The solvent was either boiled off and the residue was weighed (gravimetrically) or infrared light was used to measure the hydrocarbons directly in the solvent. Infrared analysis offers a quick and simple measurement that can be done in the field in less than 10 minutes. Gravimetric analysis is limited to the laboratory and can take several hours to complete.

In 1999, the Environmental Protection Agency promulgated Method 1664 A to replace existing freon methods (see: www.epa.gov/waterscience/methods/oil.html). This method uses gravimetric analysis and hexane rather than Freon for extraction. Unfortunately, hexane is not a suitable solvent for infrared analysis by transmission since it contains hydrocarbons. Unless the hexane is removed through evaporation, those hydrocarbons will contribute to the oil and grease measurement. The evaporation phase of the gravimetric procedure will also loose the volatile constituents in a sample. Infrared analysis, on the other hand, can measure volatile components such as gasoline in a water sample. Because of the measurement capabilities, simplicity and portability of infrared analysis, the ASTM felt it was important to find an alternate solvent to freon and develop a suitable infrared oil and grease method.

New ASTM Method D7066-04

With the manufacture of Freon 113 banned by the Montreal Protocol in 1995, the old ASTM method (D 3921) that used infrared analysis and Freon 113 had to be replaced. Numerous oil and grease applications including EPA Methods 413.2 and 418.1and ASTM Method D 3921 used freon as the extraction solvent. The new ASTM Method (D 7066 - 04 Standard Test Method for dimer/trimer of chlorotrifluoroethylene (S-316) Recoverable Oil and Grease and Nonpolar Material by Infrared Determination) uses a similar extraction procedure with a more ozone friendly solvent called S-316.

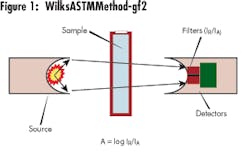

A variety of infrared instruments can be used with ASTM Method D7066-04, from full spectrum Fourier Transform Infrared (FTIR) spectrometers to portable, relatively inexpensive fixed filter infrared analyzers such as the Wilks InfraCal TOG/TPH analyzer in Figure 1. FTIR spectrometers can be found in most testing laboratories and are used for many applications in addition to oil and grease analysis. Portable, fixed filter infrared analyzers are application specific which makes them easier to use in the field or in-plant by personnel with relatively little training.

Ideal for On-Site Use

For screening or pretest applications, a state or federally approved method isn’t always necessary. Infrared determination of oil/grease concentration levels is quick and accurate and the ability to do the analysis on-site greatly expands its usefulness. It’s ideal for publicly owned treatment works (POTWs) where incoming trucks containing effluent are often tested for oil and grease levels. A 10-minute turnaround on a sample can greatly improve efficiency. Other applications include the ability of spill teams to quickly define contaminated areas or various industries to check their wastewater effluent to ensure permit compliance.

Similar Extraction Procedure

ASTM Method D 7066 - 04 has a similar extraction procedure as D 3921 and EPA Methods 413.2 and 418.1. Greatly simplified, the sample is acidified, a solvent (S 316) is added and after two minutes of shaking, a separatory funnel is used to remove the solvent from the bottom of the sample. For TOG (total oil and grease) the extract is then placed in a quartz cuvette to be measured by the infrared spectrometer or analyzer. For TPH (total petroleum hydrocarbons) the extract is passed though silica gel to remove the polar organics and then placed in the quartz cuvette. A beam of infrared light goes through the cuvette filled with extract and with either a filter set for C-H absorbance in a fixed filter infrared analyzer (see Figure 1) or the FTIR set to scan 2930 cm-1, and the hydrocarbon content is measured.

The extracted hydrocarbons absorb infrared energy at a common IR wavelength and the amount of energy absorbed is proportional to the concentration of the oil/grease in the solvent. The infrared absorbance value can be correlated directly to ppm, mg/liter or mg/kg. Like freon, S-316 can be reclaimed.

Conclusion

ASTM Method D 7066-04 is comparable to the earlier freon/infrared procedures in sampling methodology, offers many of the same advantages, and is useful for both the regulator and the wastewater producer. Not only does it save labor costs and potential out-of-compliance fees, but on-site testing can improve remediation efficiency. FT-IR spectrometers offer a more rapid oil and grease test in the laboratory while fixed filter portable IR analyzers, like the Wilks InfraCal TOG/TPH analyzers, are amenable to use in the field or wherever oil and grease measurements are needed.

About the Author: Sandra Rintoul is with Wilks Enterprise Inc., of South Norwalk, CT. Contact: 203-855-9136 or [email protected].