By Calvin Noling

Treatment of dilute storm and wash water in industrial environments can be challenging. The concentration and diversity of contaminants they contain requires a higher level of treatment than mechanical filtration or screening can provide, but doesn't necessarily justify selection of an enhanced wastewater treatment system. Often end-users select complicated chemical precipitation and filtration technologies. These technologies can be effective, but are costly to operate, involve handling dangerous chemicals and require trained operators who constantly monitor and tune the system.

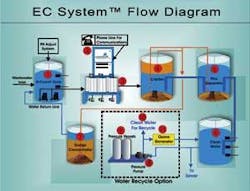

To address this treatment challenge, Stormwater Management Inc. recently released the Electrocoagulation System (EC System), an innovative water processing system for effective and economical treatment of industrial storm and wash water under a range of influent concentrations and compositions.

Using electrolytic cells, the automated system employs a controlled electrical current to remove emulsified oils, total petroleum hydrocarbons (TPH), turbidity, suspended solids and heavy metals from industrial storm and wash water. This significantly reduces power demand and operator attention, and eliminates the need for chemicals in many cases. To address customer's varied applications, the systems are available in turnkey units that can treat anywhere from 5 to 130 gpm.

How it works

For a typical installation, the EC System comes in a pre-packaged intermodal cargo container that sits above ground and can be located either inside or outside the facility. Pollutant removal begins when collected water in the system's influent tank is pumped through a series of electrolytic cells. As water passes through these cells, it is exposed to a controlled electrical current and becomes charged, causing suspended contaminant particles to bond together and form larger masses. The water is then transferred to a clarifier tank where lighter emulsified petroleum elements rise to the water surface and masses of heavier solids settle to the tank bottom. Separated contaminants are then pumped to a sludge accumulation tank while the clear phase of water is sent to a separator tank for removal of any remaining floc. The end result is clean water with fewer contaminants ready for reuse or for discharge to the sewer.

This electrolytic system is a programmed technology that's monitored and maintained by an onboard control system. It allows operators to make routine checks once or twice a day, as opposed to around-the-clock monitoring and maintenance required by mechanical and chemical systems. It also can be equipped with an optional telemetry system for remote monitoring and performance diagnostics.

The system draws only a minimal amount of power – approximate 15 amps on a 230V 3-phase circuit at 5 gpm – significantly less than mechanical systems. Computer control and minimal components make the system reliable and simple to maintain. Maintenance operations, such as periodic replacement of electrolytic plates, can be performed easily by maintenance personnel. In-depth diagnostic questions can be directed via phone to customer service representatives.

This system can also be used in conjunction with other treatment technologies, such as stormwater filtration systems, to treat "hot spots" in applications where greater quantities of contaminated water must be managed.

Conclusion

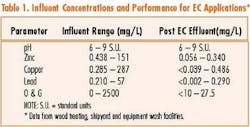

The high-quality effluent generated by the EC System brings users various benefits. It is up to 10 times better than that of mechanical systems, is suitable for reuse or discharge, and meets all discharge requirements under the NPDES regulations in a number of industry applications. Applications include transportation equipment cleaning, wood treating, quench water recycling, and marine applications such as hydroblasting, bilge water treatment, and hull washing. This system is especially well suited in situations where contaminant particles being removed are either so small they would pass through a typical filtration system or so numerous they would overwhelm it.

About the Author:

Calvin Noling, P.E., is industrial and remediation business director at Stormwater Management Inc., of Portland, OR, where he's responsible for industrial product development, applications engineering and sales. Noling has broad industrial stormwater and wastewater treatment experience, including permitting, planning, characterization, technology evaluation, design, and construction. He is also a co-author of Industrial Water Reuse and Management, published by the American Institute of Chemical Engineers. He can be reached at 800-548-4667 or [email protected]