By Dave Joseph

A cooling tower is something most plant personnel take for granted. The tower system produces a steady flow of plant water that’s continuously recycled with a minimum amount of bother and expense. Long-term operation of the tower, however, requires attention to the buildup of chemicals in the water and minimization of the three scourges: corrosion, scaling and biofouling. Luckily, there are specific analytical measurements to help you get a handle on each of these and still maintain the same number of concentration cycles, saving on water, chemicals and hardware. Analyzer vendors have bundled these measurements together in convenient packages for exactly this purpose.

Cycling accumulation

The primary difference between cooling water and makeup water coming from municipal sources is cooling water is recycled several times and tends to build up much higher levels of contamination. The ratio of contaminants is usually called “the number of concentration cycles,” and when the tower is running 10 cycles, there are roughly 10 times as many contaminants present as in the source water. A little water is periodically removed and replaced with fresh water during blowdown to prevent excess buildup of contamination. Blowdown can be on a timer or, more efficiently, based on the total dissolved solids (TDS) level, usually measured with electrical conductivity. When the TDS level is too high, some of the less soluble compounds may solidify and partially block process lines. This problem is aggravated in areas with hard water that are more prone to solids deposition. Conductivity (or TDS) is used as an indicator of the potential for scaling even though the bulk of the chemicals called TDS dissolve readily in water and do not cause scale.

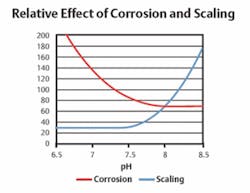

The optimum level of TDS in cooling water depends on many factors including pH, makeup water quality, water cost, treatment chemical program, maintenance, and energy cost. For most applications, there’s an operational sweet spot around pH 8 that limits both buildup of scale present at higher pH and corrosion that mainly occurs at lower pH. When makeup water is expensive, more cycles allow higher reuse of water and a higher TDS setpoint may be desired. The availability of soft water may allow more cycles before scaling occurs. Treatment chemicals protect metal surfaces against corrosion and can change the cooling water pH. Operating at higher TDS levels may be a good short-term policy but may lead to long-term increased maintenance and replacement costs while limiting heat transfer due to scaling - and heat transfer is the whole point of cooling water!

Tracking the Big Three

Monitoring your cooling tower boils down to careful tracking and control of three analytical measurements to prevent any solids forming in the cooling tower. The most common are: pH, conductivity and ORP. pH is used primarily to prevent operation under acidic conditions that can quickly lead to corrosion. This is especially important because sulfuric acid is typically added to the water to keep the pH from rising due to reuse of alkaline raw water. Since pH is a logarithmic measurement, even slight overfeeding of acid can drive the pH below 7. pH sensor response time is key here, so sensors should be kept clean by installing them in locations with ample flow and away from dead spaces that can build up solids. Look for sensors designed to withstand processes where coating/clogging with hard water deposits and/or biofilm are common, and control scaling and biofouling as much as possible. In some cases, a corrosivity measurement is used as further insurance against corrosion damage.

Many water treatment chemicals are available to extend the lifetime of metal components in the cooling tower. Orthophosphates and polyphosphates are the most common inorganic chemicals since they inhibit both cathodic and anodic corrosion reactions. Organic inhibitors such as azoles form films over metal surfaces that can protect without limiting heat transfer.

Electrical conductivity measures the presence of all dissolved ions in solution, and is commonly used as an online indicator for the degree of potential scaling. Solubility indices like the Langelier’s Saturation Index (LSI) for calcium carbonate are used to determine that the cooling system can perform under a certain number of cycles and at a given pH. The LSI will trend with conductivity for a specific cooling tower. When conductivity exceeds the setpoint, the blowdown valve is opened and fresh water is added to the system. Conductivity levels typically rise slowly over time and then drop periodically when blowdown occurs. Sensor response isn’t usually critical, though buildup due to biofouling can cause readings to be lower than expected. In some cases, using electrodeless (toroidal) conductivity sensors will provide a more robust measurement when sensor maintenance isn’t possible.

Oxidizing Biofoulants

Cooling towers use large volumes of air during operation and capture all sorts of microorganisms from the atmosphere. Under proper circumstances, slime-forming microorganisms can take up residence in certain low-flow areas in the systems forming an insulating film, inhibiting heat transfer and fostering corrosion. Oxidizing biocides such as chlorine, bromine, peroxide and chlorine dioxide are commonly added to cooling water to discourage biological growth. The presence of these strong oxidants can be measured with an ORP sensor that detects the overall oxidizing or reducing potential of a solution. Although it can be difficult to correlate ppm levels of chlorine or bromine to specific ORP levels, those in the 400-500 mV range are good indicators of a protected tower while levels below 200 mV indicate a potential problem.

Establishing limits on the oxidant feed rate and regular checking of the oxidant level using titration is a good practice to avoid overfeeding since ORP may not provide an easily detectable endpoint. Sometimes biocides are fed intermittently, where the tower is shocked with high levels of 1-5 ppm for 10 minutes every day or so as a preventive measure. This technique is sufficient for a clean system with no dead areas, but may not provide enough protection to low flow areas. In areas where the discharge of blowdown water is regulated, it may be advisable to make a direct ppm measurement of the specific oxidant being used. Free chlorine and total chlorine analyzers can accurately control chlorine addition under these circumstances.

Conclusion

When carefully tracked and adjusted, these three analytical measurements - pH, conductivity and ORP - work well together to protect cooling water chemistry. When pH is well controlled, less treatment chemicals are needed, more cycles can be used, and conductivity can be used to control blowdown. pH also affects the disinfecting properties of chlorine, so a well controlled pH can mean a lower biocide feed rate. When coating from scaling and biological growth is limited, the pH sensor is clean and responds quicker, providing better control. These are truly synergistic measurements. All three can be measured in one package in a convenient flow system. With proper attention to water chemistry, this type of system may again allow you to take your cooling water for granted. IWW

About the Author: Dave Joseph is a senior industry manager with Emerson Process Management at the Liquid Division of its Rosemount Analytical Inc. For more information, contact 800-854-8257 or see: www.emersonprocess.com/raihome/liquid/.