By Al Fosco

Superior Mold of Ontario, Calif, a maker of tight-tolerance parts for the medical and aerospace industries, had been using a 15-ton cooling tower and a 10-ton chiller for its cooling needs. Management felt the system was not aiding their ability to reach more competitive production cycle times and it was also a strain on water, energy, chemical and maintenance costs for the facility.

Many of these challenges stemmed from the plant's location in the path of the Santa Ana winds, which blow sand and hot air from the desert. The tower system in place was regularly exposed to sand and dust. It required special filtration, as well as additional water consumption and treatment to make it useable, and to ensure the processing equipment wasn't being impaired by dirty water.

Superior Mold worked with a third-party energy consultant to audit its current system and analyze replacement options including an air-cooled chiller system and a closed-loop cooling system. Following this, the decision was made to install an Ecodry closed-loop dry cooling system from Friegel North America.

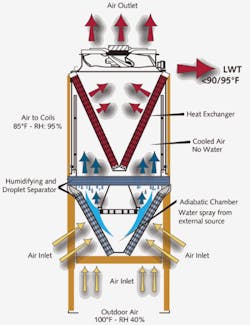

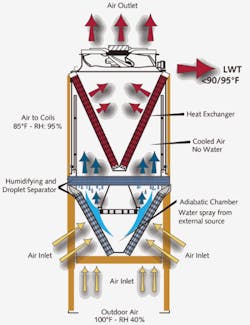

Whereas conventional cooling towers use evaporation to reduce process water temperature, the modular, pre-engineered Ecodry system uses ambient air to cool the water. In place of a cooling tower, the system features a closed-circuit fluid cooler. The water returning from the process is pumped into heat exchangers and cooled with ambient air flow.

In a typical Ecodry installation, when ambient air hits 85°F or higher, it passes through an "adiabatic chamber" before reaching the heat exchanger. Water from a secondary source is "pulsed" into the chamber, and the resulting humidified air drops the closed-circuit cooling system water temperature to at or below 95°F, even with ambient temperatures as high as 120°F. To ensure consistent cooling, the system's control panel continuously adjusts the amount of water sprayed. The heat exchanger, meanwhile, remains completely dry.

Under cold weather conditions, if ambient air dips below 32°F, Ecodry has a fully-automatic, self-draining system that protects it from freezing.

Among the other advantages, the new system offers the potential for free cooling (meaning turning off the chillers) when ambient conditions permit. The control system monitors outside air temperature and, when appropriate, effectively shuts down the compressors.

Energy, Water Savings

The system's variable speed fans are controlled to provide the amount of energy required to compensate for the exact cooling load, process temperature and outside air temperature at any time. Compared to the typical on/off fan cycling system, the variable speed fan and control system can reduce fan energy by as much as 25%.

The system also features pump motors that are 8% more efficient than standard pumps on conventional systems. Fluid dynamic efficiency is even better–14% higher than conventionally available pumps. The company claims pump electrical energy consumption can be reduced by as much as 50% with its efficient motor and pump designs.

The closed loop system also offers water related efficiencies. In traditional cooling tower systems, the water loop is exposed to outside air and also contaminated by that air. That can lead to scaled, plugged heat exchange surfaces, decreased equipment efficiency and increased electrical operating costs. In contrast, water in the closed loop system does not come into contact with outside air. As a result the system can reduce water and sewage costs associated with conventional cooling towers.

Project Installation

Superior Mold replaced its chiller and cooling tower with a 34-ton Ecodry unit to cool its six all-electric injection molding machines that were part of its Class 100,000 cleanroom. Frigel configured the unit to work with the plant's existing piping system and overall, operations were simplified by bringing two cooling systems down to one.

The result to date has been a 60 percent reduction in process cooling related energy bills and a 90 percent reduction in water and chemical usage. Cleaner water has eliminated the concern about machine contamination and has also played a positive role in the company's environmental initiatives.

The installation of an Ecodry System was met with a 30 percent rebate check from the State of California based on the energy savings the company was able to achieve. The expected payback on Superior Mold's investment is approximately 12 months on this project. IWW

About the Author: Al Fosco, a 30-year veteran of process cooling equipment and systems design and manufacturing, is Industrial Markets Sales Manager for Frigel North America. Although the company's closed-loop, dry-cooling system is relatively new to North America, it has been used over the past decade at thousands of installations worldwide More information on the system can be found on the Frigel website at www.frigel.com/na.

Past IWW Issues