By Richard Baril

Ensuring that the water being delivered to communities is of the highest quality has always been top priority for water utilities across the country. Now more than ever the focus on safety is a national priority. The Department of Homeland Security has charged the EPA with ensuring the water supply is safe, and the EPA is now requiring that plants submit a plan on how they secure their distribution networks. Utilities must now put into place effective security policies and procedures to ensure water quality and safety. That job is now more complex than ever before. Between aging infrastructure and limited resources, there can be points of vulnerability in numerous areas throughout the water distribution system.

Utilities must be equipped to identify points of security vulnerability and take steps to secure the water distribution system as much as possible. However, in striving for security, it is not feasible for plants to turn the whole operation upside-down. It is not feasible to test for every possible variable in the water at any given time, but there are reasonable precautions one can take that will ensure water quality and safety.

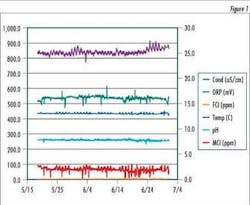

The only way utilities can detect a problem in the water is to identify change in the water composition and understand what various changes could indicate. In order to detect any change, utilities must continuously monitor on-line both the raw and processed water throughout the system to get a baseline for the normal water composition. It's best to have baseline data for at least a year in order to understand, monitor and detect patterns. Once that baseline is determined, operators can then make informed judgments when changes beyond the normal patterns emerge that could be cause for concern. In today's environment, continuous on-line monitoring is clearly becoming more and more important, and the industry will adopt it as standard procedure.

The first question many utilities ask when determining how to go about installing continuous on-line monitoring systems to help secure water quality is, "How many early warning monitors does my plant need?" For many the answer to this question is often as many as it can afford. It's important to do a security vulnerability assessment to determine the likely points of weakness in the water distribution system. Utilities will most often find several points of vulnerability throughout the distribution, and it's best to install a water quality system in each of these weak areas, or at least in as many of them as is affordable.

When selecting instrumentation for continuous on-line monitoring, it's important to evaluate several factors. In terms of cost, in addition to the cost of the system, the plant must also understand what the total cost of any disruption, training and maintenance will be.

When selecting a partner to implement this kind of a water quality monitoring system, utilities must understand that no one solution will fit every plant, and they should be wary of vendors that sell only one pre-packaged solution. Each plant has its own individual points of vulnerability it must protect and its own needs in terms of cost, training and maintenance, so the solution should be flexible enough to be customized as much or as little as the plant requires.

In addition, it's important the utility selects instrumentation that's been proven to be reliable and have a long-life even in the harshest environments. Sensors that have proven they can stand up to harsh applications, such as those in chemical or pulp and paper processing, will need to be replaced less often than sensors that are normally used in more benign applications, such as lab environments.

Another cost factor that plants must consider during the selection process is total cost of ownership, such as installation, training and maintenance requirements. Some instruments available in water quality monitoring systems are easy to use and minimize training and start-up time. Using smart instruments allows analyzer and sensor diagnostic information to be accessed by the operator to eliminate false positive alarms caused by instrument or sensor failures.

In addition, many long-life sensors require so little maintenance that operators do not need to interact with the analysis system on a day-to-day basis. In terms of installation, there are a couple of options utilities can choose from depending on their needs. They can choose a system that comes pre-integrated with a complete process control system and, in that case, installation is greatly simplified. A utility may also select a plug-and-plumb system that is compatible with an existing SCADA system.

A complete solution for water quality protection should incorporate the continuous measurement of the following parameters:

• pH – to detect changes that impact the potential corrosion of the distribution network

• ORP – to determine the level of chemical reactivity

• Conductivity – to provide an indication of total dissolved solids

• Free Chlorine – to maintain optimum residual disinfection levels

• Monochloramine – to monitor effective disinfection levels

• Ammonium – to determine if enough ammonia is present to complete monochloramine reaction

• Dissolved Oxygen – to indicate if a healthy environment exists

• Turbidity – to indicate biological growth and suspended matter

The days of using only grab sample analysis are coming to an end. The key to a safe and secure water quality system in today's environment is to use established parameters to measure change over time by continuously monitoring at various locations throughout the water distribution network. By monitoring patterns and detecting changes in these patterns, utilities can be better prepared to detect problems in the water before those problems affect the communities they serve.

About the Author:

Richard Baril, Product Marketing Manager, Emerson Process Management, Rosemount Analytical, Liquid Division has been active in the drinking water, wastewater and process industries for over 17 years. He is a current board member for the International Ozone Association, has spoken at several industry conferences and has authored numerous articles in a variety of publications.