By Brian Gallagher and Chad Prior

In today’s lexicon, the word “concrete” has come to symbolize strength, stability and the image of being set in stone. With this seeming permanence, it is no wonder that concrete is the most common solution for the water and wastewater industry for storage tanks. Beyond the inherent durability of concrete, a variety of post-tensioning and corrosion protection techniques are providing even longer-lasting and economical solutions.

With a basic understanding of prestressed, post-tensioned concrete and recently enhanced multistrand and monostrand systems, industry professionals can select the optimal solution for their next water storage or process tank.

According to the American Concrete Institute (ACI), prestressed concrete is a material that has had internal stresses induced to balance out stresses due to self-weight and externally applied loads. Since tensile stresses may be undesirable in certain concrete members, the objective of prestressing is to create compressive stresses to counteract or eliminate the undesirable tensile stresses within the member, and in many cases to apply a net “residual compression” to the member.

The reduction of tensile stresses within the concrete, or application of residual compression, will result in members that have minimal cracking or are crack-free under the most extreme loading conditions. This is one of the advantages of prestressed concrete over conventionally reinforced concrete, particularly in corrosive atmospheres such found in moist, chemical-laden environments.

The normal method for applying prestress force to a concrete member is through the use of high strength, 7-wire steel strands. There are two basic methods of arriving at the final prestressed member: pre-tensioning and post-tensioning. Pre-tensioning is defined as a method of prestressing concrete in which the strands are stressed or tensioned before the concrete is placed. This method is normally associated with members manufactured at a precast facility. Post-tensioning is defined as a method of prestressing concrete in which the tendons are tensioned after the concrete has reached a minimum initial strength and this method is normally associated with members cast in-place at a job site.

According to Daniel Harger, PE, Division Manager for VSL - a company involved in the design, manufacture and installation of post-tensioning and special construction systems - post-tensioning has proven to be a high quality and economical solution for tanks.

For security and aesthetic reasons, many tendon tanks are partially or fully buried to limit visibility and access. Since there are no coatings or liners required for water tightness, post-tensioned tanks are relatively maintenance-free. Additionally, the floor and roof slabs are typically cast in single placements, eliminating construction and maintenance costs associated with construction joints, Harger said.

“The use of post-tensioning in water storage and water treatment tanks has increased significantly over the past several years,” Harger said. “Post-tensioned tanks have superior corrosion protection for the prestressing steel, including thick concrete covers that are bi-axially prestressed, watertight polyethylene ducts, and high-performance cementitious grouts.

While post-tensioned concrete storage tanks have been a proven solution for almost 30 years, recent advances in post-tensioning systems technology allow for even greater durability.

According to Harger, multistrand and monostrand systems are being integrated as solutions for the water storage tank industry. Multistrand systems, also known as bonded systems, consist of strands placed in watertight ducts that are injected with high-performance cementitious grouts after the strands are tensioned. Monostrand systems, also known as unbonded systems, consist of strands that are coated with a rust-inhibiting grease and a continuously extruded protective polyethylene sheathing.

Case Study

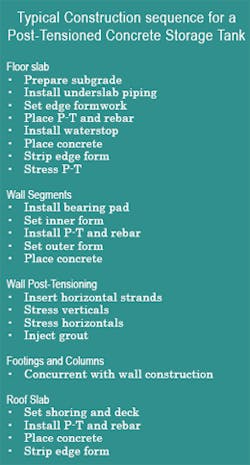

A good example of this terminology and technology is a post-tensioned tank at the East Cherry Creek Valley Water and Sanitation District in Aurora, CO. The project features a 10 million gallon circular storage tank measuring 288 feet in diameter and 22 feet in height. The floor consists of a five-inch-thick membrane orthogonally prestressed with fully-encapsulated unbonded post-tensioning tendons. Stage stressing of the tendons was used to provide pre-compression to the concrete as soon as possible after placement to minimize or eliminate early shrinkage cracking. The post-tensioned membrane floor was cast in a single pour to eliminate construction joints - a potential source for leakage into and out of the reservoir.

The 12-inch-thick wall was cast in place in 12 full-height segments equal in length; four of the segments contain pilasters for stressing the horizontal tendons. Prestressing was accomplished with internal tendon-type post-tensioning systems both circumferentially and vertically to ensure crack free service.

The multiple layers of corrosion protection on the prestressing strands include high-performance grout injected into the polyethylene ducts encased in the densely compacted wall concrete. High levels of concrete pre-compression provided by the post-tensioning tendons, under the most extreme loading conditions, eliminate tensile stresses and ensure a durable structure.

The roof is composed of a 7.5 inch column supported by a two-way prestressed concrete flat plate. Similar to the floor slab, it is also orthogonally prestressed with fully encapsulated post-tensioning tendons and stage stressed to limit concrete tensile stresses.

“The long-term durability and lack of required maintenance associated with steel tanks, such as dewatering, sandblasting, refilling and repainting, allow the post-tensioned concrete tank to serve as an attractive option,” said Robert Bates, PE, President and founder of Bates Engineering, and structural engineer for the project. “Further, since the tanks can be completely buried in the ground, allowing for limited access and visibility, security and safety are increased - a concern for everyone in today’s world.”

About the Authors:

Brian Gallagher is Director of Marketing at VSL. Chad Prior is Marketing Manager at the company. VSL designs, manufactures and installs post-tensioning and specialty reinforcement systems. For more information, visit www.vsl.net or call Gallagher at 410-850-7000.