by Allan R. Budris

My September 2007 column dealt with energy savings potential for pumps and pumping systems (which are substantial), while the November 2007 column presented criteria to help identify which pumping systems have the greatest potential for savings. However, rough estimates can be misleading when it comes to identifying the true magnitude of the energy savings potential for a specific system.

While conducting an extensive energy audit for a major Great Lakes pump user, the writer was presented with an application where a prior consultant had estimated cost savings of over $50,000 per year, by the addition of a variable speed drive to one of their pumps, using rough estimates. The user was in the process of acting on this recommendation. However, by field testing the pump, and conducting a more detailed analysis, the annual energy saving potential for the variable speed drive was found to be only $5,000, hardly worth doing.

I am sure that many pump users have been disappointed by the low level of energy savings actually achieved with some of their prior energy reduction programs. The only way to avoid these disappointments is to conduct a proper detailed analysis of the current system and the potential cost savings options, and to compare the differences.

A proper detailed pump system energy audit should include the following activities:

1. Identify the pumps and pumping systems that offer the greatest energy savings potential, with minimum effort, as detailed in the November 2007 column, and prioritize the most attractive systems.

2. Collect key detail information on these pump and systems, including:

a. The system flow rate objectives. What are the required future flow rates, not just the average, but also the minimum and the maximum. The average flow rate is needed to calculate the energy usage, while the maximum flow rate dictates the pump size. The minimum flow rate can be an issue with respect to the pump minimum allowable flow.

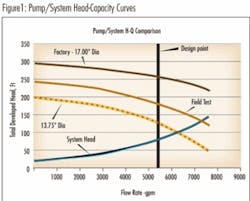

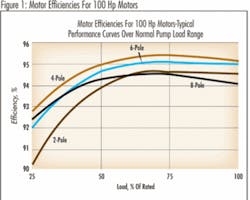

b. The actual system head vs. flow curve. Field tests may be required to establish the system curve. Once the installation is complete, the system head vs. flow curve can be obtained with three basic measurements. The total head at one specific flow rate, and the static system head. The total system head is comprised of the static head plus the friction head. The system static head is made up of the elevation head, plus any static pressure that the system must discharge into. The difference between the total system head and the static head is the system friction head. The friction head for other flow rates can be determined by using the square rule. The friction head varies as the square of the flow rate, so if the flow rate doubles, the friction head increases by a factor of four. The static head should then be added back to the various friction head values to establish the full system total head curve (figure 1).

c. What are the pressure drops across the various system valves and other major components at the average flow rate (or field test rate)? What is the pressure drop across the control valve when it is 100% open, and at the average system flow rate? Are any of these pressure drops excessive?

d. The as-new (pump manufacturer’s factory) pump head-capacity and power vs. capacity (flow rate) curves. This can later be used to determine if the pump performance has degraded over time from internal wear or corrosion.

e. The actual current pump head-capacity and power vs. capacity curves. A field test should be performed, if at all possible, to obtain this information, using calibrated instruments. Field bourdon type pressure gauges are notoriously inaccurate. As many flow points should be taken as the system will allow. If only one point can be taken, the shape of the factory curve can be used to approximate other flow rate points. If the flow rate cannot be measured, the input power (accounting for the driver efficiency), can be obtained from the factory power vs. capacity curve to estimate the pump flow rate. Figure 1 shows a plot of an actual system, factory pump (at two impeller diameters) and actual field test pump curves. The pump will always operate at the intersection between the actual pump and system H-Q curves.

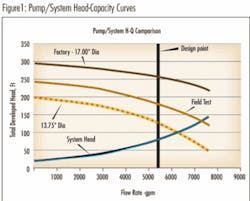

f. Determine the efficiency vs. power curve for the motor. Motor efficiency varies based on the percent of rated power (see figure 2); speed; power level; and motor efficiency rating (standard, energy-efficiency or premium-efficiency).

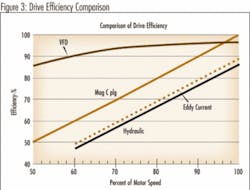

g. Determine the efficiency vs. power curve for any variable speed drive, such as a variable frequency inverter (see figure 3). VFD efficiencies range from about 97% at 100% of rated speed, to around 91% at 50% of rated speed. Total VFD/motor efficiency values can range from 65% to 83% at 40% of rated speed, to 86% to 93% at 100% rated speed.

h. Collect the repair service record for the pump(s). What is the mean-time-between failure? What type of failures has the pump had? How long has it been since the last overhaul? This can help to identify appropriate improvement options.

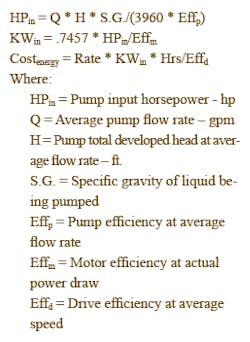

3. Based on the above collected data, the current annual energy cost should be calculated at the average flow rate, using the below equations:

The above calculations should be repeated for each of the potential energy saving options (see September 2007 column for a list of cost savings options), and compared with the current costs results. Finally, can the calculated savings justify the capital cost required to accomplish the necessary changes?

Using the above methodology the writer was able to identify over $2,000,000 in annual energy savings for one major pump user.

About the Author:

Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].