by E. Charles Wunz, P.E., BCEE and Christopher Graf, P.E.

It’s fair to say most sanitary or wastewater engineers have little exposure to anaerobic treatment technologies except in the case of sludge digestion. Even the newer membrane bioreactor (MBR) and sequencing batch reactor (SBR) treatment technologies are simply different ways to implement activated sludge.

Though largely unused by U.S. municipal wastewater treatment plants, anaerobic treatment could be a cost-effective solution to many challenges facing the industry today: rising energy costs, high sludge disposal costs and tighter effluent limitations. Properly designed anaerobic treatment systems have the potential to provide a renewable energy source (biogas), consume less energy, generate less sludge, and offer a source for methanol replacement (effluent from anaerobic acid phase reaction).

The Milton Regional Sewer Authority’s Wastewater to Energy Project (Ww2E) highlights the positive results anaerobic treatment technologies can produce for municipal treatment plants.

Located in Central Pennsylvania, Milton serves residential customers and the manufacturing facilities of Con Agra, which produces Chef Boyardee, Healthy Choice, Andy Capp, LaChoy, and Gulden’s Mustard foods. Its existing wastewater treatment plant was commissioned in 1975 and was designed to provide secondary treatment to 2.6 mgd and 16,000 pounds of BOD5. Of this capacity, 1.3 mgd and 13,000 pounds of BOD5 were allocated to Con Agra. The manufacturer installed a pre-treatment plant, and Milton adopted a Municipal Industrial Pre-treatment Program.

Still, Milton could not successfully treat Con Agra’s high-load, nutrient-deficient wastewater to regulatory standards until the authority implemented a biological and chemical augmentation program, which today costs them $140,000 annually to continue. In addition, the sludge digestion, dewatering and holding facilities of the 1975 design were inadequate to process the amount of sludge being produced once NPDES compliance occurred. Milton currently spends more than $400,000 each year on sludge disposal and $360,000 each year on electricity, a price they expect to rise by 20-40% later this decade when Pennsylvania deregulates the energy industry.

So, even though the biological and chemical augmentation program was successful in achieving NPDES compliance and even allowed the plant to be re-rated to new capacities of 3.42 mgd and 18,000 pounds per day of BOD5 beginning in the mid- and late 1990s, the high cost of chemicals, electricity, and landfilling compelled Milton to produce a new basis of design for an upgraded and expanded plant earlier this decade.

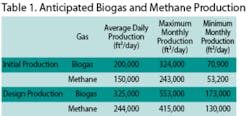

This new basis of design evaluated a number of treatment process options, including both high-load and low-load anaerobic treatment for the segregated Con Agra wastewater. Pilot testing of a low-load anaerobic process provided by ADI proved that 60 to 80 percent of the incoming Con Agra BOD5 could be removed in the anaerobic process, which would, in turn, generate a biogas containing 75 percent methane. Milton’s Ww2E project was conceived: This methane could be fed to an internal combustion engine coupled to a generator (thereby producing electricity and heat). The electricity would be used to power the treatment process, and the heat would be used to dry the remaining biosolids.

Beginning in 2006, final planning and design of the Ww2E project began. It consisted of the following:

Slated for construction in 2009, the upgraded plant will include two 7.5 million gallon ADI-BVF reactors to anaerobically treat the influent ConAgra wastewater. In addition, the strength of the ConAgra wastewater will be increased by 30 percent through removal of the company’s pretreatment screening and settling processes. The ADI-BVF reactors will reduce the wastewater strength by 90 percent while creating usable biogas as a by-product of the reaction. The biomass yield is low at 0.11 lb VSS per pound BOD applied, roughly 80 percent less than a typical aerobic process.

It should be noted that Milton does benefit from the temperature of the Con Agra discharge, which is on the order of 105° F. (near the center of the mesophilic methanogenic range). Methane production does occur at much lower temperatures than that and the acid forming phases of anaerobic treatment occur at even lower temperatures, so the presence of warm industrial wastewater is not necessarily required to allow the cost effective application of anaerobic treatment technologies. For example, an anaerobic reaction ending at the acid production phase without methane production could result in an effluent idealized as a methanol addition substitute for biological nitrogen and phosphorus removal.

Energy Benefits

Applied aeration energy needs will be reduced by 45 percent even though the flow will increase from 3.42 mgd to 4.6 mgd (32 percent increase) and the loading will increase from 23,800 to 65,000 pounds BOD5 per day (200 percent increase). Overall energy consumption at the plant will be reduced by 30 percent.

The annual average electrical energy requirement will be reduced to 300 kW through the use of energy efficient processes. In addition, electrical generating equipment will be capable of generating between 600 kW and 1300 kW of electricity using the biogas produced from Con Agra’s wastewater, based on the results of the pilot test and estimates of anticipated future ConAgra flows. From this data, it is estimated that capacity will exist to provide over 1.3 MW of electricity at build-out – less than half of which will be required to power the treatment plant. Therefore, Milton will be able to eliminate more than $300,000 in annual electricity costs while producing additional revenue by selling the excess electricity to the local utility.

While still being negotiated, it is conservatively anticipated that electrical power can be purchased for $0.077/kW-hr ($0.087/kW-hr less $0.01/kW-hr line charge) and sold for $0.066/kW-hr. This yields a yearly gross benefit between $375,000 and $722,700. Operation and maintenance costs for the generator will range between $170,000 and $340,000 including labor, maintenance, hydrogen sulfide media replacement, and parts. The largest operation and maintenance cost is for gas scrubbing media replacement at between $80,000 and $160,000.

Waste heat generation from the generators will be 4.73 mmBTU/hr, and the usable fraction of this waste heat will be used to dry the remaining biosolids. This provides an additional net savings on the solids handling process of $21.75 per wet ton or $231,000 per year.

Total operation and maintenance savings for electricity and solids handling alone are between $436,000 and $613,700, annually. This savings would support between $15 million and $21 million in debt service.

Furthermore, sludge production will be reduced by 90% using this design, and the current cost incurred for landfilling this sludge will be eliminated. The dried biosolids will be either sold as a soil amendment or fertilizer or as a renewable fuel to a nearby cogeneration plant.

This $420,000 gross savings on landfilling together with the savings on electricity purchase and the earnings associated with electricity sales provide significant opportunities to largely fund the debt service on the cost of the improvements. (The estimated construction cost of the upgraded plant is $32 million.)

But these are not the only economic benefits produced by this project. This upgrade will provide ample capacity for a planned expansion at the Con Agra manufacturing facility that is anticipated to create 100 jobs in the local region. The expanded treatment plant will also have ample capacity to accommodate additional future expansions, as needed, and there is discussion of supporting a high strength wastewater discharge industrial park to attract other industries.

The community will also benefit from the project environmentally. The most obvious benefits will be the reduced consumption of landfill space (due to the elimination of sludge disposal) and reduced reliance on fossil fuels (thanks to the creation of renewable energy). Total carbon dioxide emissions (the sum of power plant and treatment plant emissions) will be reduced, as well.

Milton’s example shows that anaerobic treatment processes can be implemented to drastically reduce energy and sludge disposal costs for municipal wastewater treatment plants, and these operations and maintenance savings – coupled with the potential revenue earned from selling the renewable energy it produces – can largely fund the upgrades such a conversion would require.

About the Authors:

E. Charles Wunz, P.E., DEE, is the executive vice president of Herbert, Rowland & Grubic. He has extensive experience in the planning, design, and construction of water and wastewater treatment facilities and is the project manager in charge of designing the Milton Regional Sewer Authority’s new treatment plant. He is also a nationally recognized expert witness in cases related to water and wastewater infrastructure improvements and their impact on user rates. He can be reached by email at [email protected]. Christopher Graf, P.E., is a project engineer at Herbert, Rowland & Grubic. with seven years of experience designing water and wastewater systems infrastructure. He may be contacted at [email protected].