By Jodi Glover and Tylor Hauger

With the increasing awareness about the negative effects of organics within the water and wastewater treatment process along with increasingly strict water quality regulations, the need for real time organics monitoring is becoming more important.

One of the most problematic types of organics is the aromatic varieties. The double bond ring structure of aromatic molecules results in free electrons. These free electrons make aromatic organics react readily with other molecules around them, causing aromatic organics to generally be more reactive than other organics. Examples of aromatic organics are humic acids, such as tannins. Non–aromatic (aliphatic) organics include fulvic acids and other types of less reactive organic molecules.

Given the wild nature of aromatic organics, they more readily combine with disinfectants such as chlorine, creating disinfection by–products (DBPs) such as trihalomethanes (THMs) and haloacetic acids (HAAs). Aromatic organics will also combine more easily with chemicals used for coagulation and absorption within the water and wastewater treatment process, affecting their performance. Therefore, monitoring of aromatic organics is an important aspect of any water or wastewater treatment plant operation.

UV Detection

Aromatic organics can be detected using the UV 254nm wavelength because of the strong absorption properties that these double bond organics have at that wavelength. UV 254nm measures the amount of UV light absorbed or transmitted through the water, providing an indication of the amount of natural organic matter (NOM) in the water. It is the only organic test parameter which has a specific bias towards the problematic aromatic organics.

Other organic test parameters, such as Total Organic Carbon (TOC), Dissolved Organic Carbon (DOC), Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), have their own slightly different biases. For example, DOC focuses on dissolved organics as well as some non–organic carbons, while the five–day BOD test focuses on the biologically active organics.

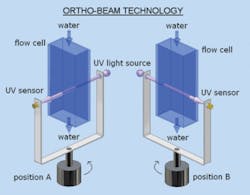

Real Tech Inc. recently introduced a new online UV 254nm organic testing system which simplifies the process for aromatic organics monitoring. The Real UVT Online monitor with its Ortho–Beam technology uses a multiple–path–length technique to solve problems that challenge conventional UV 254nm online monitors.

Ortho–Beam technology works by taking two UV 254nm measurements at 90 degree angles to each other through a rectangular quartz flow cell. This provides a measurement of the test water through two different path lengths, effectively providing continuous calibration. This allows for detection and compensation of lamp drift and fluctuations as well as quartz fouling, greatly improving accuracy and reducing maintenance.

Real time monitoring with the system provides instantaneous water quality data, which is vital for several of the most common water and wastewater treatment applications.

Process Control

Aromatic organics will consume coagulants, thereby increasing coagulant demand. The UV 254nm test parameter can be used to provide plant operators with valuable information about the amount of aromatic organics in the water or wastewater, and the ability of the coagulant to remove these organics.

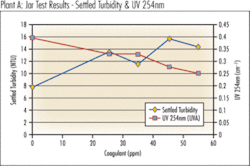

While turbidity has been used for years for process control, turbidity can remain the same even while organic levels are rising and falling. By monitoring the treated water/wastewater for UV 254nm, operators can ensure that they did not over– or under–adjust the coagulant dose.

Additionally, even if turbidity goals have already been met with a certain amount of coagulant, by monitoring UV 254nm, the operator can determine if the addition of more coagulants would further improve the removal of aromatic organics.

Diagram 2 demonstrates the importance of UV 254nm testing to determine optimal coagulant dosing for both particulate and aromatic organics. In this case, it is clear that turbidity testing alone would not provide the operator with the appropriate water quality data on which to base the optimal coagulant dose.

It is important to note that often the turbidity results from jar tests do not represent the actual turbidity results that would be seen from using coagulant in the plant. This discrepancy is due to several different factors, such as ambient temperature and floc reuse. This stresses yet another importance of testing UV 254nm.

Role of SUVA

Another water quality parameter that is becoming increasingly referenced especially for coagulation applications but also for chlorination applications is Specific UV Absorbance (SUVA). SUVA is simply UV 254nm divided by the DOC of a water sample. This allows the aromatic biased UV 254nm measurement to be normalized over the overall organic load in the water. A characterization of the aromaticity of the water independent from the general level of organics in the water can then be obtained.

In general, it is accepted that if the SUVA of the raw water is greater than 2, then UV 254nm will be the best way to determine coagulation dosing. If the SUVA is less than 2, then the turbidity of the water will likely play a role in coagulation dosing since the level of aromatic organics is relatively low. It should be noted that, in general, most surface waters contain significant amounts of aromatic organics and therefore have SUVA values of greater than 2, making UV 254nm the parameter of choice for most coagulation dosing applications.

Optimized Dosing

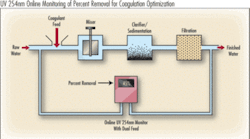

To further the benefit of UV 254nm organic monitoring for coagulation applications, online instruments can be installed before and after the coagulation process. This allows for the real time monitoring of changes to both the raw water organic load and treated water organics, providing immediate determination, control and optimization of the coagulation treatment process.

The instrumentation can also be arranged so that the chemical feed of the coagulant is automatically controlled by real time measurements providing instantaneous adjustment and therefore optimal performance of the coagulants.

The Real UVT Online monitor now provides a dual feed option, which enables one instrument to be used for two sample water feeds. By using the dual feed option the raw and treated water can be measured to provide percent removal of organics by the coagulation treatment process. The plant’s goals for effectiveness of the coagulation process, whether it be 40% or 60% removal of organics, can be continuously monitored, providing a real time understanding of the effectiveness of the coagulation process.

About the Authors:

Jodi Glover is the Business Development Manager for Real Tech Inc., based in Whitby, Ontario, Canada, a developer of organic monitoring instrumentation for the water and wastewater treatment industry, focusing on ultraviolet technology. The company website is www.realtech.ca. Tylor Hauger provides technical services for Hydor–Tech Limited, a Western Canadian coagulant Manufacture.