by Robert R. Reid, Peter V. Sevcik, and Harry C. Lorick

The West Valley Sanitation District in Santa Clara County, CA, has improved collection system operations through use of new technologies and improved business processes. The effort included evaluating work flow, determining operational improvements, developing a performance-based budget, and implementing multiple best business practices/strategies.

The program ranged from streamlining work practices to using advanced technology such as a complete Computerized Maintenance Management System (CMMS) with Geographical Information System (GIS) connectivity and Closed Circuit Television (CCTV) data to develop routine schedules, track work, and improve operations.

WVSD maintains a 435-mile sanitary sewer collection system that serves a population of approximately 120,500. The district covers a 29-square-mile area that includes four cities and unincorporated areas of Santa Clara County. The district undertook a review of maintenance operations in 2002 that included evaluation and identification of opportunities, a software selection process, and implementation in 2003 of both software and improvement opportunities.

In 2006, the district sought further improvement and developed geographic zones in the GIS to group and schedule work. The integration of the GIS with the CMMS provided valuable management information and has already shown some promising results since beginning work in the zones in 2007.

Previous Processes

The district has historically performed four different preventative maintenance cleaning activities in its collection system: balling, high velocity cleaning (HVC), power rodding, and hand rodding. Work was generated by service requests and monthly routine cleaning schedules developed through the existing maintenance system. Crews documented work performance on various reporting forms.

The primary system used for data input and generating line cleaning schedules was a FoxPro-based Computerization of Sewer Maintenance Operations (COSMO) system that was initially designed in the early 1980s. This system housed 25 years of line cleaning data. Although the system captured critical maintenance data for scheduling, it lacked flexibility to retrieve information and the capability to determine management information such as unit cost, productivity or annual work plans.

Work performance data input into COSMO included labor hours, linear feet of pipe cleaned, amount and type of debris removed, and a debris severity rating. Work production information was recorded and tracked on nine different forms based on the type of asset where the work was performed (main sewer, building sewer, structure) and the type of work performed (construction, maintenance, repair, miscellaneous). In addition, four different time tracking sheets were used by the crews (individual time sheet, daily time report, daily work report for miscellaneous work, and overtime work report for miscellaneous work).

Management information related to sewer maintenance also existed within several other databases. Many of these systems were independent of each other and made it difficult to collate information for decision-making. Activity cost information resided in the Fox Pro Accounting system, hours and accomplishment data was tracked in COSMO, sewer line inspection data was housed within the CCTV program, cost per unit data was manually calculated and filed, and activities with associated labor hours and accomplishment (LF and LBS Removed) was tracked in MS Excel. The geographical information system that mapped the collection system network resided with the engineering department, yet had not been applied to operations.

Work Process Reengineering

The district management team took on the challenge of evaluating the current operations and business practices. The goal was to enhance the positive aspects of the management process and identify opportunities where improvements in work flow and or methods could be applied. The evaluation of the current operation involved interviews with key management staff, administration support staff, the operations supervisor, and field workers. The major maintenance activities were observed in the field and work flow processes documented. This was supplemented with an analysis of the 25 years of maintenance data, review of GIS data in engineering, and operational policies, procedures, and regulations.

All of this information was compiled to establish an existing baseline of operations. Comparisons of baseline data versus benchmark information resulted in 26 recommendations for future success and included activity guidelines, increased use of high velocity cleaning, development of a performance-based budget, streamlining data collection, and updating and enhancing technology.

One goal of the project was to establish one primary database where all the information would reside and where various reports could be easily produced. The district was in a unique position of having 25 years of maintenance history data recorded by line segment in COSMO. This valuable information was retained in the new system and used for planning purposes. Further, the GIS mapping that existed in engineering was used and linked directly to the maintenance data.

The maintenance operation needed improved work management practices to help staff communicate, standardize, and document work tasks performed. Specific best management practices or performance guidelines were developed for each activity in collaboration with management and maintenance employees. The guidelines for each activity included the activity definition, mix of resources required (labor, equipment, material), a method to conduct work, and expected daily productivity based on determined work unit. This information served as a baseline and resource for all of the work planning, as well as providing the additional benefit of common terminology, a device for training, and most importantly, a tool for continuous improvement.

A detailed performance-based work plan was developed. The plan included key activities performed with associated resources (labor, equipment and material) linked to an inventory (linear feet of sewer lines), level of service (percent of inventory serviced), expected work quantity (production goals in linear feet), average daily production (expected linear feet cleaned based in a work day), anticipated crew days (work quantity divided by the average daily production), planned crew size, anticipated labor days to complete the work (crew days multiplied by the crew size), projected labor costs (including overhead), equipment, and material costs, and total cost to perform the documented activity.

Prior to this project, the maintenance staff at WVSD reported work on many different forms. These forms along with the data recording processes have been eliminated in the new system. Work is currently assigned by grouping line segments based on the time to perform the specific cleaning operation and by geographic area. Crew, equipment time and associated costs along with linear feet cleaned are captured in the new system.

Updated Software

A key task necessary to improve operations and business processes was selecting the software and technology that would best meet the needs of the district.

The district obtained a “configurable off the shelf” system to meet this objective. Explicit goals were outlined for the software needs of the district in the request for proposals. Critical needs included an asset management component, the capability to calculate a condition assessment, issue and track work orders, and the ability to manage routine and response-driven work. Other components included the ability to plan work based on defined activities, ability to develop quantifiable production-related goals, and produce outputs that would help the district manage the operation with efficiency and effectiveness.

The district received multiple responses to the request and narrowed the competition to three vendors. WVSD selected the systems software after an interview and demonstration process. The highest ranked software firm then negotiated with the district. The selected system is state-of-the-art and allows the district to plan, track, and manage routine and response-based work and use related GIS and CCTV technology.

Improvements

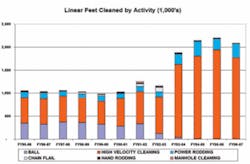

During 2002-2003, COSMO was used as the primary system for scheduling the cleaning of lines. Using this original approach resulted in 1,138,000 linear feet cleaned and included all major cleaning activities of HVC, balling, power rodding, and hand rodding.

In 2003-2004 the WVSD implemented the new approach to maintenance, which included new business processes and an improved line-cleaning schedule. Improvements included the selection of the most effective cleaning strategy, minimizing intensive manual efforts such as balling, determination of optimal crew size, and grouping of work. Power and hand rodding methods were used in limited and specific locations. The HVC application was increased using multiple cleaning heads for effective cleaning results and better ADP compared to other cleaning methods. Using this new approach resulted in 1,920,000 linear feet cleaned in the first year and 2,192,000 feet in 2005-06.

Business process improvements included pre-populating of work orders to minimize recording, production of linked location maps, the elimination of redundant work reporting forms, reduction of time reporting, elimination of multiple databases with all work data input into one primary system, documented work methods and expectations for each activity, better documentation of work, and easier retrieval of data for various work reports. Further, the system directly links GIS in a two-way capability with the maintenance system.

The condition ratings from the CCTV are completely integrated with the new maintenance system. All CCTV data can be directly retrieved from either the maintenance or GIS systems. The collected CCTV data now resides within the system. Capabilities also include the ability to display assigned routine work orders for select time periods (daily, weekly, monthly) and track the progress.

Developing Routines

The district recently grouped all sewer lines into geographic zones in an attempt to reduce travel and setup time for work crews. This was achieved by using GIS technology to determine total lengths for sewer lines and grouping them into relatively equal zones of approximately 100,000 linear feet. Twenty-four “GeoZones” were developed and scheduled to be cleaned, one per month, in order to clean the entire network within 24 months. The 25 years of historical maintenance data that was recorded and stored in the COSMO system was used to develop this systematic routine line-cleaning plan. Data included each segment of pipe with an associated upstream/downstream identifier, street location, segment length, hours worked, and the type of debris (grease, roots, gravel/sand) and the amount (measured in pounds) that was removed during the cleaning operation.

After grouping the lines geographically, cleaning cycles were established for each segment in the GIS. Historical data was analyzed to determine conservative cleaning cycles of 3, 6, 12, 18, 24, 30, and 36 months based on the severity of debris removed and the frequency of prior maintenance. An algorithm was coded that automatically determines optimal cleaning cycles based on the defined logic. These values are then able to be updated by the user in the CMMS.

To overcome the challenge of having differing routines on adjacent sewer lines, conservative cycles were applied to lines that might not need to be cleaned as frequently as neighboring lines. For example, if the decision logic determined a 24-month cycle for a single line among other lines that were on an 18-month cycle, the 18-month cycle was applied to all lines to avoid a repeat visit by maintenance crews. Sewer lines that were six inches or less in diameter were restricted to a maximum cycle length of 24 months.

Other assumptions that were used in determining cleaning cycles were that a two man crew could clean approximately 25,000 linear feet per week. This is an average production value based on over 25 years of historical data. There are also some “problem” lines that are on fixed routines and were not included in the analysis.

After determining the initial cleaning cycles, a monthly work plan was developed which calculated the amount of linear feet to be cleaned each month and the location of lines to be cleaned. The district is using one crew for routine/geographic cleaning while a second crew is used for “overdue” or emergency lines. It is estimated that all overdue lines could be cleaned in about four months; the second crew could transition to cleaning lines that are due for routine maintenance but are not included in the current month’s geographic zone.

Specific reports have also been developed that give detailed work history for individual segments and compare current cleaning cycles to cycles proposed that provide guidance for modification and optimization of cleaning. The district is now planning after calibration to develop system logic that will automatically configure and optimize this effort.

Initial Results

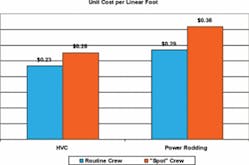

After the first few months of implementing the geographic cleaning routines, performance data was extracted from the CMMS to measure improvement. Some of the backlog work was taking longer to complete, yet noticeable differences occurred between crews. Unit costs were determined for major activities by dividing the total cost to perform the activity by the amount of work accomplished. The result is the actual cost per linear foot of main line cleaned. Crews assigned to the geographic zones showed unit costs of 15% less for High Velocity Cleaning and 21% less for Power Rodding. This is likely attributed to the reduced setup costs and travel time achieved by strategically planning the work.

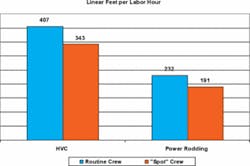

Productivity can also be measured by determining the amount of feet cleaned per labor hour. Crews assigned to geographic zones demonstrated 19% greater productivity for High Velocity Cleaning and 22% for Power Rodding.

Summary

The West Valley Sanitation District applied technology and multiple best business practices for operational improvements, established a performance-based budget, implemented new maintenance system software with GIS capabilities, and developed a systematic line cleaning schedule. This transformation led to an increase of work production, improved work processes, better documentation, and the ability to provide a process for continuous improvement. Further benefits are anticipated such as reduced travel and setup times, optimized routines for efficient cleaning frequency, and less stoppages and overflows as a result of systematic scheduling of preventative maintenance.

Overall, district customers now have more effectively cleaned lines at lower cost with fewer sewer backups or disruptions. Management has a tool to analyze and more effectively manage operations, maintenance and capital planning. The employees have received recognition for a job well done including higher compensation as result of their productivity increases.

About the Authors:

Robert R. Reid, P.E, is District Manager & Engineer for West Valley Sanitation District. He can be contacted at [email protected]. Peter V. Sevcik, P.E., was Director of Engineering & Operations for the West Valley Sanitation District and is currently with District Engineer for Nipomo Community Services District. He can be contacted at [email protected]. Harry Lorick, P.E., is Principal of Manhattan Beach, CA-based LA Consulting (www.laconsulting.com). The company provides a wide variety of planning, systems and technology services applied to public agencies and municipalities, with an emphasis on systems implementation and technical support for public works operations and maintenance. Contact Lorick at [email protected].