by Alexi Beck Gray

The Waterford Township Department of Public Works (DPW) is using its automation systems to help reduce pipeline breaks, limit energy cost increases and streamline operations of its water treatment plants, sewer pumping stations, and other facilities. Serving a community of more than 74,000 Michigan residents, the Waterford DPW manages 15 wells and 12 water treatment plants and 62 sewer pumping stations.

The department uses Opto 22 mistic and SNAP PAC hardware to monitor and control approximately 1900 I/O points in the water and sewer systems, according to Terry Biederman, Director of Public Works for Waterford Township.

"We also monitor nearly 1200 separate alarms that email DPW staff directly when a specific event occurs or to let them know that maintenance needs to be performed," he said.

One of the critical functions performed by the Opto 22 hardware is monitoring and controlling water tank levels by turning water treatment plants on and off, as necessary. When a tank reaches a programmable "on" level, the controllers start the facility and monitor and control various equipment and systems, including variable frequency drive (VFD) pumps that regulate based on both flow and pressure process variables.

"The primary design calls for the facility to turn on and be regulated based on a maximum flow set point," Biederman said. "However, as the discharge pressure at the facility reaches the preprogrammable maximum level, a PID loop in the Opto 22 controller supersedes this and automatically switches the process variable and setpoint to effectively maintain the maximum pressure until the plant shuts down or until the flow from the plant drops below 55 gpm, thereby preventing ineffective pumping."

This control scheme is designed to protect older pipes in the system that can't handle the high pressures sometimes generated by the high-service pumps at various facilities, Biederman said. The switch to pressure-based PID regulation, combined with the use of altitude valves, prevents excessive pressure and water hammer in the distribution system and has helped reduce yearly water main breaks throughout Waterford Township from 60 or more per year to around 20 per year.

Energy Savings

Since 1996, Waterford's water system has grown over 20% and simultaneously energy costs have skyrocketed. However, over this same period, the total pumping and treatment energy budget has increased by only $62,000, from $450,000 per year to $512,000 annually. The sewer pumping energy budget has seen similar efficiencies, with the energy budget increasing by only $4,000 since 1996, from $68,000 to $72,000 annually.

Control Strategies

All of the Opto 22 Programmable Automation Controllers (PACs) provide Biederman with the flexibility to design his control programs using flowcharts, which are easier and more intuitive for the DPW staff to program and understand. The DPW also uses the company's software connectivity tools to create the communications and graphics interfaces needed to deliver data and alarm messages from facilities.

For example, at some of the water facilities, pressure filters are fitted with temperature sensors to monitor tank water temperatures. If temperatures drop below 38 degrees, a warning email is sent to DPW staff.

"Furthermore, when tank water temperatures reach 35 degrees, the control program was designed to automatically look for freeboard in the distribution system tanks and turn the facility on to move the water, thus keeping it from freezing and rupturing the pressure filter," Biederman said. "If the distribution system tanks do not have the freeboard to pump the water into the system, a facility backwash process is initiated to move the water."

The 22 control system addresses other operational issues as well. At a large sewer pumping station, grease and other debris in the wetwell were clogging pumps causing numerous difficulties. To solve this, DPW staff and a Waterford Township consultant designed a wetwell backflush process and wrote a program to have the control system redirect all station flow through a Vaughn Chopper Pump that "purees" the material in the wetwell. After 10 minutes, a second pump activates and pumps the material out of the wetwell while the puree process continues. Then, after 10 more minutes the program ends and the station automatically returns to normal operation.

Program Conversion

Biederman used PAC Project Professional to convert many programs he had designed for his older mistic controllers on a "one-for-one" basis. The conversion took place instantly (upon opening the old strategy with the new software) and required very minimal editing.

"We appreciate the fact that Opto 22 mistic control programs can integrate and run on the new SNAP PAC controllers," Biederman said. "It's allowed us to maximize our investment by not having to upgrade as new hardware was introduced by Opto 22."

"When it comes to the older hardware, our support is always there and we keep it simple," said Tom Edwards, Senior Technical Advisor at Opto 22. "Due to purposefully engineered backward compatibility, we don't have to force customers to replace their older hardware. It's up to them. SNAP PAC controllers used with PAC Project Pro can talk to any existing mistic I/O without any problems."

PAC Project Professional also includes OptoDataLink, an enterprise connectivity software application that allows SNAP PAC users to create a bi-directional data transfer link between their PACs and enterprise databases. Users can consolidate and publish data from SNAP PAC controllers and brains to Microsoft® SQL Server, Microsoft Access, and MySQL, among others.

Biederman used Intellution® software to develop the human machine interfaces for the control system at the Waterford DPW's central office but uses Opto 22's FactoryFloor and PAC Display software HMI development software at the water treatment facilities and major sewer pumping stations.

"For HMI development, PAC Display has many of the features of the more expensive Intellution and the symbol factory offered is equal if not better," he said. Support for the Opto software is also free of charge.

Another advanced functionality of the DPW has been the deployment of broadband wireless capabilities and a Geographic Information System (GIS) with integrated Computer Maintenance Management System (CMMS) and electronic document management. DPW staff can view electronic maps and graphical representations of the township's water and sewer infrastructure and — by clicking on a pipe, valve, or pumping station — can view work order histories, engineering documents, and other relevant information.

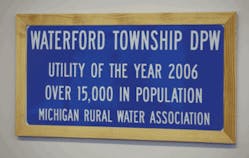

The Waterford DPW's advanced monitoring capabilities and very high levels of automation have gained a measure of notoriety across the country. More than 20 consultants and other municipalities from all over the US and Canada visit the DPW each year to tour its SCADA and other technology deployments.

"We use technology to solve problems and to operate more cost effectively and efficiently," Biederman said. "There's always a continuing evolution of technology and it's just good business sense to leverage the functionality, communications, and interoperability that our Opto 22 control system, GIS, and communications infrastructure provides."

About the Author: As Opto 22's Director of Training, Alexi Beck Gray, M.S.M.E., creates the curriculum for the company's product training classes and co-teaches classes held at the company's headquarters. She also develops and presents the company's online tutorials and instructional videos. Gray holds a Bachelor's of Science degree in Mechanical Engineering from Pennsylvania State University and a Master's degree in Mechanical Engineering from the University of California, Irvine.Circle No. 269 on Reader Service Card