Johnstown, CO, is a rapidly growing community located between Denver and Fort Collins. A few years ago its wastewater treatment system was reaching maximum loading and experiencing difficulties in meeting the allowable permitted Biochemical Oxygen Demand (BOD) levels in its effluent. Staff also was concerned about meeting the allowable permitted Total Suspended Solids (TSS) in the plant effluent to the Little Thompson River.

The average flow rate to the wastewater treatment plant is 400,000 gallons per day and the treatment scheme consists of a three-cell pond system. The first two ponds contain aeration and the third pond is used for settling the suspended solids. Plant effluent averages 27 mg/L of BOD (but with excursions goes over the allowable limit), and 35 mg/L of TSS (but with excursions goes over the allowable limit in the summer when algae grows in the final pond).

Pilot Study

Johnstown invited, ITT Leopold to conduct a pilot study using the company's Clari-DAF® (Dissolved Air Flotation) System. The study was designed to determine the system's performance, particularly when algae were present in the final pond. The goals were to determine design criteria with respect to loading, recycle rate, sludge quality and quantity, chemical consumption, and BOD & TSS effluent quality.

The influent to the pilot unit was drawn directly from the third pond using a submersible pump. Jar tests established that the optimum starting chemical dosage for the pilot test would be 100 mg/L of alum and 0.25 mg/L of poly DADMAC.

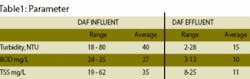

The results of the 3-week pilot test are shown in Table 1.

The Clari-DAF loading rate was varied from 4 – 8 gpm/ft2. Whether the unit was fed at the low rate or high rate, the effluent remained the same good quality. The sludge produced contained 2 – 4 % dry solids and the production volume averaged 0.4 % of influent flow. A sludge drying bed test conducted during the pilot test produced cake solids of 6.88% after only 24 hours of operation.

Pre & Post DAF Installation

Based on the pilot performance, a Leopold Clari-DAF system was purchased by the town, installed and commissioned in February 2004.

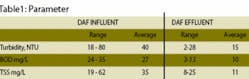

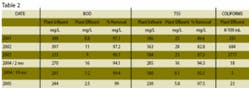

The town also added additional aeration to the first two ponds, and a Moving Bed Biofilm Reactor (MBBR) nitrification process to convert ammonia to nitrate prior to sending the wastewater to the Clari-DAF unit. Annual results for BOD, TSS and coliforms for five years are as shown in Table 2 (Clari-DAF system performance in 2004-2005), while Table 3 contains the highest average recorded months for BOD, TSS, and coliforms for each year (Clari-DAF system performance in 2004-2005).

Gaining operational experience since start-up, the plant personnel have reduced the alum dosage from 100 mg/L to 60 mg/L and eliminated the cationic poly DADMAC chemical feed entirely. This has reduced operating chemical cost, as well as changed the nature of the sludge that was removed from the surface of the flotation cell. The sludge thickness was reduced permitting more effective flushing of the sludge from the hopper.

In addition, the normal algae blooms typically found in the third pond have had no affect on plant discharge. A bonus benefit has been noted with annual effluent coliform counts now averaging less than 100 CFU/100 ml vs. pre-DAF effluent coliform counts of 5,000 CFU/100 ml.

The Leopold system processes 400,000 gallons of wastewater per day, but is designed at a higher loading rate to operate at flows up to 750,000 gallons per day. Its location in the treatment plant allows for installation of a duplicate Clari-DAF system, which would double plant capacity to 1.5 mgd.