The Northern Rockies Region of northeastern British Columbia is blessed with a significant wealth and diversity of natural resources, heritage and cultural attributes. Over the last four decades, the region has experienced its up and down cycles due to the growth and decline of numerous resources and development activities. There have been interesting development proposals such as the Horn River Shale Gas Development, a working partnership that would link the Northern Rockies Regional Municipality, Fort Nelson and First Nation communities with the oil and gas industry, and provincial government agencies.

In support of this partnership, the Northern Rockies Regional Municipality water and wastewater treatment facilities produce the treated water needed to run operations at oil and gas projects and forest and mining activities in addition to serving its population of about 5,000 residents. The utility also provides a bulk water station that furnishes water for those not on municipal water and to the trucks that transport water to operations in the oil and gas patch, such as for fracking.

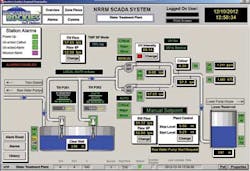

"Fort Nelson has a fully automated bulk water station, which delivers an average of 400 cubic meters of treated water for residential and industrial usage daily," said Michael Ferguson, Electrical and Automation Specialist for the Northern Rockies Regional Municipality. "This station is fully integrated into the municipalities' SCADA system, which facilitates monitoring of flow totalization, alarming of heat trace and boiler systems, as well as trending chlorine residual levels in the water being dispensed, etc."

According to Ferguson, the municipality recently moved from Siemens' now-legacy product FactoryLink, to PcVue for use with its SCADA system. Fort Nelson's SCADA system includes 22 Motorola ACE RTUs at various pump and lift stations, which communicate over a 900 MHz IP Radio network.

"We have two Motorola IP Gateways (of the Ace3600 platform), which are primary and redundantly configured. The IP Gateways are the interposing link between the network of field RTUs and the managing Servers (also redundantly configured). Our servers are located at the municipality's water treatment plant."

Through the help of their value-added reseller (VAR), CTH Systems, the municipality chose the hardware-independent PcVue SCADA package that integrates seamlessly with CTH Systems' IM-SCADA™, an advanced multiprotocol measurement and communication software.

"CTH Systems provided the key component (the IM-SCADA Driver Software) that allowed for a quick transition to PcVue," Ferguson said.

CTH Systems used PcVue's SCADA application builder tool called Smart Generator to port Northern Rockies' applications to a more secure and robust SCADA architecture. PcVue and CTH's IM-SCADA software sit on these servers as well as the historical databases.

This Fort Nelson facility also happens to be British Columbia's first and only "Resource Municipality" to service the oil and gas industry, local residents and businesses. It covers more than 10 percent of the province and includes the majority of the vast Horn River Shale Gas Development. Ferguson manages the electrical systems, process control, automation and communication component of the municipality's water and wastewater infrastructure.

Currently Fort Nelson's SCADA system manages about 8,000 tags. With ongoing capital projects such as a new UV disinfection station to treat wastewater effluent, the system is poised for growth.

Fort Nelson's water treatment process begins by drawing raw water from the Muskwa River, downstream of the Alaska Highway bridge crossing. There are several critical processes involved in filling the municipality's raw water reservoirs. The initial raw water pumping requires multi-stage pumping with PID control to overcome tremendous head pressure and control the variable flow rates.

"The process of treating water is not a static process for us. Process variables such as turbidity, color, and organics are influenced from things such as weather events. For instance, we once experienced a mudslide where the river we pump raw water from was impacted," said Ferguson.

Report, Trend Generation

CTH has provided engineering support to allow the municipality to export data in the form of .CSV files to a report and trend generation service called FlowWorks. FlowWorks conditions incoming data with various algorithms such as time-weighted averaging, allowing non-operations personnel to view trends and generate reports. Additionally, CTH has provided real-time and historical trending as an inherent feature of the IM-SCADA driver. This feature presents the data needed to make decisions on how to best optimize operations.

As Ferguson further works to develop the potential of Fort Nelson's SCADA system, he plans to integrate PcVue with other management applications such as their work order system.

"The goal of our responsible management and preventative maintenance philosophy is to bundle systems like SCADA, PDAs and work order application software together. To responsibly operate and maintain a productive multi-million dollar infrastructure such as ours, it requires that we combine the use of technologies, the efforts of personnel, and a forward thinking approach," Ferguson said.

Currently Ferguson is working to have automatically generated work orders based on pump run-times and pressure changes that indicate wearing seals, etc. In addition, he would like to have the ability to view system data such as alarms, pressure, and levels from a mobile device such as an iPhone, which is now possible with the use of the latest version of the IM-SCADA driver.

"Having the freedom to access real-time system data from a mobile phone is a welcomed feature, which will get a lot of use from operators at NRRM," Ferguson said.

Currently PcVue is configured to have one mimic per site along with configured pop-up windows so that if additional details are needed on a pump house or certain critical values, an operator can simply click on the icon to open a pop up window to provide the information needed.

"We have multiple mimics built in PcVue that facilitate the various exchanges between the operator and host. Graphically the mimics are the same as what would have been in FactoryLink," Ferguson said.

PcVue will contribute to Fort Nelson's effort to reduce reactionary repairs and unexpected equipment replacement. This is achievable by tailoring alarm and reporting functionality to expose issues at an early stage. The use of a fully automated SCADA system is essential in downtime prevention in water and wastewater services provided by this growing municipality.

WaterWorld Articles Archives