By Martyn Easton

Since the beginning of civilization, managing wastewater has always been a prominent issue. The ancient Greeks had flush-toilets as early as 1500 BC, and the sewer is widely considered one of the greatest accomplishments of the Roman Empire. But as recently as the late 1940s, most sewage went untreated before being dumped into rivers, harbors and lakes - even in major U.S. cities. As environmental regulation and standards evolve, plants worldwide will be faced with improving their technology to meet the demands of growing populations and expanding industrial activity.

DCS, PLC, SCADA

Wastewater treatment plants rely on the coordination of many moving parts to maintain successful operation. Determining which pumps or valves are used is based on the status of water during the treatment process. Traditionally, distributed control systems (DCS) have synchronized the varying wastewater in-flow rate with the rest of the plant. Although the recent introduction of optical fiber cabling to the DCS infrastructure has made it more reliable, the need for even more effective and affordable solutions is expanding.

According to a March 2013 research study published by the ARC Advisory Group, water treatment plants will continue to experience a high demand for automation technology over the next 20 years. Enter the computer: Computers are essential to making a number of control decisions across water treatment facilities. But in this environment, computers are called programmable logic controllers (PLC).

PLCs differ from an average computer in that they are designed to handle hundreds of I/O signals. Inputs are generated from sensors, such as valve open/closed status, water levels, flow meters, temperature, pressure, chemical concentrations, and more. Outputs connect to equipment actuators that start and stop pumps, valves, gates, and motors. The PLC is programmed to analyze the status of all the inputs, make decisions about what to do and send corresponding output signals.

PLCs are ruggedized for field-use to maintain reliable operation in harsh conditions, such as dust, moisture, vibration, heat, cold, and electrical interference. Their logic programs are designed to be robust and highly-stable and are intended for real-time operation since output results are produced in response to input conditions.

As critical systems become more complex, the need to interconnect PLCs in order to communicate with each other becomes increasingly important. A fully-integrated and centralized system is called a supervisory control and data acquisition system (SCADA). Likewise, a variety of proprietary communications protocols have been developed by leaders in automation and process control. These have developed into more interoperable protocols, such as Foundation Fieldbus and Process Field Bus (ProfiBus). And Industrial Ethernet (IE) is quickly catching on. A variant of the ubiquitous IEEE Ethernet for LAN applications IE offers fuller interoperability and leverages larger economies of scale.

Fiber Applications in Wastewater Treatment

As wastewater treatment plants are built, expanded and upgraded, optical fiber is becoming an essential part of the communications infrastructure. The main use of optical fiber in a wastewater treatment plant is for the interconnection of the distributed control units back to a central control room. In a system deployed in Montreal, Canada, for example, fiber connects switches at 13 remote control locations. Each one is dual-connected with redundant cable routes looping 900 meters around the facility.

At another facility in Washington, D.C., in addition to the networking of the distributed controllers to the central and area control centers, there are 60 process cameras that connect back to the center to visually monitor critical operations in unattended areas. The plant-wide fire alarm system is also connected back to the center.

Perimeter control and security is also a growing concern. It is unpleasant enough when residents' toilets back up, let alone an entire city plant backing up due to the misdeeds of trespassers.

Fiber Count and Type

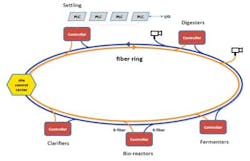

Sizing the fiber plant and choosing the number and type of fibers is a crucial decision, given that it is expensive and disruptive to add additional capacity at a later time. The ring architecture (see Fig. 1) is used to provide fault tolerance and redundancy with fibers feeding each distributed control location from two directions. Bandwidth demands are not high in these applications, but the reach for a link can be several kilometers in length for the larger facilities. As such, either multimode fiber or standard G.652 single-mode fiber will suffice.

For fiber count, six fibers are generally sufficient for each distributed control unit location from each direction. This provides for two live circuits and one spare set. An efficient solution is to run a high-fiber count cable in a loop through multiple control locations and mid-span slice it into six fibers that can then run in each direction. A 72-fiber cable can serve 12 locations. Serving home runs for camera and other applications will require more fibers. The overall cable plant must be designed with end locations, available pathways, redundant routing, and future expansion needs in mind.

Cable Type

Cable choice is particularly important because wastewater treatment plants present a uniquely harsh environment. In addition to the usual exposure to weather changes, there is also the potential exposure to caustic chemicals and heavy equipment. Further, water should never be overlooked in any outdoor application, and certainly not in a wastewater treatment plant. As with many industrial facilities, there are multiple high-voltage power cables used to maintain operation, thus it is ideal to use dielectric fiber cable construction to eliminate grounding and coupling concerns.

Where extra protection is desired, corrugated steel tape armoring is the usual solution and can be used with the appropriate grounding of the armor; however, this contradicts an all-dielectric solution. Double-jacketed dielectric cables with fiber-glass armoring are also available. Either way, a standard loose tube construction is most appropriate to protect the fibers from the environment.

Cable Termination

Industry-standard techniques are used for the termination of the cables and, in part, to depend on the capabilities of the installer. Common options are fusion splicing or no-epoxy, no-polish (NENP) connectors. These connectors are field-terminated on the fibers after a buffer-tube fan-out kit is installed. It is a quick and reliable choice, especially for low fiber count cables. Further, NENP connectors can be easily installed in confined spaces with simple hand tools in less than two minutes and are tested to be highly reliable and stable across the wide temperature range of an outside installation.

The choice of connector type, whether spliced pigtails or field installable connectors, presents some options. A good practice is to standardize one type for all cable terminations and to make this choice match the primary connector interface required for the network electronics - this will likely result in the SC or LC type. Both are push-pull connectors widely used in the industry. The LC is smaller, thus offering higher connector density. This is rarely a limiting factor in this environment, but the LC is increasingly the interface on the electronics.

The choice of termination housing to store, manage and protect the connectors is important. The main issue is protection from the environment, dust, dirt, and potential impact. The distributed control units may be located in a building or outside in a weather-sealed cabinet where DIN-rail mounting is common. Process control cabinets are often not set up nor have room for fiber cable terminations. In this case, it is common to place separate fiber termination housing adjacent to the cabinet. At the central control center, indoor rack-mount termination housings are appropriate.

Standard Design Practices

While the overall design and layout of an optical fiber cabling infrastructure is completely site-specific, standard information and design practices can help municipalities effectively anticipate the needs of their infrastructure effectively and ensure that everything runs efficiently, safely and securely - today and tomorrow.

- Add it up front - Size the fiber plant to accommodate current and future known applications, and then add some capacity for unknown additions.

- Account for unlikely conditions - Consider the site topology and obstacles in order to select a cable type that will provide lasting protection for the fibers in all conditions.

- Expect the unexpected - Build redundancy and fault tolerance into the system.

- Plan ahead - Many sites are built in phases, so consider the prospect for growth and needs due to site expansion.

- Choose wisely - Most cabling problems occur at the cable ends, so select appropriate termination enclosures that will adequately organize and protect the fiber terminations.

About the Author: Martyn Easton currently serves as market development manager for the Corning Optical Communications Private Networks market. He is responsible for identifying and developing initiatives for new product solutions and market segments within the premises cabling environment. Martyn holds three patents for indoor cable products and has authored numerous technical publications. He received a Bachelor of Arts degree in engineering from Cambridge University and a Master of Business Administration from the University of North Carolina at Chapel Hill.