By Jeanne Mensingh and Colin Thurston

Wastewater treatment, like other industries that rely heavily on dynamic sampling programs, has had to implement far more rigorous testing in recent years, and the challenges facing treatment facilities haven't necessarily come from stricter regulations or standards but from a fundamental change in the wastewater stream itself.

The wastewater stream is more contaminated than ever, with more diverse and exotic compounds (e.g., overprescribed pharmaceuticals) that ultimately place a heavier burden on treatment facilities to ensure their output is safe. As such, providers must dramatically increase their sample load and the overall number and complexity of tests simply to remain in compliance with preexisting regulations.

How can these already overtaxed sampling programs increase throughput without financially straining the communities or organizations they serve? Further, how can they maintain public health in the face of unprecedented wastewater contamination? One answer is data management and using laboratory information management systems (LIMS) to do more with less. Automating tests and eliminating manual procedures through LIMS allows wastewater treatment systems to shoulder increased testing loads while actually improving efficiency and testing efficacy.

Altering the Waste Stream

We know that new contaminants are taxing the wastewater stream, but why are they such a problem? To answer that question, we first need to explore what happens to wastewater. While there are many final destinations for treated wastewater, it has a consistent (and obvious) source, and sampling begins early.

Water treatment providers dispatch technicians to upstream sample wells across their regions to test wastewater before it reaches a treatment facility. In the past, test results were handwritten on paper, and the data slowly made its way into a hard copy report. With LIMS, however, technicians use mobile devices to record bar codes, readings and coordinates, allowing real-time (and more accurate) sample reporting and aggregation. Downstream plants can use this data to prepare for treatment ahead of time, expediting the process.

The wastewater treatment process, from primary and secondary treatment to disinfection, is complex and involves multiple steps. Rigorous testing is performed to ensure that any water exiting a treatment facility - for any eventual use - is safe. Technicians use spectrometry, chromatography and wet chemistry to analyze wastewater for harmful contaminants such as heavy metals and antibiotics.

Antibiotics, which are shown to be overprescribed by recent reports from the Centers for Disease Control, among others, enter the wastewater stream through human waste and improper disposal of leftover pharmaceuticals into drains and toilets. Over time, this practice can lead to the emergence of antibiotic-resistant bacteria that could ultimately impact humans as the treated effluent travels beyond the facility.

Testing for and eliminating antibiotics and drug-resistant bacteria is an increasingly important function of water treatment facilities. Knowing the precise levels of bacteria in water undergoing treatment is essential to determining how much chlorine to add. Similarly, wastewater contaminated with heavy metals such as lead must undergo special treatment as an extra precaution.

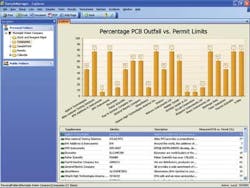

Accordingly, the complex process of determining which treatment options to use is greatly simplified using LIMS. Because the platform integrates with the instruments used to track contaminant levels as wastewater is treated, LIMS can help technicians identify trends that improve treatment performance and efficiency. This data is also critical for regulatory compliance, auditing and reporting purposes, and it ultimately plays an important role in determining where treated wastewater is put to use.

Where Does Wastewater End Up?

Although wastewater is no longer potable, it has myriad productive uses. Some of the water ends up in lakes, rivers or oceans, where it must be safe enough to avoid posing a public health risk, either through human contact or wildlife contamination. Other destinations for reclaimed water include street cleaning, plumbing, landscaping irrigation, and even crop watering. This last use illustrates how important proper wastewater treatment is to public health and safety. This is precisely why the broader-reaching capabilities afforded by LIMS are growing important for wastewater treatment providers.

Sadly, analytical instruments alone can't provide the measure of protection consumers have come to expect. Last spring, for example, the U.S. Food and Drug Administration identified commercially-available rice imported from China and Taiwan containing 120 times the acceptable level of lead. Investigation revealed that producers had watered the rice with improperly-treated wastewater that contained raw industrial effluent. Would a better system of data capture and reporting have alerted officials to the problem prior to shipment of the rice?

LIMS are the key to addressing growing challenges with monitoring and compliance, and they have become more necessary and more prevalent for water treatment facilities. Paper-based systems can no longer handle the volume of sample throughput, data management and reporting complexity in an effective manner. As such, LIMS schedule and hold sampling plans, which are then used to generate a collection run for each sampler. This run defines where samples must be taken, what sample bottles must be collected and what onsite tests must be performed.

Water treatment centers need to optimize the utilization of their staff and equipment to improve efficiency and productivity. Minimizing time-consuming and potentially error-prone manual processes is a key weapon in the lab manager's arsenal. LIMS allow for considerable reductions of time-consuming manual processes and administrative overhead in the lab. Likewise, lab operating costs are especially diminished by LIMS that feature built-in functionality specific for water and environmental laboratory workflows.

While LIMS do not ensure more accurate or frequent testing, they do provide a discipline that enables water treatment systems to be more proactive, responsive and compliant - all of which are precursors to better public safety. If upstream contamination does occur, for example, a paperless lab enabled by LIMS is much more likely to detect and help mitigate the issue in a rapid manner before it impacts the treatment system. LIMS also store information about the origins of contamination and where wastewater is released, enabling facilities to identify problems in near real-time, trace them to the source and ensure that similar problems don't occur in the future.

Conclusion

The changing dynamics of wastewater treatment are taxing many facilities, and more rigorous sampling is seen as the best course of action. As sampling throughput increases, the wastewater treatment industry - like other industries - is looking to better data aggregation and applications to lead the way forward. LIMS can transform data management from a limiting factor to a driving force for business success by improving accuracy, ensuring compliance and helping managers identify trends. It is unlikely we will see fewer contaminants such as antibiotics enter the wastewater stream, so it is incumbent on the industry to shift priorities and adapt - and LIMS are certainly an important part of that shift.

About the Authors: Jeanne Mensingh is NELAP Assessor and President of Labtopia Solutions, and Colin Thurston is Project Director of Informatics, Thermo Fisher Scientific.