Automation Aids Water Utilities' Asset Management Abilities

By Bradley Williams

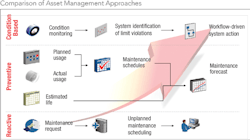

Historically, water utilities have relied on traditional asset maintenance processes, which are typically cyclical in nature and reliant on truck rolls. This approach has led to higher costs and risk, as work isn't always correctly prioritized, warranties may be compromised, security issues aren't quickly addressed, and device failures occur that could have been prevented given more timely maintenance.

Further, many municipal water distribution utilities have been asked to use the same asset management applications as other local government departments, despite the fact that water utility assets are far greater in number, complexity and criticality than those in other agencies.

As infrastructure and assets age, a utility's asset maintenance workload continues to increase, unlike the resources available with which to do the work. That said, "making do" and employing manual processes can have an adverse effect on operational efficiency, performance and the water utility's bottom line. Automation, however, is redefining and transforming the ways in which utilities carry out asset management tasks.

An Automated Utility Maintenance Shop

In today's utility operations, increasing operational efficiency often starts with improving asset management processes, thereby creating opportunities to maximize the effectiveness of operations and maintenance spending. This is an important step-change, moving the utility to a more proactive and predictive approach to maintenance.

Asset management and maintenance have always been a balancing act between efficiency (the cost of providing the equipment) and effectiveness (the availability and efficiency of the equipment). The essence of most utility maintenance strategies, then, is to optimize the availability of the assets against the cost constraints of providing that availability.

Automation is playing an ever-growing role here. Already common in plant process-control systems, automation is also being increasingly used in field operations, particularly with the growth of lower-cost and more functional sensors and controls combined with a broad range of low-cost telecommunications alternatives to send and receive information from these devices.

Advanced asset risk analytics leverage these new automation sensors and controls to enable real-time analysis of flow, pressure and quality, as well as correlation of advanced metering to provide immediate prescriptive maintenance work requests. This real-time automation of sensor data can mitigate a problem before it becomes a more major issue and costly repair.

As automation is applied to smart sensor and control devices along the utility's infrastructure, it is much easier to ensure a right work/right time approach. However, the maintenance lifecycle of the new smart devices must also be considered for new field maintenance processes such as device configuration and firmware updates.

Automated device management processes can reduce the need to put more people in the field. In fact, operational device management -- an essential part of an effective 21st-century work and asset management solution -- can serve as an automated lifecycle management and maintenance shop, analyzing data in real time to quickly identify and proactively adjust, update and repair security, performance and compatibility issues as needed.

This automation, in turn, provides the added bonus of reducing field crew safety issues as well as significantly reducing cost and time of repairs. Automated smart device maintenance and management also minimizes environmental impact by reducing truck emissions (because of the lower number of truck rolls necessary) and equipment failures.

Eliminating Manual Processes

Many water utilities still use a heavily manual asset inspection and data capture process upon which to build their asset management strategy. However, real-time, automated asset optimization can only occur when process inefficiencies and errors associated with manual processes can be eliminated. An automated approach to this process -- incorporating best practices -- more effectively scores asset condition by taking into account assessment weighting, confidence factors and asset class statistics.

In some cases, device data can be automatically collected by the mobile device or tablet that the crew is already using for work scheduling and asset inspections. The tablet proximity to the smart sensors and controls can automatically start the process to collect its data on the tablet and, once connected, upload to the advanced asset management and analytics systems for immediate processing.

This is already common in consumer home automation and automotive machine-to-machine applications of the Internet of Things (IoT). For example, consumer applications in use today utilize smartphones and tablets to control home temperature/comfort, audio, visual, and energy management. Further, many young new hires already use these consumer IoT applications and are delighted to leverage similar technologies to optimize their work.

A strong utility work and asset management program can automatically store and normalize the asset condition capture on an ongoing basis so that it can be recalled as needed. This allows a utility to have a system to generate a score for each assessment, not just a lot of raw data, providing the utility with a more accurate view of asset health in real time, as well as the ability to use that information to achieve process improvement and business goals.

Incorporating Best Practices

Water utilities dedicate substantial revenue and personnel to assets, all of which must be installed, tracked, maintained, repaired, and replaced in a proactive manner to maximize operational efficiency. Using best practices, they can reduce total asset-related costs and increase asset reliability, both of which are key to ensuring water quality and affordability. There are many ways this can be done:

- By identifying and automating process efficiencies (e.g., using planning and maintenance job templates and automated work-order schedules), a utility can eliminate manual process errors, increase workforce efficiency and maximize the value of work and assets while reducing expenses.

- By automating objective data analysis as a core business process, water utilities can gain greater actionable insight than was previously gleaned from subjective or observed assessment and intuition. Using predictive and algorithm-based analytics, utilities can capture information from numerous and seemingly disparate data sets, consolidate it and then run it through multiple analytical models. These models can identify for correction anomalies or causal linkages that typically aren't evident but often lead to increased risk.

- As experienced employees continue to age out of the workforce, using a knowledge transfer mechanism such as a job template ensures utilities can retain their retiring employees' knowledge and expertise. By automating the capture of details such as labor estimates, equipment used, safety information, maintenance history, job process, and notes, these templates become a formal repository of knowledge on what works -- and what doesn't -- for any task.

- Operationalizing new assets has historically been a sometimes lengthy and cumbersome process. Automated data migration from construction to operation, however, can drive down the time and error associated with this process.

Adopting best practices for maintenance and improved knowledge management through the automation of specific tasks such as those listed above effectively increases operational efficiency and maximizes each asset's value to the utility, its customers and regulators, while at the same time substantially decreasing the time and costs associated with those previously manual tasks.

The Asset Management Fulcrum

Through a combination of automation and data intelligence, a utility can effectively maximize its work capacity and productivity, resulting in the completion of more predictive maintenance work. This proactive, condition-based management approach creates an optimal balance of compliance, reliability, safety, work efficiency, and cost-to-operate for each asset.

For water service providers, in particular, being able to remove data visibility limitations on buried assets -- for which they have limited baseline inspection data -- enables them to improve upgrade investment and maintenance work decisions going forward.

Optimizing asset value and reliability in an era of aging infrastructure, changing weather patterns and tighter operating constraints are mission-critical goals for water utilities today. They are increasingly challenged by the need to optimize asset performance at a lower cost -- effectively doing more with less -- while continuing to balance efficiency and effectiveness in asset maintenance. Increased automation, combined with objective data analysis, is the essential fulcrum upon which an effective work and asset management strategy rests.

About the Author: Bradley Williams is vice president of Oracle Utilities Global Business Unit's Industry Strategy, responsible for Oracle's smart grid strategy as well as utility applications for outage management, distribution management, mobile workforce management, work and asset management, and load analysis.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles