By Ron Fall

The aging infrastructure that transports potable water to our homes and businesses in the U.S. is in a state of disrepair, with about 240,000 water main breaks occurring every year. In some areas of the country, the pipes and systems for transporting water have been in use for over 100 years.1 The Environmental Protection Agency (EPA) estimates the cost of upgrading this vital infrastructure to be about $335 billion over the next 20 years; this issue will, therefore, take a long time to fully address.2 These facts have led the American Society of Civil Engineers in their "2013 Report Card on Infrastructure" to give the current state of the U.S. water distribution system infrastructure for drinking water a "D" rating -- further confirming this system is in poor condition and needs repair.

In addition, the EPA's "Sanitary Sewer Overflow and Peak Flow" report states that up to 75,000 occurrences of sanitary sewer overflow may be taking place each year. When we consider the number of identified water line breakages each year, combined with the potential sources for contamination such as sewer overflows and/or flooding conditions, the potential for waterborne illnesses such as cryptosporidiosis ("crypto") or Giardia is a major concern. We should also keep in mind that when the groundwater surrounding a damaged pipe, which could contain harmful waterborne pathogens, is drawn into the potable water process stream, that potable water can no longer be considered treated or fully safe.

The key concern is what contamination may have entered our water supply from the time it left the water processing facility to the time it is used in our homes or businesses. As such, the EPA implemented the "Surface Water Treatment Rule" to help address the pathogens within our potable water supply. This rule requires public water systems to have a treatment method in place that can reduce the levels of Giardia by a minimum of 99.9 percent and other viruses by 99.99 percent.3

Furthermore, groundwater sources must be monitored for microbial contamination or provided with a similar level of microbial performance. Regulatory agencies that oversee our water supplies must provide documentation regarding the quality of the water to ensure it meets the Surface Water Treatment Rule for the water leaving the water-processing facilities. They cannot, however, guarantee the water quality as it enters our homes and businesses because contamination can occur between the time the potable water supply is treated and the time the water reaches the point of use. Because of this uncertainty, adding a water-treatment unit prior to point-of-use access provides a final barrier of protection from these unknown factors, especially for microbial contaminants that can cause serious health issues.

Point-of-Use Treatment Systems

Today, there are various water disinfection treatments available that remove microbes and pathogens from our water supplies prior to use. The EPA, in its document "Drinking Water Treatment," states that ozone and ultraviolet disinfection are effective in relatively clean water sources.4 The reports also states that adding chemical treatments such as chlorines, chloramines and chlorine dioxide to the water can be a very effective treatment. However, the Agency does point out that certain microbial pathogens, such as Cryptosporidium, are highly resistant to traditional disinfection practices. Also, disinfectants themselves can react with naturally-occurring materials in the water to form disinfection byproducts such as trihalomethane (THM) or haloacetic acids (HAA), which pose health risks and are known carcinogens. The safe drinking water regulations indicate that a residual of chlorine must be present at the end of the distribution lines; however, this task is daunting to achieve by any water utility on a day-by-day basis. If free available chlorine is not present at the point it enters your facility, the microbial safety of this water is suspect.

How to Eliminate Dangerous Microbes

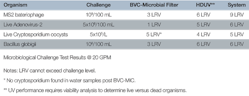

A new, green approach to water treatment has been developed by Parker Hannifin Corporation's Domnick Hunter Process Filtration Division to address the growing risks for microbial contamination within water processing applications. The Parker BVC (bacteria, virus and cyst) system is a multi-barrier water treatment system that combines a pre-filtration unit with a charged membrane filter, with an ultraviolet treatment as the final barrier within the treatment train. The BVC is developed specifically for microbiological disinfection and minimizes or eliminates the need for chemical treatments within the water treatment process. Testing by a third-party laboratory shows that the system is capable of providing a minimal of 4 log reduction value (LRV) for a wide variety of pathogens including Giardia, cysts, adenovirus, and other viruses, as indicated in Table 1.

This table is a summary of the test results from the third-party evaluation, which reports the effectiveness of the individual components along with the complete system:

Point-of-Use Filtration Protects the Public

Have you visited an amusement park during a hot summer day where water misters were being used to keep you cool? Perhaps you've been in a grocery store when water misters were spraying the vegetables. You may not realize it, but breathing in those water droplets from mister and fogging systems could potentially expose you to harmful airborne pathogens. This is especially true if the water sources of those systems are contaminated and a microbial treatment has not been conducted on the water process stream prior to its release into the air.

A two-year study by the EPA reported that 47 percent of 272 tap water samples taken from 68 different locations tested positive for Legionella pneumophila.5 These findings reinforce the potential health risks of potable water that has not been treated at its point of use by an effective treatment system. In addition, the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE) is currently developing Standard 188P: "Prevention of Legionellosis Associated with Buildings Waste Systems."6 This standard will help establish water treatment methods that facilities can use to protect against the occurrence of dangerous waterborne illnesses such as Legionnaires' disease, Salmonella, Escherichia (E. coli), and others, some of which can be fatal.

Parker Hannifin's BVC system is a multi-barrier treatment system that provides a minimum 4 LRV reduction of bacteria, viruses and protozoan cysts. It was developed to provide facilities with a final barrier of protection from any microbial contaminants that may be present. Installation of this type of equipment will provide added protection for your customers, employees, brand reputation, and/or family. WW

About the Author: Ron Fall is the senior principal engineer for Parker Hannifin Corporation – a domnick hunter Process Filtration Division.

References

1. "2013 Report Card on American Infrastructure," American Society of Civil Engineers (ASCE), www.infrastructurereportcard.org/grades.

2. "Sanitary Sewer Overflows and Peak," Environmental Protection Agency, http://water.epa.gov/polwaste/npdes/sso/index.cfm.

3. "Ground Water Rule," Environmental Protection Agency, http://water.epa.gov/lawsregs/rulesregs/sdwa/gwr/basicinformation.cfm.

4. "Drinking Water Treatment," Environmental Protection Agency, http://water.epa.gov/lawsregs/guidance/sdwa/upload/2009_08_28_sdwa_fs_30ann_treatment_web.pdf.

5. Donohue, M.J. et al. "Widespread Molecular Detection of Legionella pneumophila Serogroup 1 in Cold Water Taps across the United States," Environmental Science & Technology, 48(6) (2014), DOI: 10.1021/es4055115, www.pubs.acs.org.

6. "ASHRAE releases Legionellosis standard for fourth public review," American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), press release, Sept. 29. 2014, www.ashrae.org/news/2014/ashrae-releases-legionellosis-standard-for-fourth-public-review-draft.