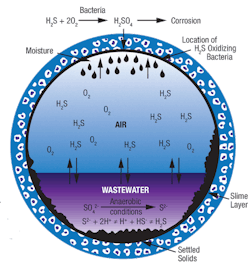

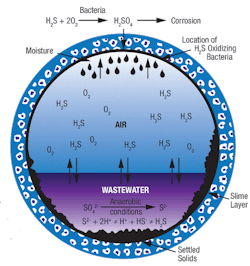

Corrosion of concrete sanitary sewers due to biogenic acid formation is a major problem for sanitation districts in many parts of the world. Sewage system materials can experience aggressive acid corrosion and significant nuisance odor. Corrosion can reduce collection system asset life and increase funding requirements associated with rehabilitation and replacement.

A large Australian municipality has applied a sewer corrosion protection and odor mitigation technology as a cost-effective method for protecting critical sewer assets without the need to divert sewage flows or typical man-entry requirements and with minimal disruption to its customers. Most recently, it conducted a project from 2011 to 2013 that utilized Sulfalock HiGel™ from IXOM Watercare to protect more than 17,000 meters (over 10.5 miles) of sewer assets from concrete corrosion.

SulfaLock™ is a low-viscosity solution of magnesium hydroxide, a gentle alkali reagent widely used for acid neutralization. When added directly to wastewater, it effectively controls odor and corrosion problems in sewage networks. HiGel is a specially formulated thixotropic product designed to be sprayed onto concrete assets subject to acid corrosion. Applied to sewer lines, maintenance holes, pump stations, wet wells, and chambers, the suspension eliminates acid corrosion and increases the asset life by forming an alkaline coating, which protects the integrity of concrete sewer walls for 2 to 3 years.

The sewer asset protection process is performed in three distinct phases: surface cleaning, coating application and monitoring. The surface preparation involves the use of standard pipe pressure cleaning to remove the slime layer and loosely bonded corrosion. The coating application phase is completed without typical man-entry requirements using a modified spray boat for crown application and a hand-held spray lance for manholes, lift stations, etc. The last phase, long-term monitoring, involves measuring the pH of surface samples from the treated areas. As substantiated by Los Angeles County Sanitation District, there is a direct correlation between surface pH and corrosion rate.

The monitoring is ongoing; however, results of this recent project are consistent with previous projects. For example, the initial surface pH generally ranged from 2 to 3. After HiGel application, the surface pH values were above 9. After nine months, the pH values remained above 9 and after 24 months, they were still well above 8. Thirty-six months after application, the lowest pH measured 6.4, demonstrating continued corrosion protection.

Furthermore, the coating exhibits a robust physical character (demonstrated by the need to chisel or scrape the surface in order to obtain sample material) and strength of adhesion (demonstrated following surcharging conditions where the pipe flowed full in turbulent conditions).

The coating application provides a cost-effective method for protecting critical collection system assets while allowing the municipality to better prioritize capital expenditures by significantly postponing rehabilitation and replacement.

IXOM Watercare is an exhibitor at WEFTEC.15 and can be found at Booth 3871. For more information, visit www.ixom.com.

References

1. S. Barclay, et al. "Trials of the Corrosion Inhibitor, Sulfalock HiGel," Journal of the Australian Water Association, February 2007.