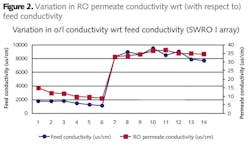

Water is hard to come by in the desert, and expensive to produce for industrial use. A trial with a major petrochemical company shows that although oil and gas wastewater is hard to treat, with the right technology, strict reuse standards can be met. Ajanta Sarkar and Vikrant Sarin describe the EQUATE pilot and implication on the broader region.

The Middle East and North Africa (MENA) region is the most water scarce region of the world, and in recent years, the amount of water available per person has declined dramatically. The acute scarcity of water, coupled with escalating cost of fresh water and its treatment in the Middle East, has prompted the region's industry, which primarily is oil and gas based, to think of water conservation and recycle.

EQUATE Petrochemical Company in Kuwait, a manufacturer of ethylene, polyethylene and ethylene glycol, decided to explore the possibility of recycling treated wastewater for internal use in process requirements. To this end, the Kuwaiti firm signed a plant-based water recycle deal with Aquatech to develop and pilot a solution as part of a full-scale wastewater recycle project.

The goal of the project – part of the EQUATE Green Initiative – is to reduce water consumption and decrease the carbon emission associated with purifying water by recycling and reusing treated wastewater for internal use in process requirements to the maximum possible extent.

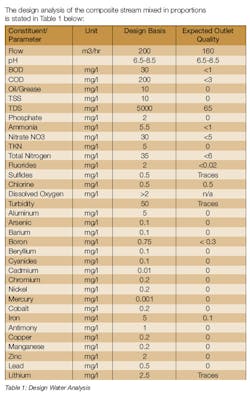

The project involves treating multiple waste streams contaminants such as oil and grease, volatile organic compounds and high dissolved solids levels with potentially high variation in constituents from the facility to maximum recovery. Since the quality requirements of process water are very stringent, EQUATE wanted to thoroughly examine the concept of reusing the treated wastewater before implementing the full-scale project, and therefore, the project involved piloting.

The above analysis indicates that the water had a high fouling potential and is difficult to treat. The scheme provided uses a combination of membrane technologies resulting in 80% of the treated effluent being purified to < 50 µS (microsiemens)/cm conductivity. This meets the requisite norms set by the customer for reuse in the process.

The process scheme

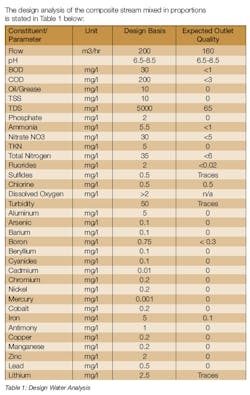

An innovative scheme was designed to achieve maximum recovery of high quality water from a wastewater stream of 880 GPM (200 m3/hr). The actual plant would recover 160 m3/hr for reuse. This system combines membrane-based technologies to remove suspended, biological and inorganic impurities from the treated wastewater to make it fit for use in the process. It is designed to accommodate a wide range of operating parameters like flow, TDS and temperature without affecting the final treated water quality. This system also has an associated lamella-based unit to ensure further recovery of reusable water from some of the waste streams being generated from the plant. The scheme was expected to deliver: more than 80% recovery across Pass I; more than 90% recovery across Pass II and overall more than 80 % recovery. However, this design had to prove it could deliver the estimated recovery and quality treating wastewater onsite. A pilot study was then conducted.

Pilot study and outcome

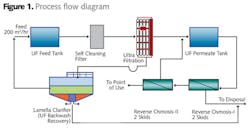

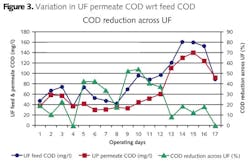

A scaled down version of the main plant was built for the pilot study. Testing then took place at the site of the effluent to establish performance. Data in Figure 2 and 3 demonstrate why the membranes selected were appropriate for the required application.

The system met the main criteria set by EQUATE by achieving the required stringent water quality parameters, delivering more than 80% recovery across Pass I, more than 90% recovery across Pass II, and exceeding the desired overall recovery of 80%.The UF membranes performed well in terms of turbidity reduction and achieving consistent Silt Density Index (SDI). It also showed good reduction in the percent of COD. The membrane system operated satisfactorily at the desired overall recovery of 81% and also in terms of conductivity and COD reduction.

The plant performed well with overall recovery of ~ 80%, which is equal to main plant overall recovery. The objectives of pilot plant in terms of quantity (recovery) and quality (critical parameters such as conductivity and COD), were achieved. Therefore, the pilot was deemed successful and the designed membrane set up was established. Broadly speaking, the project demonstrates that by taking full advantage of wastewater recycling, water conservation can be increased, as well as much needed resources in the MENA region.

Author's note: Ajanta Sarkar is the general manager, applications – Eastern, and Vikrant Sarin is manager, sales & business development, Middle East for Aquatech.

Process ElementsFeed Tank: The treated effluent from the effluent treatment plant is collected in a feed tank before being fed to the downstream recycle plant. Ultrafiltration: Feed water from the feed tank shall be filtered for removal of suspended matter to < 3.0 SDI. This is also used to reduce organics and COD. Ultrafiltration membranes were supplied by QUA. UF Backwash Recovery: The backwash waste produced in the UF system is treated in an inline lamella system in order to maximize recovery of the system by avoiding any waste disposal from the UF system. Clear water from the lamella is taken back to the feed tank for further recovery. RO Block: The above water is then preconditioned and passed through cartridge filters, which act as a safeguard against media breakthrough from the preceding units, followed by the reverse osmosis equipment using RO membranes supplied by Dow. This system operates at very high efficiency in terms of recovery – i.e., about 80 - 85%. It removes the dissolved impurities from the stream and produces a permeate stream of lower TDS and a reject stream of higher TDS. Permeate is taken to the second pass RO for improvement in quality in terms of desired organics level and conductivity requirements. This permeate is used for the main process requirement. |