Water access challenges and new mining discharge regulations are creating opportunities for the application of new water technologies. Yet the size and complexity of operations and cost of treating mining wastewater has slowed innovation. Which technologies/companies are emerging as successful?

By James Fotouhi

As with many industrial sectors, the treatment of wastewater in mining applications is a secondary consideration tied to environmental policy and regulation, rather than a core operating practice.

As a result, many operators focus on well understood processes that require significant civil work, such as lime softening, tailings storage and chemical precipitation to be used as the primary system applied for heavy metals removal. However, in some instances novel and innovative technologies have been adopted with beneficial results.

There are several drivers leading to adoption of more advanced treatment technology, including:

- In Chile, increased water scarcity is leading to the adoption of desalination for supply

- Reductions in allowable discharge limit for selenium from Canadian mines

- Need for mining companies to protect local environments from contamination and maintain a social license to operate

- Declining investments in mining related projects and increased operational cost are driving a need to make existing projects more cost effective.

Desalination drive in Chile

According to a recent study by Moody's Investor service, approximately two thirds of mining operations for the six largest hard rock mining companies are located in water stressed regions of the world. Water risk and scarcity in mining are increasingly areas of concerns for the industry and have driven investigations into the application of advanced treatment solutions.

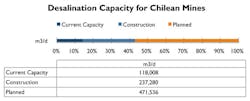

For example, decreasing water resource availability has pressured the Chilean government to prioritise domestic access over the mining industry. This is particularly apparent in the Atacama Desert, where mining projects need to ship desalinated seawater several hundred kilometers from the coast to supply operations with water (figure 2 shows current planned and installed desalination capacity for nine facilities).

Given the large distance and elevation required to supply mining operations from the desert, water costs are expected to be two to three times that of a conventional desalination plants.

Despite these considerable costs, desalination is expected to grow as a percentage of mining water supply, driven by legislation such as a proposal aimed at making desalination more mainstream for mining operations. This would require projects with water demand greater than 12,500 m3/day being solely supplied by desalination.

Canada – selenium removal solutions

Selenium - a metalloid present in trace amounts in mine waste - has gained increased regulatory attention due to its toxic effect on aquatic environments.

The mining industry in Canada has been watching the development of new Canadian selenium regulations, due to its prevalence in many ore types. Recent estimates indicate that significant quantities of selenium in 10-25% of Canadian mine sites may require mining operations to manage seleniumin wastewater.

Selenium occurs most commonly in two oxidation forms: selenium (IV) – selenite, and selenium (VI) – selenate. Selenite is relatively easy to reduce and precipitate chemically or biologically as elemental selenium, while selenate has a high oxidation potential, similar to sulfate, and can be present in large quantities in mining effluent. Figure 3 illustrates the different forms of selenium. Lime softening, the most common treatment technology for mining wastewater treatment, cannot remove selenate from solution. Thus, an alternate solution for selenium removal is required. Iron co-precipitation is the currently endorsed method by the US EPA for selenium but requires large volumes of chemical inputs and produces an unstable sludge by-product.

Investigations into biological reactors and constructed wetlands have demonstrated the potential for selenium removal. The characteristics of a mining effluent stream are not ideal for biological systems because mining effluent is highly variable in flow and occurs at low temperature, which limits biological growth. A combination of biological and chemical precipitation is usually needed to reach a selenium discharge level of 5 ppb.

However, in mining effluent the controlling contaminant for reactor sizing is often due to other anions (nitrates and sulfates) present in quantities 100-1000 times greater than selenium.

There have been developments of selective technology, such as ion exchange systems. Yet, again the presence of other anions such as sulfate and large effluent volumes, require significant quantities of resin and reagents.

Biological treatment technology

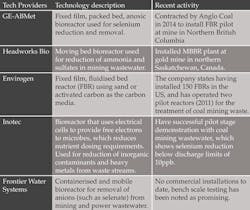

There are several biological treatment technologies being tested to economically remove the anions selenium, sulfate and nitrate from mining waste streams. These include metal sulphide precipitation, fluidised bed reactors, moving bed bioreactors, electro-chemical bioreactors and constructed anaerobic wetlands. Active tech providers in this application are listed in table 1.

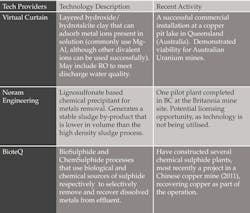

Chemical precipitation innovations

While lime softening and iron co-precipitation remain the primary processes in mining for heavy metals removal, there have been successful applications of alterative chemical precipitants.

These include metal sulphides, hydro talcites and lignosulfonates, which show high levels of metals removal and reductions in sludge volumes relative to conventional methods.

Sludge disposal from lime softening can be a significant cost for mining operations, particularly given the hazardous nature of the material. As a result, innovations that can reduce sludge volumes would be highly valued by the industry.

Water reuse + conclusion

Emerging treatment technologies in mining applications include biological systems for anion removal, alterative chemicals for metal precipitation, investigations into physical separation technologies for concentrating and recovery process streams and ion exchange systems used for recovery and metals removal.

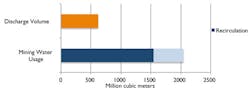

Process water recirculation is a common practice in the mining industry as it can reduce tailing storage, water intake and effluent discharge volumes.

Canadian mines frequently reuse three to four times before trace contaminant build up negatively impacts the ore extraction process (Figure 4).

Treatment technology is not commonly employed to enable process reuse, as the non-precious metal concentration can be effectively managed with additions of non-contaminated intake water.

There is a risk of contaminant retention when large quantities of process water is recirculated water, which can lead to scaling, corrosion and geochemical interference.

While mining wastewater reuse is uncommon, there are notable examples in South Africa of companies reusing effluent for potable and non-potable applications. The application of innovative wastewater treatment technologies is leading to significant benefit in the mining sector. In many contexts regulatory reform calls for the adoption of new technologies to ensure mines maintain their ability to operate.

A variety of technologies have already seen promising results from biological systems, to reuse and separation technology. While investment in greenfield mining is waning, water access challenges and increased regulation are necessitating the adoption of advanced treatment solutions.

James Fotouhi is a Research Analyst at Bluetech Research. The article is based on the report: Wastewater Treatment in Mining Metals. For more information on the report, visit: www.bluetechresearch.com.

More Water & WasteWater International Archives Issue Articles