By Dr. Christian Kabbe

To sustain good agricultural harvests, about one million tons (907,185 tonnes) of mineral phosphorus have to be imported into Europe annually. However, the potential to recover and recycle this essential resource remains untapped or, in the case of sewage sludge, is currently inefficiently used.

In the recent years various technical alternatives to the traditional but disputed application of sludge in agriculture have been developed to recover the nutrients. User friendly solutions have already made their way to full-scale or at least pilot-scale application.

Yet, it is not enough to just recover nutrients. To achieve real recycling, the gap between recovery and return of phosphorus into the nutrient cycle needs to be closed. The supply side needs to match with the requirements of the demand side and the regulative framework.

Phosphorus recovery

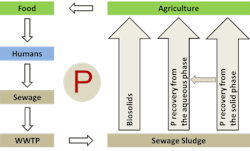

For the implementation to market, new technologies need to be proven capable and feasible. Today, three main routes for phosphorus recovery are discussed and partly demonstrated. As shown in figure 1 and given the fact that most of the phosphorus entering a wastewater treatment plant (WWTP) ends up in the sludge, three principle and complementary routes for closing the phosphorus cycle by recovery from the wastewater stream appear to be reasonable.

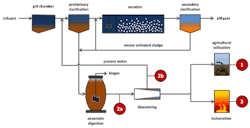

Meanwhile, figure 2 illustrates the hot spots for phosphorus recovery from wastewater. Direct application of stabilised sewage sludge or so-called biosolids on arable land is the traditional path to valorise the contained nutrients in agriculture, as long as they can be taken up by the roots of the crops.

The UK and several European countries favor this solution and it will remain one of the pillars for phosphorus recycling on international scale. To make this path as safe as possible, harmful substances within the wastewater treatment scheme should be replaced by harmless alternatives. Current monitoring routines hardly reflect the chemical constitution of a heterogeneous matrix like sewage sludge.

Depending on wastewater treatment infrastructure, phosphorus can be technically recovered from the aqueous phase of the sludge prior or subsequent to the sludge dewatering process. If sludge is incinerated in mono-incineration plants, the resulting ash contains the highest available concentrate of phosphorus within the wastewater stream. But, due to the very limited plant-availability of the nutrient within the ash, further treatment is obligatory.

Struvite recovery

Struvite (magnesium ammonium phosphate) tends to be a favored approach and is the final step of many phosphorus recovery technologies. It can provide a slow-release fertiliser with excellent plant-availability of the nutrients phosphorus, nitrogen and magnesium. It is even considered a suitable mineral fertiliser for organic farming.

Prior to dewatering, by crystallising struvite directly after the digestion within the sludge, the efficiency of the sludge dewatering can be increased dramatically. In large WWTPs like Berlin Wassmannsdorf (operated by utility Berliner Wasserbetriebe) this kind of optimisation after installation of an AirPrex® unit led to substantial reduction of operational costs for the WWTP summing up to several hundred thousand Euros per year, even without selling the struvite.

These benefits are mainly achieved by reduced disposal costs due to improved dewatering of sludge, lower polymer demand and lower maintenance costs (scaling in pipes and abrasion in centrifuges) and a reduced return load in the sludge liquor. Every process optimisation has the potential to increase the overall energy efficiency.

One proven option to enhance the yield of struvite is a combination with thermal (for example, using technology from Norwegian firm, Cambi AS) or chemical (i.e. PONDUS, Germany) hydrolysis for disintegration of excess activated sludge.

Besides improved biogas production in the subsequent digester, also insoluble or hardly soluble polyphosphates are transformed into soluble ortho-phosphate available for struvite crystallisation in the sludge water. Both combinations will be implemented in full-scale in the coming months and years in the cities of Brunswick, Uelzen, Salzgitter and others in Germany.

Heavy metals and impurities

Recovered struvite within the sludge might include more impurities than the material crystallised from the process water after dewatering.

But, in the end, both qualities are already certified safe fertilisers (i.e. Berliner Pflanze or Crystal Green from Canadian firm, Ostara). Every plant operator needs to choose the option that fits the most to his expectations, needs and infrastructure.

Operational benefits are of course a strong argument, especially when the feasibility of the technology is independent from the sales price for the obtained recycling product. Unfortunately, most of these technologies are limited to WWTPs with enhanced biological phosphorus removal (EBPR) followed by digestion.

If the phosphorus is removed from the wastewater by precipitation in form of hardly soluble iron or aluminum salts, which is the case for most of the existing wastewater treatment plants, direct struvite crystallisation is not feasible. The phosphorus needs to be remobilised first, normally done by hard chemical treatment like acid leaching at low pH value.

The challenge within this approach is the separation of the simultaneously remobilised heavy metals from the phosphorus and the post-treatment or disposal of the contaminated acid solutions. The higher the targeted phosphorus yield, the higher the chemicals consumption and collateral impact on the WWTP and the environment. So, high phosphorus recovery rates (>70%) can only be achieved at high cost.

A very promising and green alternative is being developed by the German company Budenheim. Here, only applying carbon dioxide as solving agent that is internally recycled and then plant-available and marketable dicalcium phosphate is precipitated.

Recovery rates above 50% have been demonstrated in medium scale and are now to be replicated and increased in pilot scale in the cities of Mainz and Itzehoe. The co-incineration of the phosphorus degraded sludge solids in cement kilns opens the door for zero waste scenarios.

Incineration options

When the sludge is about to be incinerated in mono-incinerators, several options for phosphorus recovery can be applied. Currently, only a part of the sludge is incinerated without dilution. With a lack of ash treatment facilities and interim storage capacities, most of the phosphorus in these ashes is lost.

If legal requirements will enter into force as currently being discussed in Germany, the future of thermal treatment of sewage sludge must include phosphorus recovery. Co-incineration means dilution of the phosphorus content and will therefore be restricted, unless the phosphorus has been removed before.

If sludge is incinerated in a mono-incineration plant (Figure 2, number 3) a high phosphorus concentrate can be produced from waste streams. The phosphorus content in municipal sewage sludge ashes (SSA) ranges between 2% and 12% in Germany. But, due to very limited plant availability of the nutrient within most of the ashes, further treatment is needed before it can be fully used as a resource.

The reality is that with a lack of ash treatment facilities and interim storage capacities, most of the phosphorus in the ash is lost today. Looking at existing infrastructure, it looks promising if we partly substitute phosphate rock in commercial fertiliser production.

European fertiliser companies have already started to test the substitution potential of sewage sludge ash and other secondary sources, even on a large scale. However, the application is limited due to legal barriers for the integration of waste material and specific requirements from the operator's perspective. Desirable high phosphorus content in the ashes, iron and chlorine also turn out to be a limiting factors among others here.

Commercial progress

Comparable to that scenario is the wet chemical extraction and ion-exchange purification of low-grade phosphate rock and other raw materials developed by Belgium company, EcoPhos. This allows the production of high-grade phosphates.

Two facilities are currently in preparation: one demonstration plant in Varna, Bulgaria followed by a full-scale facility in Dunkerque, France. EcoPhos had just signed a contract in February 2015 with SNB and HVC, both Dutch mono-incinerators, to recycle phosphorus from 60,000 tons of sewage sludge ash. A similar route is intended by the German company Remondis Aqua with its TetraPhos technology, yielding high-grade phosphoric acid.

The first pilot unit is currently assembled in Hamburg and said to be quickly followed by a full-scale plant (20,000 to 25,000 tons ash/a) on the same site.

Looking at the Mephrec (metallurgical phosphorus recycling) process developed by German company Ingitec, thermal valorization and phosphorus recovery in one single step are not mutually exclusive. A pilot project is currently in preparation in the city of Nuremberg, Germany. If a municipality or region decides for a new mono-incineration, the integrated solution of mono-incinerator and ASH DEC recovery module provided by Outotec might be an elegant option as well.

Outlook

A focus should be put on bringing existing and feasible technologies to the market and not to increase the spectrum of technologies. The current legal framework and the low prices for raw materials have to be considered as market barriers.

At current price levels for phosphate rock and other raw materials, only legal requirements are likely to boost a wide-spread implementation of phosphorus recovery and recycling from the wastewater stream. Ideas for creating a level playing field for fertilisers have to materialise. This is regardless of whether they are made from fossil or secondary sources.

Otherwise, recovery and recycling technology will not be implemented in Europe if it is not providing benefits to its operators under current conditions. There is a lot of know-how waiting to be shared with huge potential to be creatively transformed into innovation. Think forward, act circular!

Dr. Christian Kabbe is from the Berlin Centre of Competence for Water, Germany. Email: [email protected].

More Water & WasteWater International Archives Issue Articles