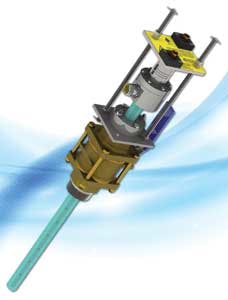

A new electromagnetic flow meter that will be on display at WEFTEC combines the accuracy benefits of full profile measurement with the advantages of an insertion type installation.

McCrometer's patented FPI Mag™ - Full Profile Insertion Mag Meter - spans the entire internal diameter for pipes from 4" to 138". Along the complete sensor length, magnetic coils are installed internally, with stainless steel electrode pairs installed externally. This enables flow data collection from the entire flow diameter and accuracy up to ± 0.5% from 1 ft/s to 32 ft/s and up to ± 1.0% from 0.3 ft/s to 1 ft/s.

The FPI Mag is precalibrated by McCrometer in one of its three NIST traceable calibration facilities. The meter can be configured for forward only or bi-directional measurement. The single piece, structural stainless steel sensor is coated in a NSF certified, 3M fusion bonded epoxy coating and has been rated IP68 for submersible applications.

All electromagnetic flow meters use Faraday's Law of Electromagnetic Induction. The principle states that a conductor passing through a magnetic field induces a voltage. The voltage magnitude is directly proportional to the velocity of the conductor. Electromagnetic flow meters create a magnetic field within the flow conduit and collect the voltage induced by the flowing, conductive water. A converter translates the magnitude of the voltage to an average flow rate. The electromagnetic approach is inherently reliable and can provide excellent accuracy.

Electromagnetic flow meters are offered in two types, flanged spool and insertion. Flanged spool type flow meters are bolted into, and become a segment of, the flow line. The alternative is the insertion type flow meter which requires only a tap in the pipe wall through which the sensor can be inserted. This simplified approach offers substantial logistical and cost advantages.

The typical flow profile in pipes is variable, having been disturbed by flow disruptors such as elbows and valves. Achieving optimum accuracy requires collecting data from the full profile of the flow to account for this variation. While spool meters are full flow profile measuring devices, they can be expensive to procure and complicated to install (pipe cutting, flange welding, heavy equipment, etc.). This is particularly true for spool meters used in medium, large and extra-large pipes.

In many applications, the FPI Mag can save customers 45%+, when taking into account both the installation and meter costs. Other insertion type meters on the market extend only partially into the flow stream, measuring just the portion to which the sensor is exposed. An average flow rate extrapolated from this limited sample is subject to error caused by flow profile variations.

For new water facility designs the FPI Mag can be installed in short pipe runs using a dry tap procedure; this provides greater meter location flexibility, smaller plant footprints, less installation time and lower cost.

For systems needing additional flow meters or an existing meter performance upgrade, the meters can often be installed without shutting down the line by using a hot tap / wet tap insertion approach. In the event a plant operator would ever want to inspect the meter, it can be easily removed, leaving the system flowing in its absence, without the need for a surrogate spool.

The municipal market is using the FPI Mag in raw water, filter balancing and backwash, UV dosing, treated effluent, booster stations, distribution and totalized billing applications. The industrial market is using it in chilled water, cooling water, fire water, feed water, inlet to surge basins, and clean effluent applications.