In 2008, a large water utility in South Carolina purchased the Hach Water Information Management Solution™ (Hach WIMS™), a commercial-off-the-shelf data management tool widely used throughout the water and wastewater industry. The utility bought the system to help capture data from external sources (SCADA, Laboratory Information Management Systems, etc.) and create standardized regulatory reports.

However, the utility decided to take the system beyond its initial intent of regulatory reporting and use it to strengthen operational efficiency.

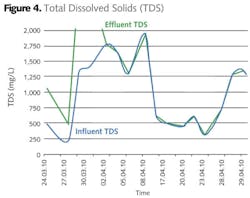

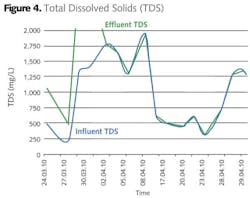

The report signals when the measurement standard (grab) is posssibly in error by comparing trends of similar measurements at different locations during the same time period.

All four grabs show the same trend and timing, indicating a possible problem with the measurement standard.

The utility has approximately 60 different instruments specific to water quality. At the time of the WIMS purchase and implementation, instrument calibrations were completed once a week. Instruments were calibrated based on one-time grab samples that were performed the morning of the scheduled calibration checks. Any instrument deviation out of specification from the grab (standard) raised a red flag and forced the crews to inspect and calibrate the instrument.

However, there were several issues with this calibration process: the instrument reading could potentially be incorrect for seven days until the next calibration process; the one-time grabs could be incorrect resulting in an unnecessary and potentially incorrect calibration; and there was no clear way to tell if the calibration solved the issue until the next week's series of one-time grab data.

Having used the data management system for over a year and understanding more fully its analytical capabilities in conjunction with its reporting engine, utility management decided to employ standard features of the software in a creative way to help with their calibration process.

Using data generated directly from the system, the utility created an Instrument Calibration Analysis (ICA) report, a report which compares daily grab and online SCADA data for specific instruments, records the differences over the past seven days, and notes any alarms generated over the past five days.

The ICA report has provided substantial benefits to the utility. Most recognizable is its ability to offer staff at all levels timely feedback on the status of their instrumentation. The report allows the utility to make more efficient use of staff time - focusing on areas of concern as opposed to trying to locate problems.

Promulgated throughout the organization, the ICA allows staff to evaluate data and investigate to see if issues are real or imagined. Review of the calibration records and trends, along with application of their tacit knowledge, enables staff members to identify if the trend is meaningful. Management also benefits from the analysis, obtaining notification of potential overall utility issues and determining necessary trends for budget purposes.

In addition to the enhanced visibility, the analysis provides the utility with substantial benefits in various areas, including the following:

- Reduces errors associated with a one-point calibration. The analysis ignores single special-case data points and trends data to ensure accuracy.

- Manages variations of measurement methods. The 'run analysis' determines any inaccuracies of the instrument; no matter the extent of the variations.

- Reduces the amount of time an instrument is reading incorrectly. The reports provide daily notification if an instrument needs attention.

- Quantifies inaccuracy of instrument to ensure consideration during data analysis. The report highlights any issues with an instrument as it displays the general trend of the instrument over several days.

- Reduces the manpower involved in weekly calibration checks. The analysis negates unnecessary calibration checks on instruments, resulting in a substantial cost savings in the reduction of labor.

- Creates trended results of adjustments made to instruments. The report allows individuals to quickly see the benefit of any necessary calibrations and records the number of adjustments that have been made on each instrument, trending the results to alert any future maintenance or replacement issues.

- Signals when the measurement standard is possibly in error. The analysis helps compare trends of similar measurements during the same time period, which shows if the method for reading the standard is in error.

No matter the parameter that is being tracked, the analysis allows the utility to take action in advance of the problem, as well as be more efficient. For example, the dosage and usage of chlorine is actively monitored. Review of the data guarantees that the appropriate residual is fed, ensuring an accurate outcome and resulting in lower chemical costs.

Based on the success they have recognized for in-process activities, the utility is now looking to expand to end-of-process activities. Recently, the utility's process staff added typical data from their chemical feeders to provide a comparison to what the SCADA system demands and the feeder's actual output. The test confirmed that the feeder was in compliance. The calibration will be monitored to determine how often maintenance needs to be completed.

Scott Dorner, Hach WIMS Project Manager, is impressed with the utility's enhanced use of the information management system.

"Due to the amount of information that is typically compiled, an organization cannot possibly look at every single piece of data. Termed as 'Management by Exception,' Hach WIMS allows an organization to assemble only the necessary data and spend their time and energy on the areas of concern. This South Carolina utility understands the true advantages of Hach WIMS – specialized and analysis reporting customizable by the client."

In addition to the obvious benefits, the Instrument Calibration Analysis has provided a 'softer' benefit: an enhanced relationship between the instrumentation personnel and the process control staff. Both groups actively support the use of the ICA and its ability to pinpoint any concerns with the instruments or the calibrations.

There are future enhancement opportunities for the ICA. Currently, the report is used on 25 of the utility's 60 instruments, with potential to develop reports for all instruments. There is also a strategy to automate the report – forwarding an e-mail or text to alert the Operator of any issues or inspections required upon the start of the workday. Weekly calibrations will become a thing of the past. WW

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles