Ultraviolet (UV) light disinfection has emerged as an important tool for wastewater treatment plant operators. This technology-based alternative to chemical disinfection for processed effluent improves the safety of plant environments, achieves equivalent control of microorganisms at acceptable cost and avoids the toxic byproducts addressed in increasingly stringent environmental regulations.

As the final link in a treatment plant's process chain, UV at prescribed doses controls harmful pathogens by blocking their DNA necessary for cell division. UV became an accepted disinfection alternative starting in the mid-20th century. The technology can reliably destroy 99.99 percent of all bacteria and viruses with only seconds of exposure to the eerie green light emitted by UV lamps. Further, the eco-friendly benefits can directly complement the current trends in water reuse for industrial installations, irrigation and recharging stressed aquifers.

The city of Summerville, Ga., built a 2-MGD wastewater treatment plant in 1967 to handle the flow of a developing municipal collection system that now serves 1,860 connections. Improvements followed in the late 1980s with continued use of chlorination and SO2. During an upgrade in 2008, the city's consulting engineers recommended abandoning chemical disinfection in favor of replacing it with a WEDECO UV system. The system consists of 60 lamps configured as two banks of three modules each set in a single open channel. As with other elements of the upgrades that year, the plant received air diffusers, a blower motor, an additional pump, and improved lighting.

"We operated the system at a 35 mJ/cm2 dose for nearly five years," recalled Scott Millican, plant operator. "The plant was easily meeting our permit requirements at that dose by alternating the operation of only one bank of lights at a time under a power draw at 50 percent. After more than three years, we raised the set point to 100 milli-Joules to maintain the original fecal kill," he explained. "That dose still achieved well below our permit's allowable fecal count."

However, nothing man-made lasts forever. Eventually, two of the original lamps failed and were replaced with spares procured with the original UV contract, which left only one replacement lamp in the parts inventory, Millican recounted. The other 58 lamps continued to operate at 100 mJ/cm2 dose and delivered the necessary UV-C but with 32,000 hours of operation, triple the 12,000 hours of guaranteed life expectancy. Consequently, Millican urged his former superintendent to proactively replace all the lamps in the system to ensure against a rash of simultaneous burnouts.

"I wasn't alarmed even when we finally raised the set point to 100 milli-Joules, but the original lamps were surely approaching the end of their life," Millican said. "However, our former superintendent mistakenly presumed that all UV lamps were essentially the same, so he sought competitive quotes on OEM replacements against a cheaper line of UV lamps. He went with the lowest price, which set the stage for trouble."

At some point in the quote process, a set of the cheaper lamps was shipped with the wrong ballasts. That error was corrected with the right lamps, he said, but not before 21 man-hours were essentially wasted during the changeouts. Even so, the correct aftermarket high-output lamps to fit the system were finally installed but failed to meet expectations within eight months.

"We ran them only one year, but even at 100 percent power, our fecal counts were close to exceeding our permit," Millican said. "We sought quotes for several lines of replacement lamps but were committed up front to the originals. Both the city manager and new superintendent agreed that the higher cost was logical because the lamps were matched to the system.

This led the newly-promoted superintendent to earn approval for emergency procurement of the UV system manufacturer's recently introduced ECORAY® lamps as replacements.

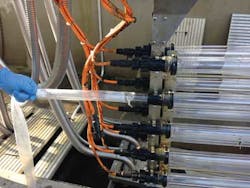

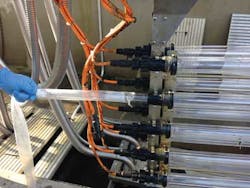

The high-performance, low-pressure lamps and companion electronic ballast cards were installed in mid-April. Offered both as OEM or replacement lamps, the new units at Summerville are more efficient, longer-lasting, more stable, and more sustainable than previous technology. Total operating costs have been typically reduced by 20 percent at many installations because the lamps normally operate more efficiently in dimmed mode but still achieve desired control. At the Summerville plant, the energy use already has been significantly reduced.

The new line of UV lamps also incorporates environmentally friendly engineering features. The lamps contain 80 percent less mercury and can achieve 500 kg CO2 in each unit. The manufacturer meets the highest environmental standards for Certification to DIN EN ISO 14001.

Following the initial weeks after installation, the system was reverted back to an automatic set of 36 mJ/cm2. The automated setting best serves the plant's limited workforce, which comprises six Class I operators who are also trained to run their own process control and reporting samples in the plant's lab.

The experience proved one point to the Summerville operators when it comes to purchasing replacement lamps and possibly other aftermarket parts: "The lowest price doesn't guarantee the best results," noted Tuggle.