By James Laughlin, WaterWorld Editor

A treatment system that generates power from biogas and uses exhaust heat from turbines to disinfect wastewater is currently conducting a pilot test at a Southern California treatment plant, demonstrating it's ability to process 500,000 gpd and potential to scale to treat 10-20 mgd.

The treatment system was developed by the Pasteurization Technology Group, a California-based company.

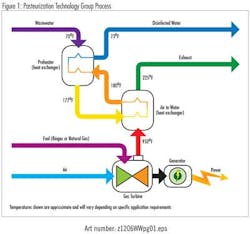

PTG's patented technology can use digester gas as fuel to drive a turbine that generates renewable electricity. The hot exhaust air from the turbine is then passed through a series of heat exchangers that increase the temperature of the incoming wastewater to a level that disinfects the wastewater stream, about 180 degrees.

The hot water is recycled back through the heat exchangers to pre-heat the incoming wastewater. That recovers the heat energy and cools the disinfected water to a level safe for discharge. The system is said to be over 90% efficient in capturing the heat energy.

Because it uses heat to disinfect the wastewater, the system eliminates the chemical and/or electrical costs typically associated with disinfection. An added benefit of using heat is that it can handle dirty wastewater streams; performance is not impacted by extremely high turbidity levels.

While use of digester gas to generate electricity and to fuel combined heat and power systems are becoming more common, this is the first system to use exhaust gas to disinfect wastewater, according to company co-founder and CEO Greg Ryan.

"We are the only company that I've run across in the world that in a single system combines on-site renewable energy as well as wastewater disinfection for reuse," Ryan said. "The fuel for our system is waste heat, and from an operational standpoint the cost of operating our wastewater disinfection systems are negligible."

The company is starting to gain interest from the water utility market after working on the technology for a number of years.

The company conducted initial pilot plant work at the Los Angeles County Sanitation District's Carson Plant in 2006-2007. After successful pilot testing at Santa Rosa's Laguna Plant in 2007-2008, the company passed the stringent standards of Title 22 in the state of California for the disinfection of water for reuse.

While the company's system is designed to using digester gas to fuel turbines or engines, some applications have tested use of natural gas for power generation and exhaust heat for disinfection.

In 2009, PTG conducted pilot plant testing at South Florida Water Management District, disinfecting canal water for an aquifer recharge project. The company also hopes to begin installation of a small natural gas-fired turbine generator/disinfection system for a Northern California water utility later this year.

PTG is primarily a systems integrator and selects components based on the size and needs of the utility. For smaller application, mini turbines from Capstone might be chosen. As systems get larger, generators from Solar Turbines, Siemens or GE might be used, depending on power demands.

After receiving $1 million in venture capital funding earlier this year, the company is accelerating its product development and commercial activities. PTG recently expanded its product line with the announcement of a mobile wastewater disinfection system that will help municipalities and engineering firms fast-track pilot studies of the technology.

The company's standard system, the PTG X-500, can process up to 500,000 gallons per day. The new mobile processing plant, the PTG XM-5 can disinfect up to 14,000 gallons of wastewater per day, sufficient for target customers in the wastewater treatment, food, beverage, agriculture, and oil and gas industries. This will allow customers to conduct cost-benefit analyses of the technology's capabilities prior to proceeding with larger implementations.

"We're experiencing strong commercial interest for our renewable-energy wastewater disinfection system because businesses are facing rising water, sewer and electrical costs associated with managing their wastewater output. We have a solution that handles their disinfection needs while also offsetting their power and water bills," Ryan said.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles