By David M. Faber

The Village of Dundee, MI, Wastewater Treatment Plant Expansion was completed and put online in August 2005. It used new materials and technologies including membranes for the principal treatment process and also for sludge thickening. At that time, membranes were on the forefront of new treatment processes in municipal facilities. Dundee's WWTP was only the second municipal membrane treatment plant in the state and, with average capacity of 1.5 mgd, it was the largest flat panel MBR plant in the nation.

From 2000 to 2005 Dundee's population had increased by 18% and growth in the commercial and industrial base in the village was even greater. The old plant was barely able to keep up with the increased flows and the sludge facilities did not have enough storage to comply with the state's detention requirements. Also, in 2003, the state of Michigan determined that a downstream portion of the receiving stream, the River Raisin, was not in compliance with its established warm water habitat designation. Therefore, Dundee's WWTP had to be upgraded to achieve effluent limits of Advanced Wastewater Treatment (AWT) technology. Summertime effluent limits for BOD and NH3 were set at 4 mg/l and 0.5 mg/l; respectively. The village was faced with the necessity of doubling the treatment capacity, producing a higher quality effluent, doubling the sludge storage detention time, fitting the treatment processes into an already confined site and providing for another future expansion on the same site.

Membrane Bio-Reactor

Dundee's former WWTP used a sequential batch reactor (SBR) treatment process. To meet the required effluent limits required by Advance Wastewater Treatment technology, a tertiary filtration process would have to be added to the expanded SBR process. However, the wastewater treatment plant site was too small to add such facilities. The initial plan of doubling the capacity of the plant with a larger SBR process would have maxed out the site and there would have been no future capacity at that location. The site is circumscribed by the river and other municipal buildings to the south, the railroad tracks to the east and private property to the north and west. Engineering evaluations were conducted to determine the type of wastewater treatment processes that would meet the regulatory limits but not require expansion of the treatment plant site. The Village selected a membrane bio-reactor (MBR) process for the new WWTP.

The new WWTP uses a system of flat plate membranes immersed within the biological treatment tanks. It was the first municipal use of this type of membrane in the state of Michigan. The biological treatment process operates with activated sludge concentrations several times greater than conventional activated sludge processes. The high density of the biomass allows for greatly reduced volumetric requirements to treat the wastewater. The nominal flux rate is about 10 gpd/ft2 at average flow. During the past five years of operation, the WWTP has produced an effluent that complied with the fecal coliform limits without the use of disinfection.

"Under most flow conditions, the WWTP operates well and the effluent is outstanding. We're actually improving the River Raisin with our effluent," said Dave Rigel, who was Dundee's WWTP Superintendent.

The WWTP's old structures and piping were modified while increasing the capacity from 0.75 mgd to an average capacity of 1.5 mgd with a peak flow capacity of 3 mgd. Provisions were also built into the new facilities to accommodate an average flow increase to 2 mgd with a peak capacity of 4 mgd. All of this was done without the need to expand the site.

Since the expanded WWTP in Dundee came on-line in August 2005, the MBR facility has provided both biological treatment and filtration to produce a high quality effluent meeting the strict effluent limits.

Membrane Thickener

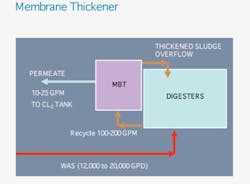

Waste activated sludge (WAS) is pumped to a two-cell aerobic digestion process that also employs membranes for thickening the sludge prior to disposal by land application. In the membrane thickener (MBT) process, sludge is pumped from the digester to a small tank with membrane filters and an overflow pipe simply returns the sludge back to the digester. While sludge is being circulated through the thickener, a small stream of clear permeate is constantly drawn from the membranes and discharged.

"The membrane thickener has been trouble-free for five years. It's great to simply decide when to thicken, turn the system on and let it run itself until we get the sludge concentration we want," Rigel said.

The membrane thickener requires less operator attention than traditional decanting procedures. Operators are able to thicken the sludge to as much as 5% solids. This reduces the number of tank trucks needed to haul sludge offsite by more than 50% and doubles the available volume in the digesters for storage. The sludge could be thickened to a greater concentration but it would pose problems with the existing sludge pumping equipment. In the past year, Dundee has saved more than $23,000 in hauling and disposal costs because of the performance of the membrane thickener.

The two digester tanks have been operated in alternating aerobic and anoxic conditions to go beyond nitrification and to further enhance nitrogen removal. The permeate from the MBT process is of such high quality that it can discharged directly to the chlorine contact tank. Normal decanting procedures could not do this because of the high levels of solids and nutrients typically found in the decant water. WW

About the Author: David M. Faber is Director of Engineering for the Village of Dundee, MI.More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles