A special sequencing batch reactor (SBR) system, demonstrating lower operating costs and lower sludge production than conventional SBRs, is providing greater than 99% removal of organics for the 2.4 mgd wastewater treatment plant (WWTP) in Reinbeck, IA. The Grade 3 SBR system, started up in May 2005, replaced a failing Grade 2 extended air activated sludge system. During treatment of over 200 million gallons of wastewater, only about 170,000 gallons of sludge has been produced.

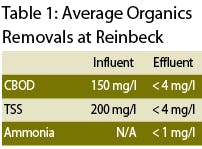

“We got good treatment within a month after startup, and have been getting consistently good effluent, even though our flow can fluctuate a great deal,” said Brad Evenson, WWTP operator for the City of Reinbeck. “Our influent CBOD averages 150 mg/l, and consistently drops to less than 4 mg/l in the effluent. TSS drops from average 200 mg/l to less than 4 mg/l, and ammonia in the effluent is consistently less than 1 mg/l. And usually people think a Grade 3 plant is harder to run, but this one is actually easier than the Grade 2 was.”

The design 0.730 mgd plant averages 0.250 mgd, with capability to treat 2.4 mgd in wet weather. Detectable limit for measuring CBOD is 4 mg/l; for TSS, 2 mg/l, and for ammonia, 1 mg/l. The ISAMTM-Integrated Surge Anoxic Mix system was manufactured by Fluidyne Corp. of Cedar Falls, IA.

The special system serves a population of about 1850 in Reinbeck, plus a recently added 60 in Morrison about six miles away. Influent CBOD peaks at 275 mg/l, and is down to 35 mg/l when groundwater is coming in. Influent ammonia is not measured. Evenson said the system’s fully-automated operation was especially important to the city.

“We only have two full-time guys to handle water, sewer, and streets, and don’t have the manpower to be at the sewage treatment operation for eight hours a day,” he said. “I average two hours a day at the plant during the week, and a half hour a day on weekends.

“Alarms on the PLC are hooked to an automatic dialer. That has told us things like an electrical problem that we traced to the contractor’s installation, as well as things that aren’t necessarily a problem, like more flow change alarms during wet weather.”

“So you can go down and check, and maybe speed up a pump, or see that a transducer is giving a false reading. It calls and tells you, so that you can be away from the plant and doing other things. With the old plant, with nothing automatic, you had to spend more time there, like to manually open valves to release sludge. It’s now a very low maintenance operation, with most stuff down there just paperwork, like sending the organics readings out to the lab.”

Evenson added that the PLC’s modem allows the system’s manufacturer to dial up to consult with him in real time.

“They can see everything that’s happening, on request,” he said. “For example, I’ve had some situations where I wanted to see if I could change run times when I was having electrical issues. They could see the problem wasn’t in the PLC, so I knew to look elsewhere. And with settleability, they could see where the cycles were at various times, and change DO settings to increase or decrease when you need it.”

“They’re not a company that just comes in and sells you a design. They know how it works. Not just the features, like other equipment experience we’ve had. They also know how the WWTP works, and can help you make changes.”

The city’s consulting engineer had been called on to replace a previous system that was overloaded hydraulically, and was only functioning marginally for organics removal.

“The city was advised by the Iowa Department of Natural Resources that their extended-air, activated sludge plant was in violation,” said Tim O’Connor, vice-president, environmental, for Veenstra & Kim of West, Des Moines, IA. “We did a facility plan, including identifying the particular deficiencies, and looked at alternative systems.”

“In addition to SBRs, we considered more conventional activated sludge, with separate clarifiers, but that would’ve required additional processes in the future for nitrogen and phosphorous removal. Oxidation towers could have taken care of ammonia, but not nitrogen and phosphorous. A lagoon system with controlled discharge was also considered, but its ability to handle ammonia requirements was questionable, except when high stream flows provided for sufficient dilution.”

O’Connor noted that SBR technology was favored not only because of cost analysis, but also concern with meeting future water quality regulations.

“We especially wanted a process that could be readily modified later to meet changes regarding nitrogen and phosphorous,” he said. “The anoxic phase of SBR, with mixing before oxidation, allows for that. The city had been told that its limitations were ammonia limitations, but nationally and also statewide, nitrogen and phosphorous are becoming more important to regulators.”

His firm had previous experience with SBR at five locations, and sought a manufacturer who could provide for a design dry weather flow of 0.3 mgd; wet weather flow of 0.73 mgd; maximum day of 1.75 mgd, and peak hour of 4.43 mgd. Design loadings were 464 lbs. BOD/day and 70 lbs. TKN/day. Design limits were set at CBOD, 25 mg/l average; TSS, 30 mg/l average; and average ammonia ranging from 2.7 mg/l to 14.8 mg/l.

“We narrowed from four or five SBR vendors to two − one with installations nearby, and the other with its headquarters nearby,” O’Connor said. “The comparative life cycle cost was within 5%, so the operator’s preference for the headquarters being nearby became a primary consideration, but there were also other items that favored the selected vendor.”

“The selected system had more flexibility for adjusting to higher flows, which also appealed to the operator, while the other was set the same for lower and higher flows, except for storm situations. And since the selected system was using less air as it went through a cycle, its operating costs were significantly lower, offsetting a higher capital cost in the life cycle analysis. But what was difficult to put into the life cycle equation was their anaerobic chamber, which provided for much lower sludge production than conventional SBRs.”

“At the selected vendor’s installations in Reinbeck and elsewhere,” he said, “we’re seeing 0.15-0.25 lbs. of sludge production per lb. of BOD removal, compared to 0.5-0.6 for conventional SBRs. That’s less than half as much to land-apply.”

O’Connor also pointed out that when the new plant was initially put into operation, influent was raw wastewater, without activated sludge seeding.

“We had tried seeding with other SBR startups before, to get quicker results, but there was deterioration in the effluent after an initial period of improvement,” he said. “Here, it took five days to fill the tanks and start discharging. The first readings were CBOD 26 mg/l, TSS 23 mg/l, and ammonia 15 mg/l, so we were already meeting limits at the first measure. Two weeks later, CBOD was 12 mg/l, TSS 16 mg/l, and ammonia less than 1 mg/l.”

He reported maximum monthly averages for the first 8 months of CBOD, 4.3 mg/l; TSS, 3 mg/l; and ammonia 1.93 mg/l. Of 35 samples taken for ammonia, 32 were below non-detectable (<1.0 mg/l).

“We have specified three other systems from this vendor, with the same results,” he concluded.

Fluidyne describes its Integrated Surge Anoxic Mix (ISAM)TM Sequencing Batch Reactor system as a single-train type, with a constant-level anaerobic selector chamber followed by a surge/anoxic/mix (SAMTM) tank, and then one or more SBR basins. It is designed to incorporate BOD, TSS, and nitrogen removal with sludge reduction, in an integrated process.

“We have observed that during the two-plus years of operation at Reinbeck, covering over 200 million gallons of influent wastewater,” said Erick Mandt, project engineer for Fluidyne, “they have only hauled away about 170,000 gallons of sludge, for an average daily conversion of about 0.1%. The typical conversion rate for biological processes is about 2%.”

In operation, all influent flow enters the anaerobic chamber, where solids settle in the manner of a primary clarifier. Elimination of primary solids at that stage is said to allow for much smaller SBR basins, at equivalent SRT, than with conventional SBRs.

The anaerobic selector is noted as creating soluble carbon as a food source for biological nutrient and phosphorous removal, through conversion of settleable BOD to soluble BOD, while forcing the release of phosphorous by subjecting the recirculated biomass to anaerobic conditions.

Influent then continues to the SAM surge basin, also known as the influent equalization basin. This part of the system is said to provide flow and nutrient equalization that allows for optimization of treatment at the full range of flows and loadings.

Mixed liquor is maintained in the SAM tank for immediate reaction with flow from the anaerobic chamber, in order to suppress odors, and also initiate and accelerate carbon and nitrogen reactions. In addition, mixed liquor is recycled from the top of the SBR tank, for removal of scum by a proprietary flow and scum control sub-system.

Nitrates are recycled to the SAM tank for denitrification, with reactions accelerated in the presence of unreacted carbon from the raw sewage entering that tank.

Aeration and energy requirements are said to be reduced, as nitrates are fully reduced to nitrogen gas there.

In addition to WWTP applications like the Reinbeck installation, Fluidyne’s ISAM has also been used as a stand-alone system to thicken and destroy organic sludge from other biological treatment plants, as a means for significantly reducing sludge disposal volume.