by Mary Fickert, David MacIntyre and Roberto Denis

A 26-month-long reclaimed water pilot study was recently completed for Orange County Utilities (OCU), Florida. The pilot study evaluated one of many innovative strategies aimed at using reclaimed water to meet increasing water demands in central Florida. The goal of the study was to assess the effectiveness of membrane technologies to treat reclaimed water for possible reintroduction into water supply sources.

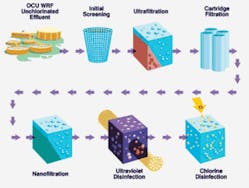

The pilot facility, one of the first membrane treatment pilots of its kind in the southeastern U.S., was designed and constructed in 2003 and went into operation in February 2004. The pilot initially included ultrafiltration (UF) and nanofiltration (NF) membrane processes, but was designed for later addition of a ultraviolet disinfection (UV) process. The pilot was designed to be an addition to an existing water reclamation facility, and it was initially placed at the OCU’s South Water Reclamation Facility (SWRF), prior to final disinfection.

Process Design

The pilot processes were selected to meet the Florida Department of Environmental Protection’s (FDEP’s) most stringent requirement for reclaimed water, called “full treatment.” In close coordination with the FDEP, OCU and the design engineers, PB, compiled and analyzed water samples for all full treatment requirements (Chapter 62-610, Florida Administrative Code) including:

- Primary and secondary drinking water standards, with primary being US Environmental Protection Agency (EPA) enforceable standards for health and secondary being EPA aesthetic standards.

- Mutagenicity (the capacity to induce mutations).

- Total organic carbon (3.0 mg/L max monthly average).

- Total organic halogen (0.2 mg/L max monthly average).

In addition to the parameters required to meet full treatment requirements, it was known that membrane processes could also remove an array of other drinking water constituents, including bacteria, viruses, protozoans, trihalomethane (THM) precursors, and microconstituents (e.g., hormones and pharmaceuticals). Therefore, the study was expanded to include them. However, quantitative analysis of many of these constituents fell outside the capabilities of most analytical labs, so OCU acquired assistance from the U.S. Geological Survey (USGS), Florida International University (FIU) and the University of South Florida (USF) to make use of the highly specialized analytical capabilities of their various research laboratories.

The pilot study began in 2004 as a UF-NF system but was constructed for flexible use and variable treatment schemes. The pilot plant was constructed in a road-ready trailer with an interior consisting of various pipe and valve configurations, all fastened to the trailer walls so that the plant could be easily relocated to other Orange County water reclamation facilities. The pipe and valve configurations allowed for process bypass and for the later addition of a UV system. Sampling ports were placed before and after each pilot process so that removal rates could be evaluated for each step of the process. Both the process permeate and concentrate streams were sampled and studied.

The UF membranes were chosen for their robustness and ability to remove total suspended solids. The NF membranes were chosen for their ability to reduce total organic carbon and pass total dissolved solids and chloride. These features made it possible to meet FDEP standards, but also leave a less-aggressive concentrate stream, or one with a lower total dissolved solids concentration, that can be easily treated in a typical wastewater treatment facility. The UV disinfection system was selected to provide an additional barrier to Cryptosporidium, Giardia, and other pathogens.

Focus Studies Successful

In August 2004, with six full months of data available and an understanding of the membrane behavior, the UV system was added. At that time, nearly all water quality parameters were being met. However, coliform levels were not, and the UV was expected to provide the necessary disinfection. Water quality results following the addition of the UV showed varying pathogen reduction effectiveness of the UV disinfection process, therefore OCU conducted two challenge tests in order to better understand the UV effectiveness.

The challenge tests introduced three types of surrogate microbial pathogens and bacteria of varying sizes upstream of the NF and upstream of the UV. The surrogates were measured before and after the NF and UV to determine the integrity of the NF membranes and of the UV unit after extended use. Both challenge studies resulted in a greater than 2 log removal of the E-coli and enterovirus surrogates by the NF membranes. The challenge studies demonstrated an average of 6 log removal of the surrogates by the UV unit.

In July 2005, the pilot facility was relocated to a second OCU water reclamation facility, the Eastern Water Reclamation Facility (EWRF), to show that results could be repeated on different water. EWRF utilized the 5-stage Bardenpho® Advanced Biological Nutrient Removal treatment process with fermentation, first anoxic, aeration, second anoxic, re-aeration, final clarification, filtration and high-level disinfection. This process differed greatly from SWRF which used advanced secondary wastewater treatment with flow equalization, chemical feed facilities, flocculation, tertiary filtration and high-level disinfection to meet public-access reclaimed water standards. The pilot process exhibited similar removal rates at the new location, demonstrating that the plant was versatile and could be put into service in various locations of Orange County.

Chlorination

The pilot effluent met all requirements of the full treatment rule at both reclamation facilities with the exception of nitrite and infrequent coliform detection. In addition, although the challenge tests proved that UV was reducing microorganisms in the water, daily sampling indicated that it was unable to destroy the colonies of regrowth that would occasionally slough off of the membranes and downstream piping. To correct this regrowth challenge, to oxidize the nitrite that occasionally exceeded drinking water standards, and to meet potential disinfection requirements, a chlorination step was added to the process in December 2005.

This additional disinfection step was studied for its effectiveness and continued for four months through the end of the pilot study. Results of daily samples were inconclusive due to wide variations of nitrite concentrations in the pilot influent and the pilot-scale dosing capabilities. However, additional focus studies were performed on the pilot effluent to demonstrate that constant chlorine monitoring and feed rate adjustment could control both biogrowth and nitrite concentration. Results were conclusive, and a full scale application is expected to meet nitrite and microbiological requirements.

Microconstituents such as hormones and pharmaceuticals were evaluated by the USGS and FIU. In 61% of the samples, microconstituents were below detection limits in the pilot effluent. Of the samples in which microconstituents like wastewater organics and pharmaceuticals were detected, the membrane processes reduced them at an average of 70%. Of the samples in which hormones were detected, the membrane processes reduced them at an average rate of 94%. These results are expected to be repeated at a full scale

Mutagenicity Test

In addition to the water quality parameters mentioned above, the full treatment rule requires that a pilot study show the “results of a biological testing procedure approved by the FDEP to determine the mutagenicity of the reclaimed water.” But a mutagenicity testing protocol did not exist. Therefore, the OCU Laboratory, in conjunction with the University of South Florida (USF), began devising a mutagenicity testing protocol in September 2005. Several available mutagenicity testing methods were studied by USF and the SOS chromotest was found to be the most reliable on the OCU reclaimed water.

OCU used the recommended test to study both upper-Floridan aquifer drinking water and pilot reclaimed water. Using the results of the studies and precision criterion guidelines outlined in Standard Methods (2005), OCU developed a protocol. The protocol was approved in 2006 by the FDEP and was the first of its kind in the State of Florida and set a precedent for future pilot projects.

The results of the mutagenicity testing showed that the pilot effluent was not potentially mutagenic. The upper-Floridan drinking water demonstrated similar results. The NF concentrate showed elevated mutagenic potential, indicating that the membranes were effective at reducing mutagenicity.

FDEP Coordination

Due to the innovative nature of this pilot study, it was important to keep the regulatory agencies involved and supportive of the pilot process. Therefore, quarterly meetings were held between OCU, PB, and the FDEP. Water quality data, operational issues, and system adjustments were all discussed during the quarterly meetings. These meetings provided an environment in which the FDEP could provide input regarding the process adjustments, and OCU could have questions answered regarding the future of the pilot study.

The Reclaimed Water Pilot Test was operated until April 28, 2006. With a total of 21 months of reliable water quality data, it was agreed by the FDEP at that time that the project had provided sufficient data to demonstrate the pilot process tested can meet the highest reclaimed water standards defined by the FDEP (full treatment).

About the Authors:

Mary Fickert is a water resources engineer and project engineer at PB. Her areas of expertise include surface water analyses, site development, membrane treatment process design and operation, and water resource planning. David MacIntyre is Manager of PB’s Water Technical Resource Center. He has over 20 years of technical experience in managing water quality issues associated with the reuse of reclaimed water. Roberto Denis is owner of Liquid Solutions Group, LLC, a water resources consulting firm in Orlando, FL. He has performed a variety of projects from small studies to large water supply infrastructure projects covering the broad spectrum of water resources engineering.