Just south of present day Lumpkin, GA, you can visit a reconstructed community from the 1850s and experience a taste of everyday life from that time period. In dramatic contrast, you will also find one of the water and wastewater industry’s most advanced filtration technologies in this same area. This technology was installed specifically to protect the Lumpkin area from the damaging effects of phosphorus-laden wastewater.

In June 2005, the Lumpkin Wastewater Treatment Facility installed continuous operation, downflow-design sand filter technology developed by Ashbrook Simon-Hartley. The new system helps the Lumpkin facility meet or exceed the requirements for effluent established by the State of Georgia (including possible new limits of 0.13 mg/L phosphorus, at some point in the future).

As an example of the system’s capabilities, records show with an average influent phosphorus (P) value of 0.84 mg/L, this downflow filtration technology achieves an average effluent P of 0.06 mg/L, using polyaluminum chloride as a coagulant. Turbidity has also been monitored through the filter. Starting with an average influent of 12.86 NTU, the turbidity is reduced to an average value of 1.77 NTU.

Today, well over a year after the installation of the Strata-SandTM filtration system, the technology is receiving high marks for both its effectiveness and its ease-of-operation.

Jim Murray, Lumpkin City Administrator, commented in a recent interview, “All my numbers are good; in fact, I’m at the low side of my parameters.”

The filter systems are available in steel or fiberglass package units or as filter modules installed in concrete basins. For the Lumpkin application, steel package units were chosen.

“The installation went well. We’ve gotten good support and the initial setup support and training was very good,” Murray said.

The Lumpkin facility began accepting flows from a nearby prison in 2006.

“We get a lot of phosphates coming into our system from the prison,” Murray said.

The efficient removal of phosphorus is critical because the entire area is dotted with pristine lakes and streams that drain into the Chattahoochee River, which runs through parts of three states - Georgia, Alabama, and Florida.

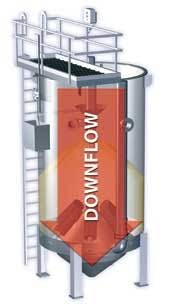

How it Works

Downflow filtration uses gravity as the prime mover. This means the influent does not have to be physically pumped through the filter bed, but rather flows freely. This simplifies the process and increases overall energy efficiency. In addition, the continuously cycling downflow filter media maintains coarse-to-fine stratification and bed integrity regardless of higher flow rates. The filter’s uplift system simultaneously removes solids and re-stratifies the media.

More specifically, with continuous downflow filter technology, influent is introduced and evenly distributed at the top of the filter bed. It then flows downward through layers of increasingly finer media. The media is contained via effluent screens arranged in the center of the filter, which direct the filtrate up through a riser pipe into an effluent weir box before discharge. Solids captured in the filter bed are drawn downward with the moving media bed into the suction area of an airlift pump. The turbulent upward flow in the airlift pipe provides a scrubbing action that effectively separates the media and solids before discharging into the filter washbox. The washbox has a media-water separation zone that allows gravity separation of the cleaned media and dirty water. The washbox has a long “skirt” at its bottom, which provides the final counter-current washing.