In May 2009, a new fiberglass wet well and valve vault were installed as a lift station for the Mountain Falls subdivision in Pahrump, NV. Ultimately, the Jane Avenue Lift Station will help transport wastewater for the development that will include 4,200 single-family homes, a day care center, a water park, a large recreational gymnasium, a casino and a church.

This recent Nevada installation is an example of a successful partnership between Xerxes Corp. and Romtec Utilities, both exhibiting at WEFTEC ‘09. Xerxes specializes in fiberglass tanks and structures, while Romtec is known for its package lift stations.

Previously, Oregon-based Romtec had used only concrete for the structural components of its pre-engineered package lift stations, said Mark Sheldon, the company’s vice president of engineering, marketing and sales. Now Xerxes fiberglass products are part of Romtec’s expanded product offering.

“Until Xerxes, fiberglass couldn’t compete structurally with concrete. In our view, Xerxes’ quality was a dramatic step forward for fiberglass in the water and wastewater market,” Sheldon said.

Xerxes has been well-known as a major tank supplier to the petroleum industry for decades. As of 2008, more than 150,000 of its fiberglass tanks had been installed at petroleum storage facilities.

When it came to deciding what product the developer wanted for this new residential and commercial subdivision, a fiberglass wet well was the obvious choice, according to Frank Strand, American West’s vice president of land development.

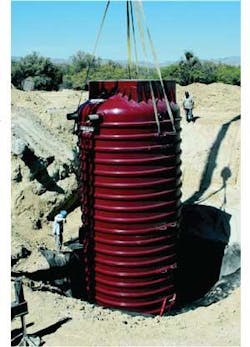

“This is the first lift station we’ve done. I’d seen another one, a concrete one, and I knew that wasn’t the way we wanted to go. I’d done my homework. We were much more confident in a ribbed fiberglass tank,” Strand said.

Xerxes tanks are designed with integral ribs for added structural strength. Because the integral ribs and tank are made of the same materials – high-quality resin and glass – and are manufactured as a monolithic structure, they are very robust, whether installed vertically or horizontally.

One of the advantages of a fiberglass wet well is its resistance to hydrogen sulfide induced corrosion.

“It is very, very corrosive,” Sheldon said. “Especially if you’re in a high-temperature climate, fiberglass is the obvious choice.”

When the 12-foot-diameter, single-wall wet well was delivered to Nevada, it was accompanied by a prefabricated 10-foot-diameter, fiberglass valve vault, complete with the valves, pipes and access covers necessary for the lift station to function properly.

As part of the partnership, Romtec Utilities’ technical personnel went to the Xerxes manufacturing facility in Anaheim, Calif., to ensure that all the components were correctly incorporated into the fiberglass structure.

“You can’t do that with concrete,” said Sheldon, referring to the factory assembly of all components and quality control possible in a tightly controlled manufacturing environment.

The completed structure was shipped to the site and installation went as smoothly.

“As fast as they could get it off the truck and into the hole, the wet well was set,” said Strand, who was on site for the lift station installation.

Greg Kiddell, owner and manager of the excavating company, Sati Construction, said the installation “went like clockwork.” He and his crew followed the manufacturer’s recommendations and the tank “went in easily and set perfectly. Just the way it was meant to,” Kiddell said. WW