With growing populations and landfill scarcity, many U.S. municipalities are searching for ways to manage biosolids in an economical and environmentally friendly manner. In some cases, reducing sludge volume is simply not enough today, as municipalities try to find value in everything they do.

In terms of sludge, value can be found in two different areas: sludge has value in its nutrient load and in the stored energy it contains. There is a growing consensus that the energy value is worth more than the nutrient value; therefore, processes that reduce volume and release energy are being sought.

Infilco Degremont Inc. (IDI) offers two sludge treatment processes that meet this trend. IDI's 2PAD(tm) Two-phase Anaerobic Digestion System and Thermylis(r) High Temperature Fluid Bed Incineration System reduce sludge volume and can minimize energy costs.

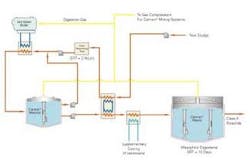

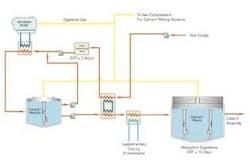

The 2PAD system is a two-phase anaerobic digestion process that incorporates a thermophilic-mesophilic layout. The first phase, operating at a temperature of 55

Heat recovery equipment - located between stages - helps keep energy requirements as low as possible. The two-phase nature of the system insures that each stage can be operated at peak efficiency, maximizing gas volume production while achieving Class 'A' sludge characteristics.

Digester gas from the system can be used as fuel by microturbines, co-generation equipment or boilers. The heat produced by these systems is returned to the digesters to maintain the operating temperature, while any electricity that is generated can be either used within the plant, or sold to the local utility. In many cases the electricity meets "green" generation criteria and as such helps utilities meet regulatory requirements for energy production.

Sludge produced by the 2PAD process has undergone extensive testing and has been certified by the EPA as Class 'A' unrestricted land application biosolids.

The thermal oxidation or incineration of sludge can serve as an alternative to land application. With over 20 installations around the U.S., IDI's Thermylis HTFB System is a high temperature fluid bed incinerator that offers two main advantages over other sludge processes: an absolute minimum amount of sludge production, and maximization of energy recovery.

Energy recovery is increased by a unique refractory dome incorporated within the reactor vessel. The dome allows more heat to be returned to the fluid bed.

The upper section of the reactor, above the fluid bed, is known as the freeboard. Rather than being constant, the freeboard diameter increases with height. This reduces the gas flow velocity as the flue gases move up to exit the reactor. The reduced gas velocity increases retention time, improving combustion efficiency and adhering to today's carbon monoxide and total hydrocarbon limits.

The Thermylis heat return process offers two distinct advantages. First, the incoming sludge does not need to be as dry as with a conventional system, reducing the complexities of sludge de-watering. Second, it is much easier to achieve autogeneous combustion; no additional fuel is needed and NOx emissions are reduced. Overall operating costs are also lowered.

The Ypsilanti (Michigan) Community Utilities Authority WWTP Expansion is one recent project using Infilco Degremont's high temperature fluid bed. After a review of incineration technology, The authority and its consultant, TetraTech MPS, decided to replace the town's aging multiple hearth incinerator. It was determined that incineration would be the most economic, efficient and environmentally friendly method for the city's biosolids disposal. Ypsilanti is expanding its capacity from 29 mgd to 46 mgd. The HTFB system will allow the authority to use available space while reducing odors and environmental emissions.