By Elsinore Mann

The US EPA estimates that 3% of national energy consumption, equivalent to approximately 56 billion kilowatt hours (kWh), is used for drinking water and wastewater services. The Energy Star program estimates that about $4 billion is spent annually for energy costs to run drinking water and wastewater utilities. If the sector could reduce energy use by just 10% through cost-effective investments in energy efficiency, collectively it would save about $400 million annually.

In the current climate of financial challenges and the anticipated increase in the cost of energy in the future, water utilities are responding with efforts to reduce energy consumption in all facets of system operation and maintenance. There are a multitude of energy savings incentives, both federal and state programs, and also from private utility companies that encourage large scale users to find ways to minimize their energy needs. (A comprehensive listing of incentive programs can be found at http://www.dsireusa.org.)

So, where do you start, and how can you get the most out of your system today? What changes can be made to reduce your operating costs at minimal expense? How can you reduce your utility's environmental impact?

Energy Saving Program

Many utilities have active programs to assess the efficiency of their operations and to find ways to reduce energy usage in their water systems. An effective energy reduction program should include a thorough review and assessment of all facilities to determine areas of inefficiency; identification of options to modify, rehabilitate or replace inefficient infrastructure; assessment of the costs of implementing the alternatives; and an estimated energy savings associated with each. Following this process will allow utility managers to be confident in their final decision on the preferred course of action.

To improve energy efficiency there are two main areas that can be addressed – the efficiency of individual elements in a system and potential modifications to overall operations to reduce system-wide operating costs. Once focus areas have been identified, options for improving the system can be developed. Some improvements can be as simple as monitoring power use at each of your facilities and then negotiating with your power provider to ensure each facility is on the most cost effective rate schedule.

Other examples of improvements that might be considered include changing the operation of current facilities to take advantage, where possible, of gravity supply to minimize energy needs and pumping during off-peak tariff rate periods. Rehabilitating, overhauling or replacing equipment that is not operating at its best efficiency point can reduce costs over the long term. Making other capital improvements such as adding storage can allow you to significantly change your operations and save you money.

System improvements that reduce your energy costs, in many cases, can also result in other benefits. Making greater use of existing storage volumes to offset the need for on-peak pumping can result in improved water quality through increased turnover and reduced water age. Capital improvements to reduce headloss and flow velocities will reduce the chance for scouring that may lead to red water events.

When assessing the benefits of an upgrade or replacement you want to be able to accurately assess current costs and compare estimated future costs on the same basis to allow a fair assessment of benefit. Collecting information from past energy bills and understanding current tariff rates will facilitate this. Both capital and future operating costs of the new or replacement equipment must be determined to allow an estimate of the payback to be calculated. This can then be used to help justify the implementation of recommended upgrades or modifications.

Extending your program to a system-wide operating plan

Once you have evaluated and addressed deficiencies in individual facilities, the next step is to look at system-wide operations to evaluate the most cost-effective way of operating on a day to day basis. An up-to-date, calibrated hydraulic model is an invaluable tool for assessment of improvement options, particularly when assessing their impact on the system as a whole.

A hydraulic model can allow you to evaluate the performance of existing or new facilities under different operating conditions. It gives you an opportunity to test capital improvement options to determine the potential pay-back prior to investing in expensive upgrades.

Documenting how the system currently operates under different conditions is an important first step – the hydraulic model should be calibrated under extended period simulation (EPS) conditions for both low and high demand conditions, and potentially also for transitional situations (such as spring and fall). A hydraulic model also gives you an opportunity to simulate past system operations under different seasonal demands (based on SCADA information) and evaluate where potential changes could be made to reduce energy use, or minimize energy costs.

Generally, system operators are not heavily involved in the development and use of your hydraulic model. Getting operators familiar with and confident in the model's performance helps ensure the involvement of operating staff in the development of proposed changes to system operations.

In terms of project implementation it is valuable to ensure all utility staff involved in the implementation understand the reasons for any recommended modifications and the expected benefits. Buy-in from all stakeholders – operators, engineering planning staff, finance staff and system managers – ensures everyone will be "on board" with the project which will increase the chance of success. Education and information sharing are key elements in the success of any energy efficiency program.

Getting the best bang for your buck – optimizing daily operations

More recently utilities have been turning to optimization tools to help them get more out of their systems. Some people are put off by the idea of optimizing their daily operations thinking that it requires a sophisticated SCADA system to be in place along with an automated control system. Although this may be the way of the future, significant return on investment can be achieved through analysis of a calibrated hydraulic model along with the input of operators to develop scenarios that can then be tested in the model prior to implementation in the field.

Introducing a formal optimization technique can enhance the analysis of potential improvement options, particularly when it comes to system-wide changes. Instead of launching into development of an expensive real-time or even daily operating optimization system, leveraging a simulation-optimization model to develop a "typical day" strategy provides an indication of what operators should aim to do under normal operating conditions and leaves room for operators to respond to emergencies.

The application of a simulation-optimization model allows system planners and operators to dramatically expand their consideration of alternative strategies and develop optimal strategies to meet system demands at least-cost. The optimization can consider life-cycle costs, pump efficiency and capital costs.

When applied to water systems, a formal optimization technique searches through different combinations of capital improvements and operating set points in a directed manner to meet a utility's objectives. For operations optimization, the decision variables are the individual pump start and stop times and the corresponding "trigger levels" for a tank that is supplied by a particular pump.

Optimization software can also consider capital upgrades, selecting pumps to meet the required operations with the best efficiency and overall reduction in life-cycle costs. Constraints are applied to ensure the system operates within the pre-defined limits for supply pressures, storage operation, maximum number of pump starts, flow velocity, etc.

A benefit of using an optimization tool is that alternative scenarios can be rapidly tested to determine the impact of changes to future operation costs, different system configurations, and changes to system demands.

Case Study

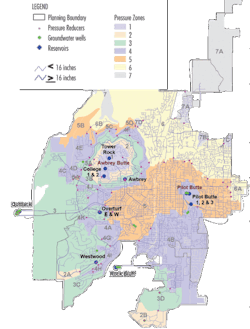

The City of Bend, located in Central Oregon, has a population of 81,000 and the water system serves approximately 60,000 residents. The city is fortunate to be located near water sources with excellent quality – groundwater from the substantial Deschutes Aquifer and surface water collected from the Cascade Mountains. Surface water supply is collected 13 miles from the city limits and delivered to the system via the Outback facility. Groundwater is extracted at nine well locations spread across the city.

The operation of the Bend system varies throughout the year. During winter, supply is primarily from the surface water source. Under summer demand conditions it is necessary to turn on a number of groundwater wells to supplement the surface supply.

The aims for improving system operations in each season differ considerably. The focus of a program to optimize summer operations was to minimize pumping energy costs by maximizing surface water use where possible. The city plans to invest in significant improvements to the aging surface water system, along with the implementation of a hydro-power generation facility, so maximizing use of this source is a high priority. For the winter operations optimization, improving turnover in key reservoirs was a major aim.

Baseline Scenarios

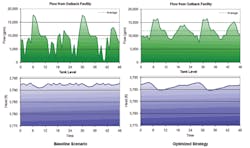

The optimization analyses were based on evaluation of a recently calibrated hydraulic model. Summer and winter models developed in the extended period simulation calibration effort were used as the baseline cases for comparison as they represent typical operating conditions for the existing system.

A study of historical water production and energy cost data was completed to determine the relationship between customer water use and energy costs. Annual power costs over the last few years for water facilities (wells, booster pumps, surface water facilities and disinfection) are on the order of $700,000.

The city is not subject to time-of-use tariff rates, so the key to reducing energy costs was minimizing overall energy consumption. This aligns with the city's desire to maximize surface (gravity) supply.

Problem Formulation

The City of Bend selected an optimization program offered by Optimatics. The company formulated the optimization program to consider a wide range of decision options aimed at achieving the objectives of reduced energy costs and improved reservoir turnover while maintaining hydraulic performance throughout the system.

Decision options included (1) introduction or modification of well and booster pump controls, (2) changes to existing control valve settings, (3) modification of zone boundary locations, and (4) minor capital improvements such as short piping connections and small booster pump stations.

Hydraulic design criteria were considered in the optimization and included establishing the required minimum pressure at customer connections and also how storage levels should vary throughout the day.

Conclusions

The results of the optimization runs demonstrated that there is opportunity to significantly reduce Bend's summertime operating costs with only minor capital upgrades. In addition, the solutions demonstrated operating strategies that could be used to maximize use of surface water in the existing system and improve reservoir turnover in the winter.

Three recommended strategies were presented to the city – two Summer Strategies with different wells operating but similar costs, and one Winter Strategy. Both Summer Strategies were shown to be 23% less costly than the Baseline Summer Scenario.

Recommendations included:

- Restricting flow into key reservoirs during periods of high demand to reduce peak flows in transmission lines.

- Adjusting PRV settings to facilitate transfer of flow from west to east, thus maximizing surface water supply.

- Boosting surface water between zones rather than pumping groundwater at higher heads, when possible.

- Addition of strategically placed control valves to force reservoirs to draw down during low demand periods.

A major key to the success of this optimization study was the fact that there was active participation and involvement from planning and operations staff from the city and the consultants carrying out the optimization analyses. The project included a number of opportunities for review of preliminary recommendations and discussion of their suitability for the Bend system.

Over the next few months, Bend operators will be working to implement the recommended improvements and will be closely monitoring the ability to maximize surface water use in the system which will indicate that savings in energy are being realized. WW

About the Author:

Elsinore Mann is a project engineer at Optimatics. Since joining the company in 2004, she has worked on numerous projects applying optimization to water system problems in the Australia, New Zealand, the UK, the US, and Canada. Mann relocated to Chicago in 2007 where she now works with Optimatics in their North American headquarters. She can be contacted at [email protected]

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles