Recovering Resources: Nitrogen and Phosphorus Recovery Integral to Nutrient Management Vision

By William Atkinson

Recently, the Water Environment Federation (WEF), Environmental Defense Fund and Johnston Foundation at Wingspread began working together to create a roadmap to implement a nutrient management vision, primarily for nitrogen and phosphorus.

The partnership's first report -- titled "Nutrient Roadmap Version 1.0," published in September 2014 -- noted that, "According to the U.S. EPA, more than 100,000 miles of rivers and streams, close to 2.5 million acres of lakes and ponds, and more than 800 square miles of bays and estuaries are affected by nitrogen and phosphorus pollution." In excess, these nutrients can lead to algal blooms, which cost the tourism industry about $1 billion per year, the Agency said.

Conversely, the report noted, "Fertilizers can be energy-intensive to manufacture, and the supply of some nutrients, such as phosphorus, is limited. Recovery not only prevents nutrients from entering waterbodies at point-source discharges but provides a supply of these essential resources."

As such, the report indicated that the partnership's "aspirational goal, or 25-year challenge, is informing the development of a Nutrient Roadmap, which will serve a short-term need for achieving smarter nutrient removal and recovery at water resource recovery facilities (WRRFs). The wastewater utility of the future is shifting toward recovering marketable resources rather than just treating wastewater."

Jeanette Brown, research assistant professor in the department of civil and environmental engineering at Manhattan College (New York), added, "As a general statement, wastewater treatment plants are becoming water resource recovery facilities." In fact, she noted, WEF now uses the abbreviation WRRF rather than WWTP or POTW (publicly owned treatment work) in all publications. "Several wastewater treatment plants in the U.S. have changed their names to reflect this change in philosophy," Brown said. "Rather than [thinking of it as] wastewater, they are taking advantage of everything embedded in the used water, including water itself, through direct and indirect water reuse. In addition, embedded in wastewater are two to four times the energy needed to treat it, as well as macronutrients such as nitrogen and phosphorus."

According to Thor Young, service line leader of wastewater treatment and recycling for GHD Inc. (www.ghd.com), many facilities are incorporating nutrient recovery to some degree. "Many nutrients from the influent wastewater are being captured in the biosolids, which are being used for land application or production of value-added biosolids products, such as compost and soil amendments, at many facilities," he said. "Other facilities use treated effluent for irrigation, so the nutrients in the effluent can be used by plants, reducing the amount of supplemental fertilizer addition."

Regarding the use of specialized processes to recover nutrients in a more purified form to be used as high-value fertilizer products, Young anticipates an increase in the amount of applications of these types of technologies. "However, I don't know if you will ever see the majority of wastewater treatment facilities using these types of processes because I don't think the economics are there to justify the extra capital and operating costs at many facilities," he said. "Unless there is a regulatory driver to install purified nutrient recovery systems, I don't think the payback period will be there for many facilities, particularly smaller ones."

Sarina Ergas, professor and graduate program director for the department of civil and environmental engineering at the University of South Florida (Tampa), believes that nutrient recovery from WWTPs will soon reach critical mass. "These facilities are implementing anaerobic digestion more and more," she said. Some of this is driven by increased restrictions on land application and landfilling of biosolids. Anaerobic digestion reduces the volume of biosolids that needs to be disposed of, while increasing the quality of the stabilized product and generating biogas that can be used as an energy source. Ergas suggested that once anaerobic digestion is implemented, however, the question becomes what to do with the side streams. "In areas like Florida that have strict nitrogen and phosphorus limits, returning the side streams to the headworks will negatively impact the mainstream process," she said.

As far as nitrogen is concerned, Ergas noted that this will likely mean higher energy and chemical costs, unless a sidestream treatment alternative is implemented. "Current commercially available nitrogen recovery technologies are not competitive with ammonia production via the Haber-Bosch process," she said. "Some people have suggested just keeping the nitrogen in the water and reusing the water for irrigation. However, there often isn't enough cropland near wastewater treatment plants to make this competitive."

Phosphorus Recovery Technology

While research and activity in nutrient recovery in general are gaining popularity, phosphorus recovery in particular is very promising and seems to be gaining a lot of traction. Already, a number of WWTPs are introducing methods to extract phosphorus from the wastewater rather than discharging it into the environment.

There are two primary types of extraction: chemical and biological. In the chemical method, the plant chemically treats phosphorus that is present in the wastewater, causing it to "fall out" of the solution for easier removal. In the biological method, the plant introduces bacteria into the wastewater, which turns the phosphorus into removable sludge.

Phosphorus recovery is not yet widespread, according to Young. One reason is because many of the process technologies on the market only work with a particular type of treatment train, such as biological excess phosphorus recovery (BEPR) facilities with anaerobic digestion. "Many treatment plants have existing liquid and solids process trains, which would exclude the economic use of some of the current technologies on the market," he said.

Still, interest seems to be growing for a couple of reasons, according to Ergas. "There are only a few large phosphorus deposits worldwide, and there are concerns that phosphorus fertilizer scarcity will significantly limit food production in the future," she said. Secondly, there is an effective technology available on the market for phosphorus recovery. "Recovery of phosphorus via struvite precipitation is the best alternative and has been very successful," Ergas added.

One company with such a technology is Ostara Nutrient Recovery Technologies (www.ostara.com). "Ostara has a business model that allows them to provide the capital cost for construction of [its] struvite precipitation reactor," said Ergas. "There are several other vendors of struvite precipitation equipment, but Ostara seems to be leading the industry, and I think it is largely because of this model."

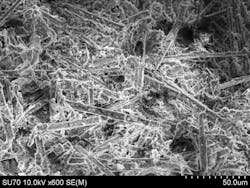

Brown is also impressed with the Ostara technology. "Currently, there are processes [that] recover phosphorus in the form of struvite," Brown said. But Ostara's Pearl Process provides a comprehensive approach to nutrient management, she added. The technology is based on controlled chemical precipitation in a fluidized bed reactor that recovers struvite in the form of highly pure crystalline pellets. Nutrient-rich feed streams are mixed with magnesium chloride -- and, if necessary, sodium hydroxide -- and then fed into the Pearl reactor, where minute particles, or struvite "seeds," begin to form. "These seeds, like pearls, grow in diameter until they reach the desired size (1.0 mm to 3.5 mm)," she said. In a municipal WWTP, according to Brown, up to 90 percent of the phosphorus and 40 percent of the ammonia load is removed from sludge dewatering liquid using this process. "The resulting product is marketed as a commercial fertilizer," she said.

According to Brown, there are currently only a few installations, but she believes more will come online. However, she noted a limitation: "Most of the treatment plants in the U.S. are quite small (less than 5 MGD), so while struvite recovery has its place, I do not see it reaching a critical mass," she said.

One facility already involved in phosphorus recovery is the Gold Bar Wastewater Treatment Plant, located at the Edmonton (Canada) Waste Management Centre. EPCOR Water Services, which owns the facility, is working with Ostara to build what will be the largest nutrient recovery facility in Canada. It will recover phosphorus from the nutrient-rich wastewater stream at the company's Clover Bar biosolids settling lagoon.

"Ostara's process is a green win for EPCOR," said Gavin Post, project manager for EPCOR, in a press release. "Implementing Ostara's nutrient recovery technology will help us reduce the amount of phosphorus that we are discharging into the North Saskatchewan River at the Gold Bar Wastewater Treatment Plant. As well, a reduction of phosphorus will significantly reduce the need to use chemicals to combat struvite buildup in our treatment system."

Besides recovering up to 85 percent of the phosphorus from the Clover Bar biosolids settling lagoons, the process will also recover up to 25 percent of the nitrogen. The recovered phosphorus and nitrogen will then be transformed into an eco-friendly, slow-release fertilizer. The process is expected to produce about 2,000 tons of fertilizer per year.

So what criteria should wastewater facilities utilize when considering nutrient recovery technologies? "The first step is to get a handle on the amount of nutrients present in the raw wastewater and the potential local market value of those nutrients in different forms," said Young. "The last thing you want to do is spend a lot of money and effort putting in a nutrient recovery system, only to discover that the market for the product is not there to support the price you need to make the operation sustainable."

About the Author: William Atkinson is a correspondent for WaterWorld Magazine. He has been a full-time freelance business magazine writer since 1976, specializing in infrastructure, sustainability, supply chain, risk management, and safety/health.